CRP Technology stands at the forefront of certified 3D printing solutions tailored for the Aerospace and UAV (unmanned Aerial Vehicle) sectors. Their Windform® series of composite materials is meticulously engineered to meet the rigorous demands of these industries. Featuring a diverse selection of carbon and glass fiber composites, Windform materials are both lightweight and exceptionally strong, making them perfect for crafting components that are ready for flight and capable of enduring the extreme conditions found in aerospace and space applications.

Reach Out to CRP Technology today for a complimentary sample for your upcoming aerospace project!

AS9100 & ISO 9001 Certified: Assurance of Quality for your Aerospace & UAV Initiatives.

CRP Technology’s facilities are rigorously certified to AS9100 (aerospace quality standards) and ISO 9001 (international quality management standard). these standards are meticulously applied and enhanced by specialized Quality Tracking software, enabling real-time monitoring of processes. This guarantees that every facet of our operations, from manufacturing to management systems, adheres to the highest standards.

Specialized FOD Prevention Zone

This designated area ensures a pristine and secure habitat for the production of your critical components, significantly reducing the risk of contamination.

Enhance Flight Duration & Performance

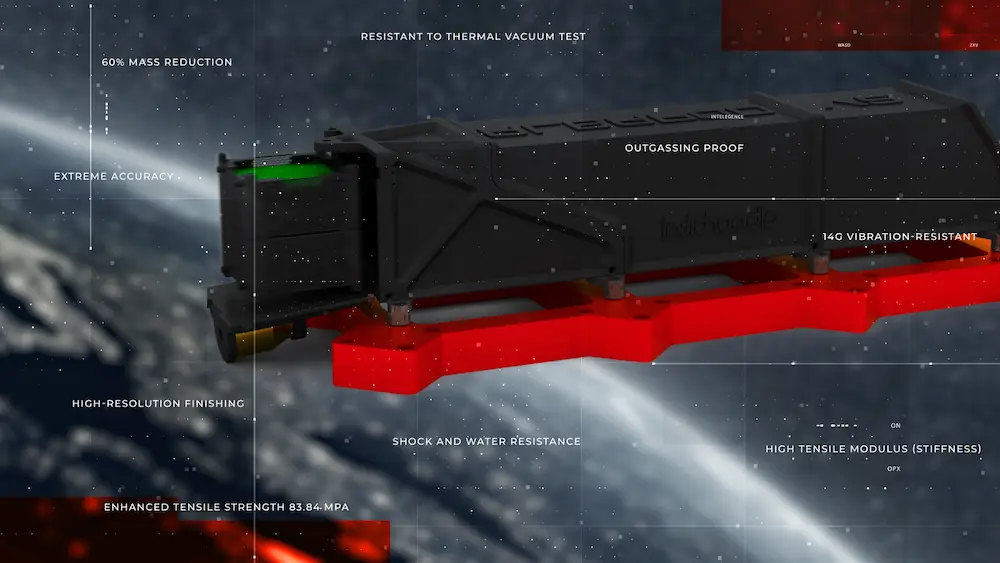

Windform® composites, made from carbon and glass fibers, provide the best weight-to-density ratio in the industry, resulting in drone components that can be up to 60% lighter than those produced through conventional methods.This directly leads to longer flight durations, increased payload capabilities, and lower fuel consumption for your UAV/UAS.

Pioneering 3D Printing in Aerospace & UAV

Windform® composites are not onyl lightweight but also incredibly resilient. Rigorously tested in real-world aerospace scenarios, they can endure extreme temperatures, chemical exposure, and high shock/vibration levels, including 14G. UAVs, satellites, and deployers crafted from Windform materials continue to operate successfully in long-duration missions, allowing you to tackle any challenging environment with assurance.

- Over 30 Years of Expertise: Leading the charge in additive manufacturing for aerospace and UAV sectors.

- Cutting-Edge Technology: Utilizing advanced 3D printing systems and Windform® composite materials.

- Assured Quality: AS9100 & ISO 9001 certified,ensuring the highest quality standards.

- Complete Services

Consultation in Design for Additive Manufacturing, Prototyping, Production, and Post-processing. - Trusted by Industry Leaders

Major aerospace agencies, and also UAV and aerospace manufacturers. - Global Presence: Catering to clients worldwide with three production facilities located in Europe,the USA,and the UAE,offering dedicated support.

For more details: SLS 3D printing for drone components

Exploring Windform Composite Materials

The windform composite family encompasses a broad spectrum of materials, providing solutions for nearly every drone design requirement.

Windform SL

A low-density polyamide material known for it’s high stiffness and excellent heat resistance, perfect for UAV airframes and arms.

Windform RS

A lightweight carbon-filled composite that boasts high stiffness and strength, along with excellent impact resistance—ideal for heavy-duty and mission-critical components.

Windform SP

An impact-resistant and waterproof material designed for environments with significant shock and vibration.

Windform XT 2.0

A space-grade material that offers exceptional strength and stiffness, suitable for both functional prototypes and production.

Windform FR1

A halogen-free flame-retardant composite compliant with UL 94 V-0 and FAR 25.853 standards.

Windform FR2

A glass fiber-filled flame-retardant composite with excellent electrical insulation properties.

Windform GT

A glass fiber-filled electrically insulated material that offers high flexibility and resistance to impact, shock, and vibration.

Windform LX 3.0

A next-generation glass fiber composite that provides an excellent surface finish, ideal for components requiring aesthetic appeal.

Windform RL

A rubber-like thermoplastic material that is resistant to repeated bending and torsion, providing good shock absorption.

Windform FX Black

An impact-resistant polyamide that mimics the behavior of polypropylene and ABS injection-molded parts.

Windform TPU

A thermoplastic polyurethane material that offers excellent flexibility and shock absorption, ideal for robotic components such as joints, pipes, and connection tubes.

Windform GF

A polyamide filled with aluminum and glass fibers, providing excellent surface definition, suitable for intake ducts and fuel systems.

To discover which Windform material best suits your submission, explore our product selector.

Applications & Use Cases

Modular Drone Innovations

Utilizing two carbon fiber reinforced thermoplastic composites, Windform SP and Windform XT 2.0, functional and critical components of the Tundra flight-ready professional drone prototype were developed. These modular parts, including arms and body, successfully met design specifications, including spatial constraints and extreme flight conditions, enabling system optimization.

- Outstanding performance: Windform SP and XT 2.0, carbon fiber reinforced materials, provide superior strength, lightweight characteristics, and high thermal stability compared to conventional manufacturing techniques.

- Design flexibility: The modular configuration of the drone’s arms and body allows for enhanced customization and optimization to fulfill specific mission and operational requirements, including various payload options.

- Durability under pressure: Windform components not only passed rigorous testing but also excelled in real-world operations, including spatial limitations and extreme flight conditions, showcasing their reliability and suitability for demanding applications like professional drones.

Wind Tunnel Model of the Leonardo Tiltrotor AW609

CRP Technology produced various external components (nose and cockpit, rear fuselage, nacelles, external fuel tanks, fairings) for the 1:8.5 scale wind tunnel model of the Leonardo HD tiltrotor AW609 prototype,utilizing Carbon fiber filled Windform XT 2.0 as the manufacturing material.

Upon assembly, these primary components crafted from Windform underwent a series of dedicated low-speed wind tunnel tests, demonstrating exceptional mechanical and aerodynamic properties.

Tail Rotor Gearbox Housing for Unmanned Helicopter

Windform XT 2.0 was chosen as the preferred material for the tail rotor component of the Flying-Cam’s Finding helicopter UAV. This component required enhanced rigidity and the ability to endure the stress of being attached to the tail boom. The weight-to-strength ratio of this advanced material made it the ideal choice for this challenging application.

Rocket Propulsion Systems for Small Satellites

Windform composites have been utilized in the first known functional additive manufactured rocket motor system, specifically designed for the small satellite sector as a multi-start thruster. This complex and functional hybrid propulsion system meets stringent mechanical requirements for space applications, capable of multiple restarts and tested at a peak thrust of 6.2 lbf for a duration of 16 seconds.

While we can only share a limited number of real-world applications due to confidentiality agreements, Windform materials are extensively utilized across various sectors, including UAV-UAS, Aerospace, and Avio industries.