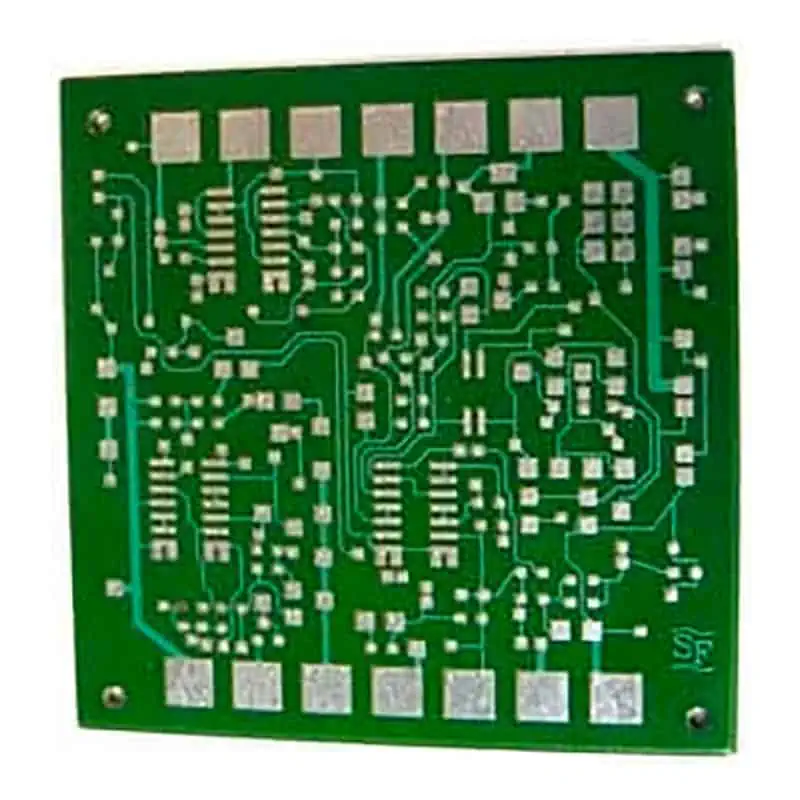

San Francisco Circuits (SFC), a leader in PCB (printed circuit board) manufacturing, assembly, and testing services tailored for unmanned systems and robotic technologies, has unveiled a complete checklist aimed at reducing errors throughout the various phases of bareboard PCB production.

Explore the complete checklist on SFC’s official website.

This resource has been crafted from extensive experience by the SFC team, drawing on successful practices in delivering high-quality PCB orders from inception to completion. It serves as an invaluable reference for obtaining precise estimates when placing orders.

The checklist encompasses several critical components necessary for effective manufacturing:

- Material specifications

- plating surface requirements

- Soldermask specifications

- Chosen surface finish

- Silkscreen details

- Vendor UL logo and date code stipulations

- Types of tolerances

- Fabrication and acceptance criteria

- Manufacturing documentation

- Fabrication specifications

- Bill of materials, including part numbers and annotations

- Type of assembly

When preparing for the production of a printed circuit board, meticulous planning is essential to minimize potential errors. SFC’s checklist is a vital resource for facilitating a smooth manufacturing experience.