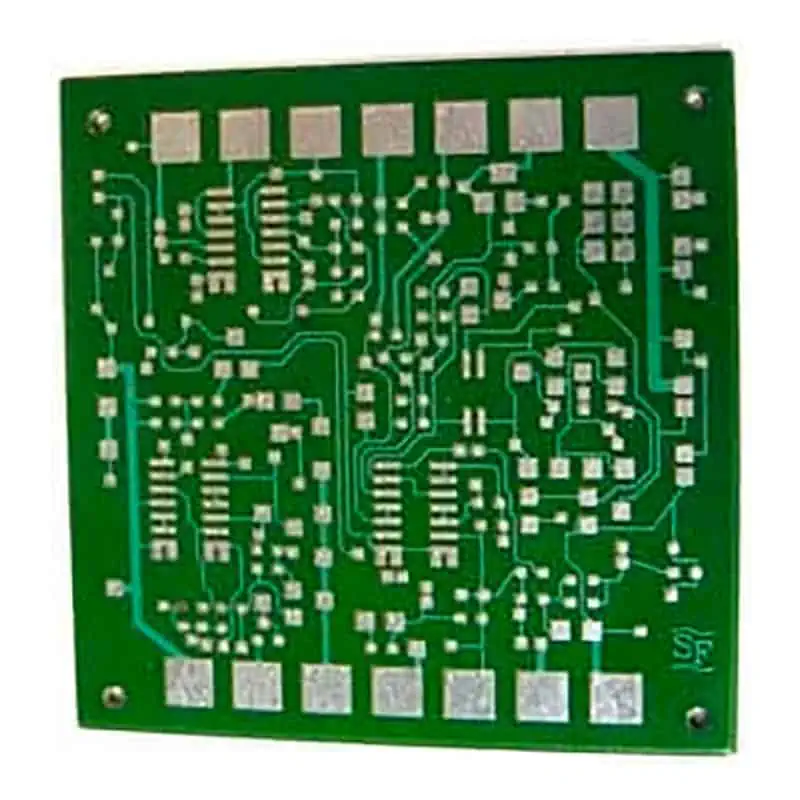

San Francisco Circuits (SFC), a leader in PCB (printed circuit board) manufacturing, assembly, and testing services tailored for unmanned systems and robotic technologies, has published a comprehensive guide that highlights essential considerations for choosing the appropriate surface finish for specific PCB applications.

Explore the complete guide on the San Francisco Circuits website.

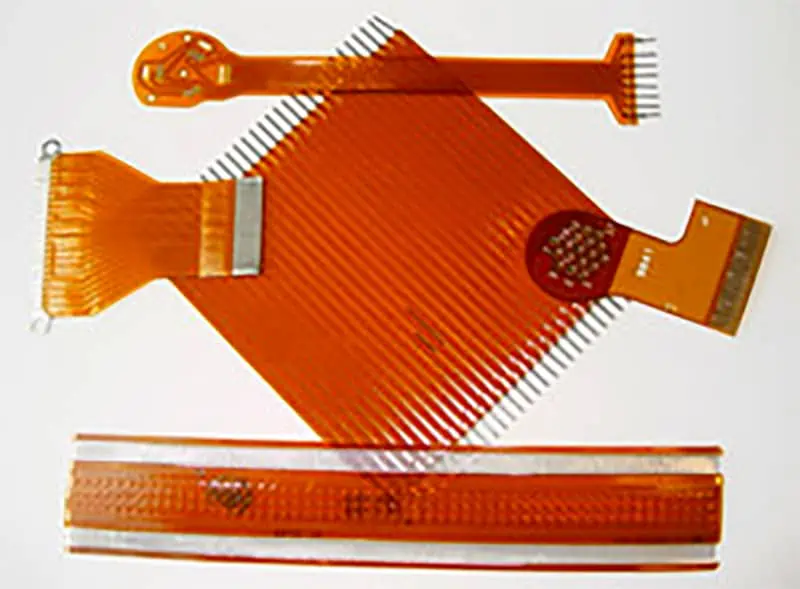

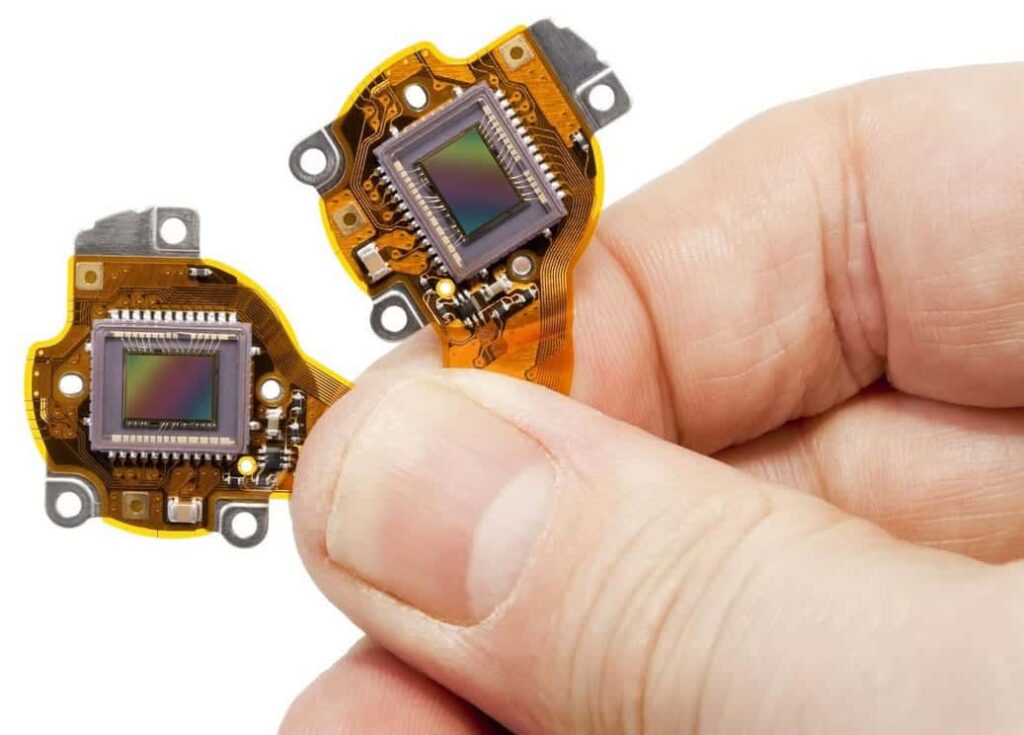

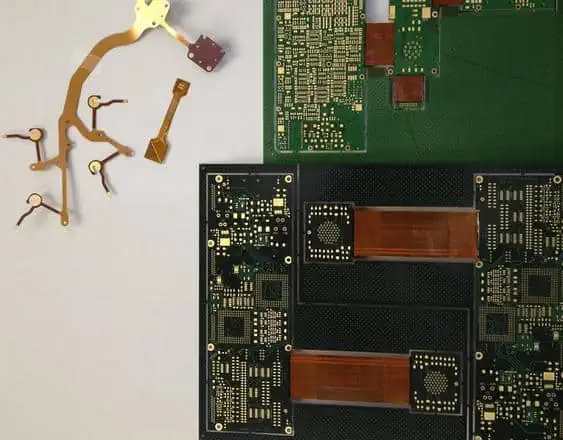

The surface finish plays a vital role in ensuring a dependable connection between the PCB and its electronic components. It provides a solderable surface for component attachment and safeguards exposed copper from oxidation.

this guide elaborates on the benefits, drawbacks, characteristics, and typical uses of various PCB surface finish technologies, including:

- ENIG (Electroless Nickel Immersion Gold)

- ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold)

- Electrolytic Nickel/Gold – Ni/Au (Hard/Soft Gold)

- Immersion Silver

- White Tin/Immersion Tin

- OSP (Organic Solderability Preservatives)

- Lead-Free HASL (Hot Air Solder Leveling)

Choosing the right surface finish for a PCB is essential for optimizing both performance and reliability. Numerous factors must be taken into account, including cost, environmental conditions (such as temperature, shock, vibration, and RF interference), component density, and production volume. For further insights, read the complete guide here.