Countries are working towards achieving energy autonomy, resilient supply chains, and carbon neutrality by the year 2050. A vital aspect of these goals is the secure storage of biofuels, oils, liquid gases, hydrogen, methanol, ammonia, and carbon.

Nevertheless, these substances pose considerable hazards if they leak, vaporize, or ignite. Therefore, it is essential for storage tanks to undergo frequent inspections to identify cracks, leaks, corrosion, erosion, and general wear and tear.

Non-destructive testing (NDT) stands out as one of the most effective and reliable methods for assessing the structural integrity of tanks and identifying even the most minor defects at any depth.

Drones such as the Voliro T can considerably improve NDT inspections, potentially saving up to 400 hours that would otherwise be spent on scaffolding setup and dismantling. Below, we explore common NDT techniques for storage tank inspections and how Voliro drones facilitate both external and internal assessments of aboveground tanks.

Importance of Routine Storage Tank Inspections

In the absence of regular inspections, storage tanks can become compliance liabilities and pose serious safety threats. Unnoticed defects can lead to hazardous leaks or devastating explosions, which can harm the environment, cause health issues, and even result in fatalities among workers.

For example,SABIC,a leading global chemical producer,faced a naphtha leak at its European facility due to undetected damage on a storage tank’s roof. this incident resulted in one death and multiple injuries. Following an inquiry, SABIC incurred a €10 million fine and ongoing damage to its reputation.

Neglecting this critical area can lead to hefty regulatory fines,protracted legal battles,and negative publicity for companies.

Regulatory standards are also tightening. By 2026, individuals responsible for environmental damage to ecosystems, water, soil, or air quality may face imprisonment under new EU legislation. In the United States, authorities are considering fines ranging from $900 to $1,500 per ton of excess methane emissions, including those from oil and gas storage facilities.

to mitigate the risk of leaks, it is crucial to conduct regular inspections of storage tanks to identify any damage or deterioration.

Common causes of storage tank leaks include:

- Corrosion and erosion

- Environmental influences

- significant wear and tear

- component failures (e.g., unsealed roofs)

- Material incompatibility (e.g.,carbon steel reacting with acidic substances)

- Excessive operational pressure

- Inadequate temperatures (due to faulty heating/cooling systems or poor insulation)

- Human error or improper handling

Storage Tank Inspection Standards

Inspection protocols are determined by the manufacturer’s guidelines,local regulations,or industry standards (for registered members).

Key standards for aboveground tank inspections include:

- USA: API 653, Env-Or 300, EPA’s SPCC, STI SP001

- Europe: EEMUA 159, EN 14015

- Internationally: ISO 16961:2015, ISO 24489:2024

The type and frequency of inspections depend on factors such as tank size, design, contents, location, previous inspection results, operational mode, and corrosion rates. Certified inspectors can provide recommendations for optimal inspection schedules and protocols.

External Inspections

In-service storage tanks should be subjected to monthly external inspections by the owner or thier representative. This includes evaluating the condition of the roof, walls, bottom, connections, pipes, ladders, drain valves, and the surrounding area.

Look for abnormalities such as leaks, stains, discoloration, mold, cracks, or corrosion. Some insulation or coatings may need to be removed for accurate measurements. Check for irregularities like bulges, deformations, or settlement issues on the shells and roofs.Inspect decked areas for oil accumulation.

Annual ultrasonic wall thickness measurements are essential.According to STI SP001, tanks must be taken out of service if at least 5% of any 12×12-inch (30×30 cm) area has less than 50% of its original thickness remaining. Drones like the Voliro T can expedite thickness tests with precision using a mounted dry film thickness gauge.

Following significant events such as visible leaks, fires, or severe storms, immediate inspections are crucial, particularly for roof drainage systems.

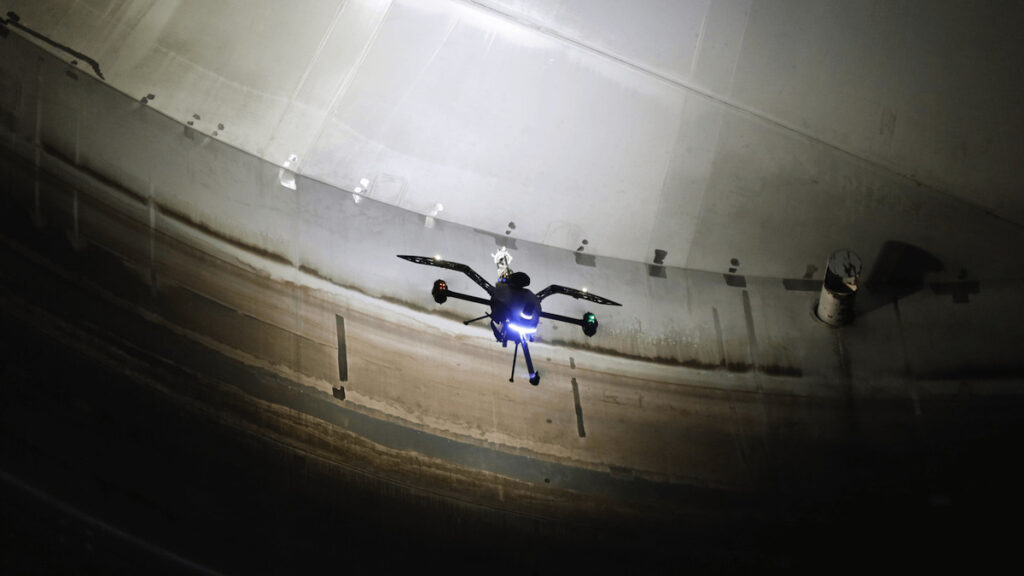

Measuring the outside wall thickness of a large storage tank using the Voliro T drone

Internal Inspections

Before conducting internal tank inspections, it is necessary to drain all contents and residues, ensuring adequate oxygen levels, safe entry points, and non-explosive conditions. Internal inspections help identify defects such as pitting, welding flaws, lap joint issues, and corrosion. inspectors document the locations, sizes, and depths of defects.

Drones are increasingly utilized to capture video footage of tank interiors, eliminating the need for manual climbing. Devices like the Voliro T can gather thickness readings, identify corrosion, and detect defects such as porosity and debonding.

Internal inspection intervals are as follows:

- Ground-contact tanks: initial inspection after 10 years

- Elevated tanks: initial inspection after 20 years

- Subsequent inspections: every 5 years for gasoline tanks, every 10 years for tanks storing other fuels and oils

Non-Destructive Testing Techniques for Storage Tanks

NDT is the preferred method for assessing the durability and integrity of storage tanks.Standards like SP001 recommend visual, radiographic, ultrasonic, hydrostatic, and acoustic emission tests, even though the choice depends on the specific tank and its requirements.

Visual Inspection

This essential method relies on direct observation to identify surface-level issues, such as cracks, bulges, or corrosion.Drones can access elevated areas more efficiently than customary methods.While visual inspections are limited to visible defects, they frequently enough inform the use of more advanced NDT techniques.

Ultrasonic Testing

Ultrasonic testing (UT) employs high-frequency sound waves to measure wall and coating thicknesses. It can detect flaws as small as 0.05 mm and is effective on various materials, including metals, plastics, and polymers.

Drones equipped with UT probes, such as the Voliro T, can take up to 200 readings per hour, inspecting walls, roofs, and floors without requiring direct access.

The Voliro inspection drone is outfitted with two types of UT inspection tools:

- voliro UT probes feature echo-to-echo and pulsed echo test modes, offering a thickness range of 4-150 mm.The high-temperature UT probe can perform high-precision scanning even at operating temperatures of 0 – 260 °C / 32 – 500 °F.

- Voliro EMAT probe generates sound impulses without direct contact, making it ideal for inspecting corroded, dirty, and uneven surfaces, such as those found in operational storage tanks.

Eddy Current Testing

Eddy current testing identifies near-surface flaws in conductive materials like steel. Pulsed eddy currents (PEC) can detect corrosion hidden beneath insulation without direct contact. Voliro plans to launch a drone-mounted PEC payload in late 2024, enhancing inspection capabilities for insulated tanks.

Voliro T equipped with the PEC payload

Dry Film Thickness Measurement

This technique assesses protective coatings, such as epoxy or zinc. Voliro drones with DFT probes enable rapid measurements, ensuring coating integrity even instantly after submission.

Acoustic Emission Testing

Acoustic emission testing (AET) detects active defects by converting noise vibrations into data. It is indeed highly sensitive but can be influenced by external noise interference.

Other methods, such as liquid penetrant testing, electromagnetic particle testing, and radiographic testing, are also available, though they are more suited for smaller tanks or laboratory environments.

Read the original article >>