BotBlox

stands at the forefront of developing robust and compact network infrastructure tailored for drones and robotics. The company specializes in Ethernet technology, offering highly optimized network components that excel in size, weight, and power (SWaP) while delivering rapid data transmission in a compact format. these components are designed for direct integration into unmanned aerial vehicles (UAVs),unmanned ground vehicles (UGVs),and various robotic systems.

botblox’s Standard Series of OEM boards employs industrial-grade materials and superior manufacturing techniques to produce some of the smallest Ethernet solutions available, making them perfect for a diverse array of commercial drone and robotics applications, even in extreme temperatures up to 80°C.

In this exclusive interview, Josh Elijah, the Founder and CEO of BotBlox, provides valuable insights into the company’s Ethernet technology and its significance in the unmanned systems sector.

How does Ethernet technology enhance the performance and dependability of drones in challenging environments?

Performance and dependability, while interconnected, are distinct concepts. Performance pertains to how well a system achieves its intended function—such as range, video quality, or control stability in a UAV. Dependability, conversely, refers to the system’s ability to consistently operate over time and under various conditions, including failure rates and downtime.

Ethernet plays a crucial role in drones as a dialog technology, akin to USB, CANBus, or WiFi. When constructing a drone, system integrators must select a communication bus to link the various components. This decision substantially influences the drone’s performance and reliability, as the communication bus functions like the nervous system, relaying data between its components. So, why opt for Ethernet?

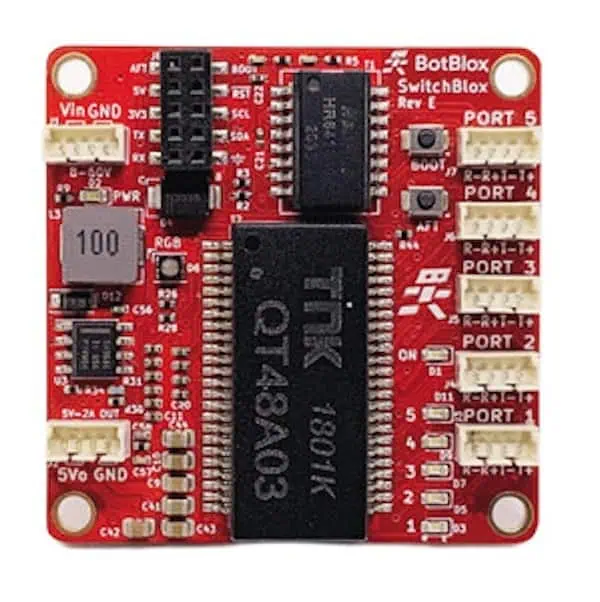

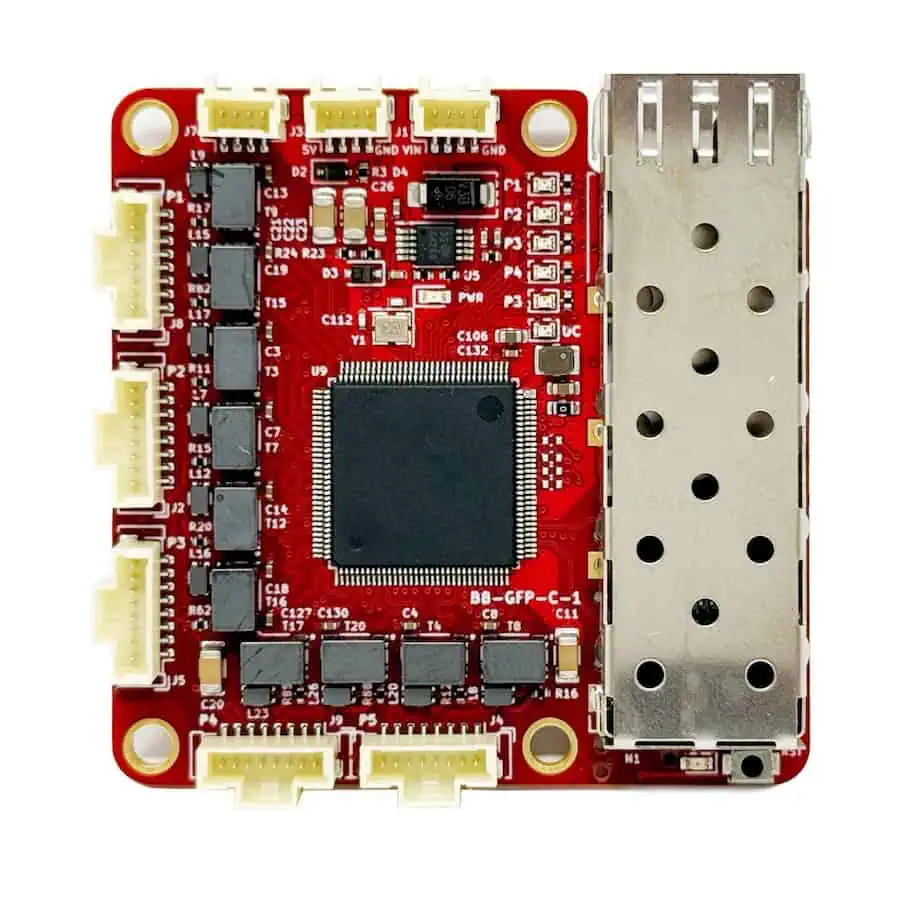

Puck Maxi: A managed, 8-port Gigabit + 3 10G SFP Ethernet switch in a compact and rugged design.

starting with dependability, while CANBus is renowned for its robustness in automotive applications due to features like differential signaling and noise immunity, Ethernet provides similar reliability and more.

Ethernet not only incorporates differential signaling and error-checking mechanisms but also includes advanced reliability features such as error detection and recovery protocols.

In comparison to USB, which requires precise connectors and notable software overhead for reliable operation, Ethernet is much simpler to implement and maintain in harsh conditions.

regarding performance, Ethernet outperforms nearly all other communication buses with its high data rates (up to 10 Gbps) and auto-negotiation capabilities. As a notable example, Ethernet facilitates the smooth transmission of high-resolution video streams or large datasets essential for sophisticated drone operations. The leap from a 10 Mbps to a 1 Gbps video feed is substantial, especially as drones evolve to become more autonomous and intricate.

A drone’s communication bus must endure extreme conditions, such as wide temperature fluctuations, without relying on high-tolerance electronics or cumbersome software. It must achieve this while supporting high data rates to prevent bottlenecks. ethernet excels in both aspects, making it the preferred communication technology for high-performance, reliable drones in demanding environments.

Note: While CANBus operates with just two wires,ethernet typically requires four wires (for 100 Mbps) or eight wires (for 1 Gbps),which can complicate design.This issue is being addressed with Single Pair Ethernet (SPE), which reduces wiring to just two conductors while maintaining Ethernet’s advantages. BotBlox is among the few companies actively developing SPE solutions tailored for drones and similar applications.

What obstacles do drone manufacturers face when integrating compact Ethernet solutions, and how does BotBlox tackle these challenges?

Drone developers frequently encounter “integration hell”—the challenge of creating a cohesive system from a mix of off-the-shelf and custom components. This issue is exacerbated when components utilize different communication protocols or incompatible Ethernet connectors and pinouts. moreover, there is a scarcity of rugged interconnect and networking hardware optimized for the stringent SWaP requirements of embedded platforms.

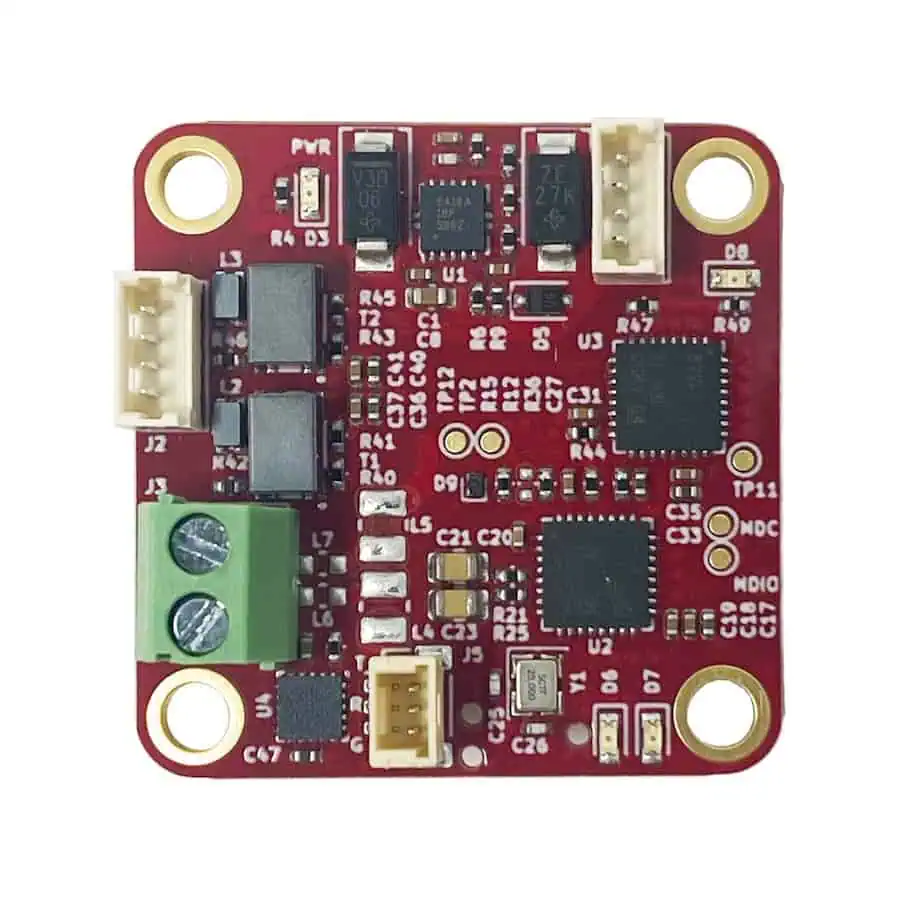

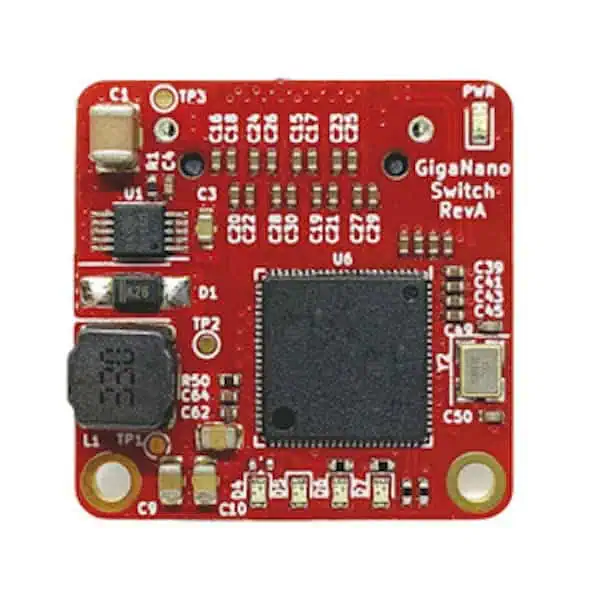

gigablox Nano: A four-gigabit Ethernet switch in a compact one-inch square.

At botblox, addressing these challenges is our core competency. We design compact, rugged Ethernet hardware specifically for drones and embedded systems. By concentrating solely on Ethernet, we ensure our products are optimized for size, weight, and durability.

We perform environmental qualification testing to ensure reliability in harsh conditions, allowing developers to concentrate on enhancing their drones without the burden of networking infrastructure concerns. Our products are engineered to withstand flight, ground movement, submersion, and even crashes—facilitating seamless ethernet integration for our clients.

Why is Ethernet deemed essential for drones operating in industrial and commercial sectors?

Not every drone necessitates Ethernet, as simpler systems can operate effectively with slower communication buses. However, Ethernet becomes crucial for high-performance drones that require greater internal bandwidth. For drones engaged in industrial or commercial tasks—where real-time data processing, high-resolution video feeds, or substantial data transfers are vital—Ethernet’s speed and reliability are indispensable.

Can you elaborate on how Ethernet facilitates high-bandwidth communication in drones?

Ethernet boasts several features that make it ideal for high-bandwidth communication in drones:

- High Data Rates: Ethernet supports speeds exceeding 10 Gbps, with ongoing advancements like 40GBASE-T aiming for 40 Gbps. This ensures drones can manage data-intensive tasks such as real-time video processing and sensor integration.

- Robust signaling: ethernet employs a straightforward yet effective electrical signaling method, facilitating integration in challenging environments without the need for highly matched connectors or complex routing.

- Advanced Networking Features: Ethernet’s capabilities encompass VLANs (Virtual LANs), QoS (Quality of Service), link aggregation, and redundancy. As an example, QoS prioritizes critical telemetry data over less urgent traffic, enhancing operational reliability.

- Precision Timing: Advanced protocols like PTP (Precision Time Protocol) enable accurate internal timing, which is crucial for drones operating in GPS-denied environments.

No other communication bus can match Ethernet’s combination of bandwidth, fault tolerance, and network management capabilities.

What specific challenges does BotBlox address for drone developers seeking compact and efficient Ethernet switches?

The primary challenge lies in establishing a reliable internal network within the stringent constraints of a drone’s size, weight, and power. At BotBlox, we specialize in crafting compact, rugged Ethernet switches that integrate seamlessly into drones, allowing developers to focus on enhancing their systems rather than creating custom networking solutions. Our products deliver advanced networking features in the smallest possible form factors, enabling drone developers to concentrate on their drone’s capabilities rather than the network.

Can you share an example of how BotBlox’s Ethernet solutions improve drone functionality for tasks like mapping, inspection, or autonomous navigation?

One notable case involved a client developing an imaging payload for large aircraft. This payload included multiple cameras (both visible and infrared) with varying fields of view, generating substantial amounts of video data for applications such as wildfire mapping and search-and-rescue missions.

Utilizing our UbiSwitch, the team achieved seven gigabit Ethernet streams with link aggregation for redundancy on key cameras. They connected the payload to the aircraft via a 10 Gbps fiber link and employed SPEBlox for telemetry and control, leveraging single-pair Ethernet to minimize wiring complexity and enhance reliability. this solution reduced weight, improved functionality, and streamlined system integration—critical factors for the project’s success.

How does BotBlox foresee its Ethernet solutions influencing the broader adoption of standardized communication protocols in the drone industry,and how will Ethernet technology evolve to meet future demands?

As drones become increasingly sophisticated,the need for unified network infrastructures intensifies. Ethernet is well-positioned to emerge as the standard communication bus for drones, and BotBlox is at the forefront of this movement. We will continue to innovate, reducing the size and weight of ethernet hardware while introducing new features to support emerging applications in drones and robotics.

It has been a pleasure discussing the integration of botblox’s

Ethernet technology within unmanned systems

. Thank you for sharing these insights.