Dymax 9771 is gaining traction in the aerospace and defense industries due to its exceptional ability to safeguard critical electronic components in extreme conditions.

This conformal coating boasts certifications such as MIL-I-46058C and is included in NASA’s MAPTIS database, making it suitable for a variety of applications, from satellites to unmanned aerial vehicles (UAVs).

In this interview, Virginia Hogan, Senior Manager of Business Advancement for Aerospace & Energy at Dymax, explains how the coating’s light- and moisture-curing properties ensure reliable performance, thorough coverage, and enhanced manufacturing efficiency for densely packed electronic assemblies.

Why is Dymax 9771 Capturing Interest in Aerospace and Defense?

Dymax 9771 is engineered to fulfill the stringent demands of high-reliability electronics utilized in satellites, guided missiles, UAVs, and autonomous defense systems. It holds MIL-I-46058C certification,is cataloged in NASA’s MAPTIS materials database (ID #09841),and adheres to MIL-STD-883 Method 5011 and NASA’s ASTM E595 low outgassing standards.

These certifications are crucial for engineers tasked with selecting materials that demonstrate reliable performance under mechanical, thermal, and vacuum stress conditions.

How Does Light-Curing Technology Compare to Conventional Methods?

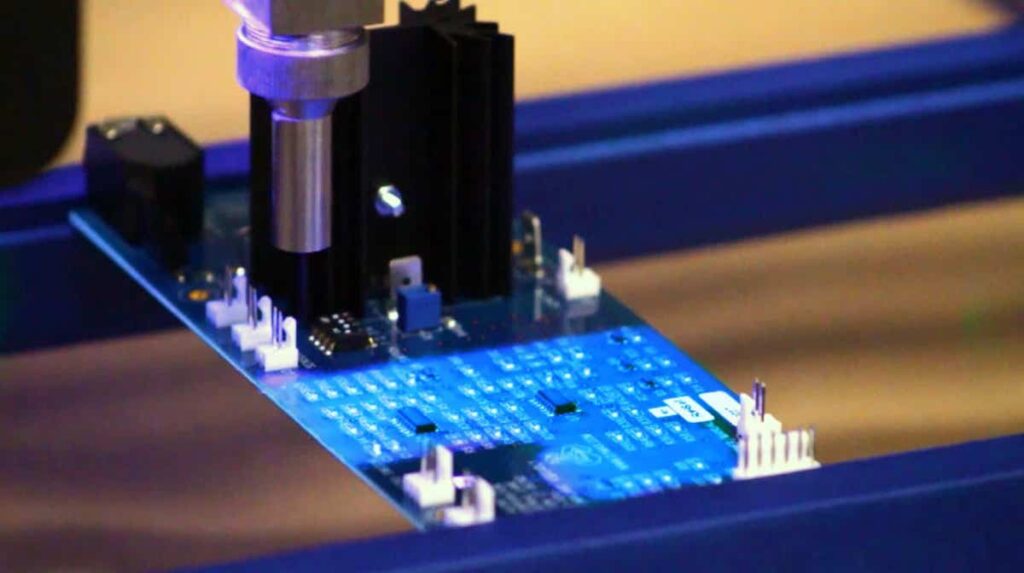

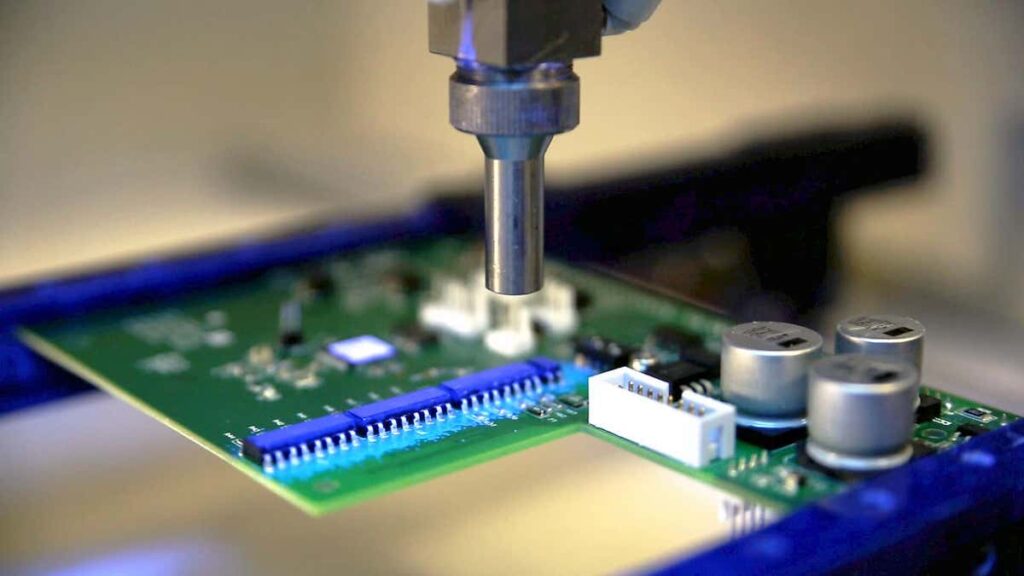

Conventional conformal coatings typically depend on solvent evaporation followed by thermal curing,wich can prolong processing times and introduce inconsistencies. In contrast, Dymax 9771 employs UV/Visible light to trigger crosslinking, achieving curing in mere seconds. This light-curing approach facilitates quicker processing, tighter control over curing parameters, and uniform coating performance.

Moreover, the absence of added solvents in the coating mitigates emission control issues and minimizes risks associated with solvent entrapment or reflow. These attributes are notably vital for missile electronics, space-qualified hardware, and systems requiring stringent process validation.

What Protective Features Does Dymax 9771 Offer for Aerospace and Unmanned Systems?

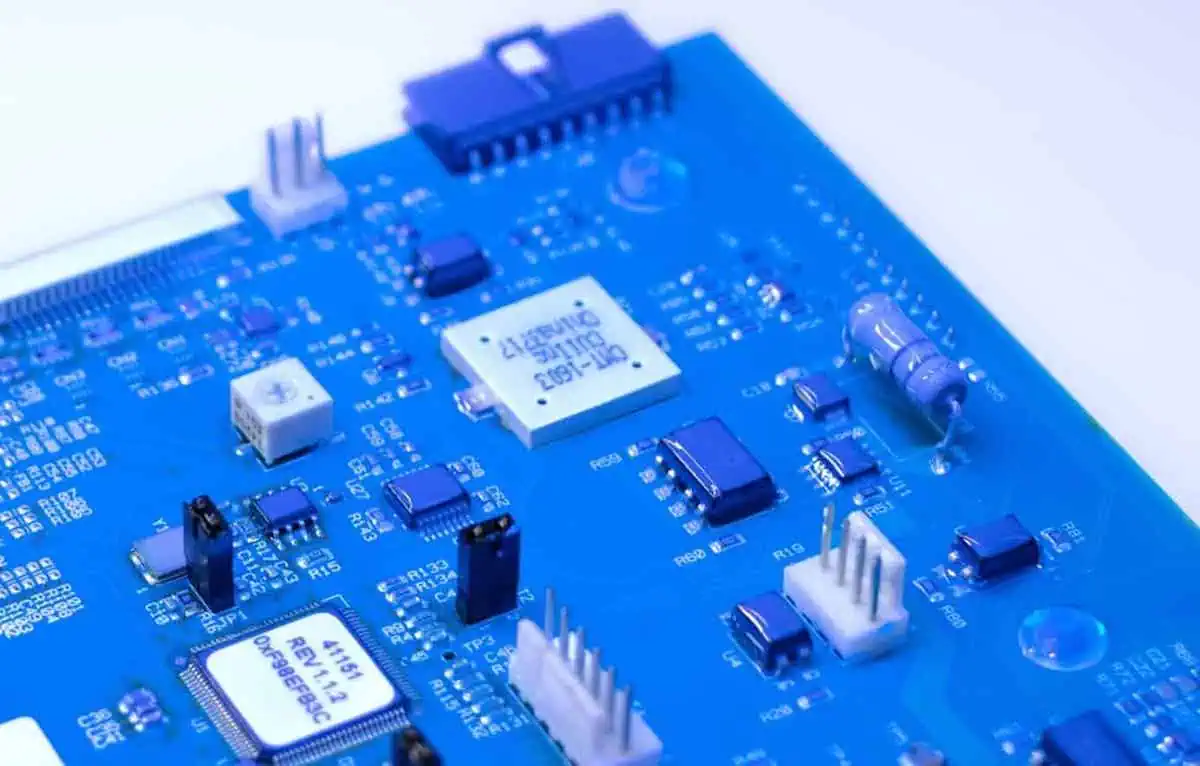

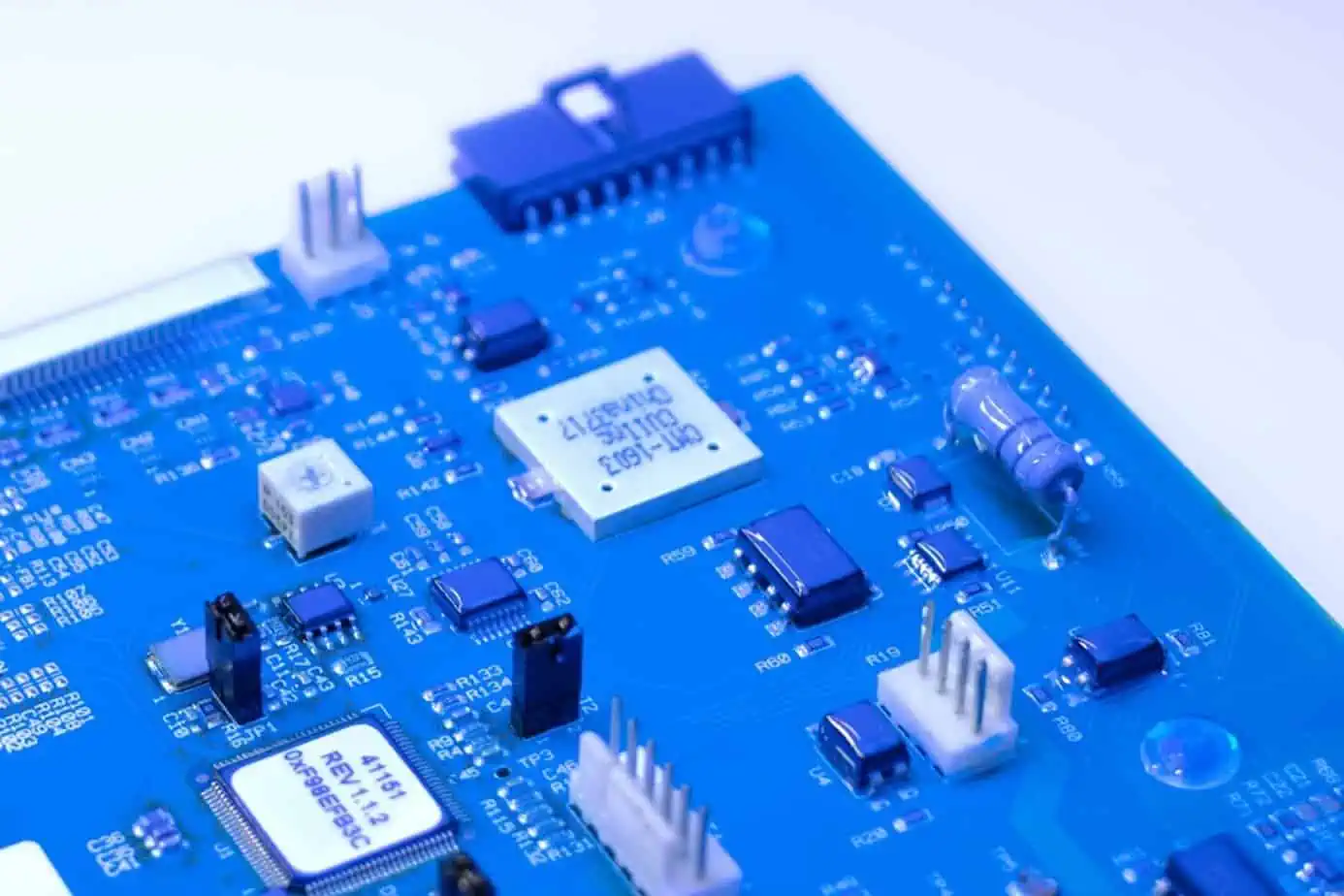

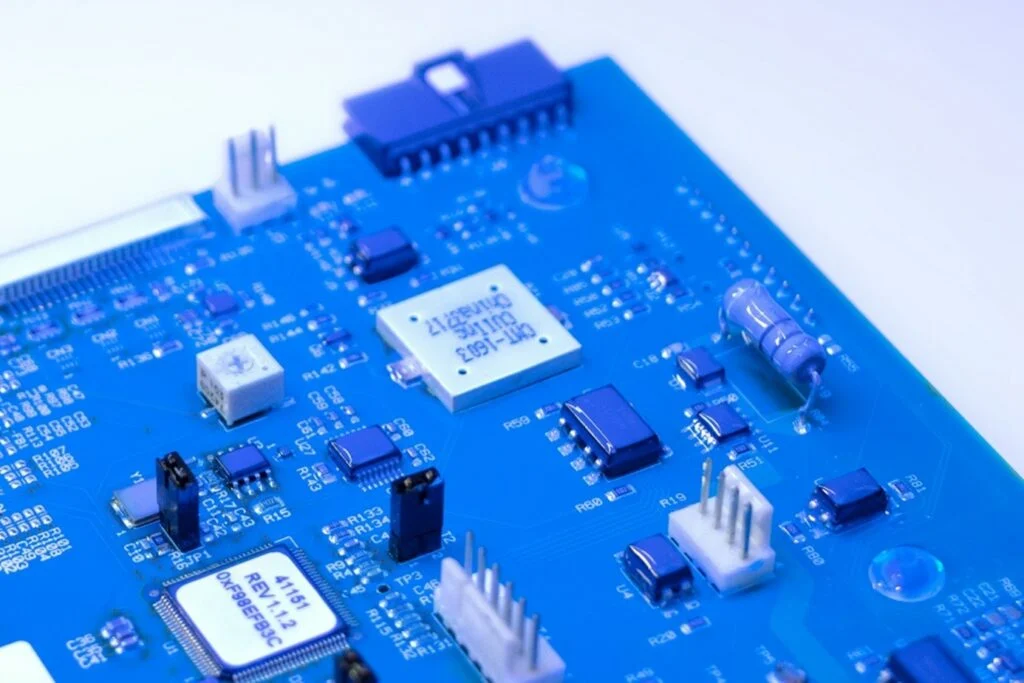

This coating provides electrical insulation and a robust physical barrier, reducing exposure to moisture, dust, corrosive substances, and thermal fluctuations. It also ensures strong adhesion under conditions of vibration and thermal stress, which is critical for high-altitude and mobile platforms.

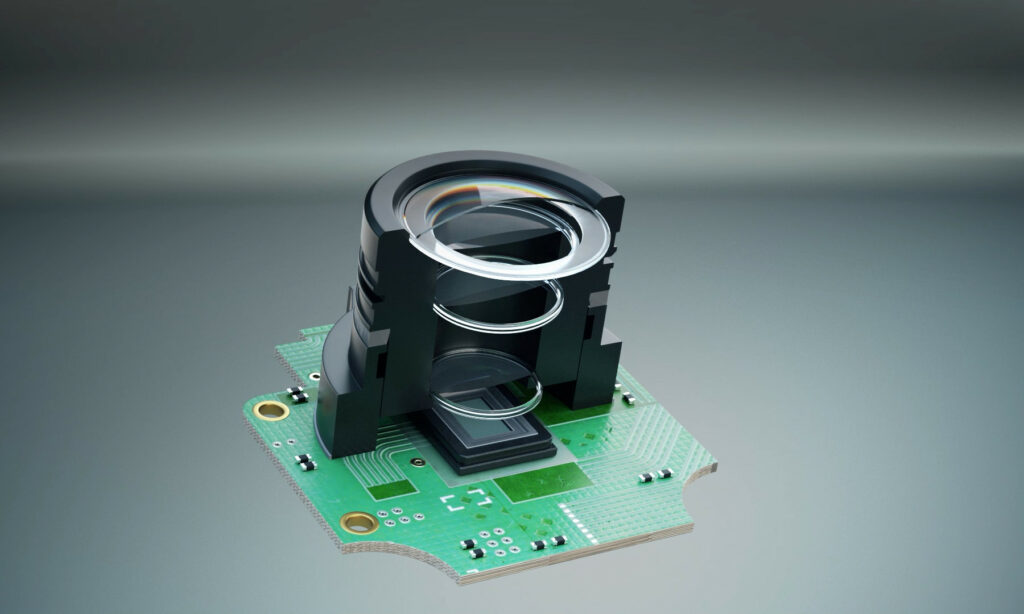

The dual-cure mechanism—comprising an initial UV/Visible light cure followed by a secondary ambient moisture cure—guarantees polymerization in areas that are shielded from light, such as beneath components or within densely populated circuit boards. This dual-cure feature is essential for achieving uniform coverage in multi-layer or high-density PCBAs used in space, missile, and UAV applications.

What Do MIL-I-46058C Certification and NASA MAPTIS Listing Indicate?

The MIL-I-46058C certification confirms that the coating meets stringent criteria for dielectric strength, humidity and corrosion resistance, thermal stability, and mechanical versatility. These benchmarks are standard references in the procurement processes for defense and aerospace sectors.

Furthermore, dymax 9771’s inclusion in NASA’s MAPTIS database (ID #09841) verifies that it has successfully met the ASTM E595 standards for Total Mass Loss (TML) and Collected Volatile Condensable Materials (CVCM). This is particularly crucial for applications in vacuum environments,where volatile substances can compromise optical surfaces or sensitive components.The MAPTIS listing simplifies material selection for flight hardware, ensuring traceability.

What Manufacturing and Compliance Benefits Does Dymax 9771 Provide?

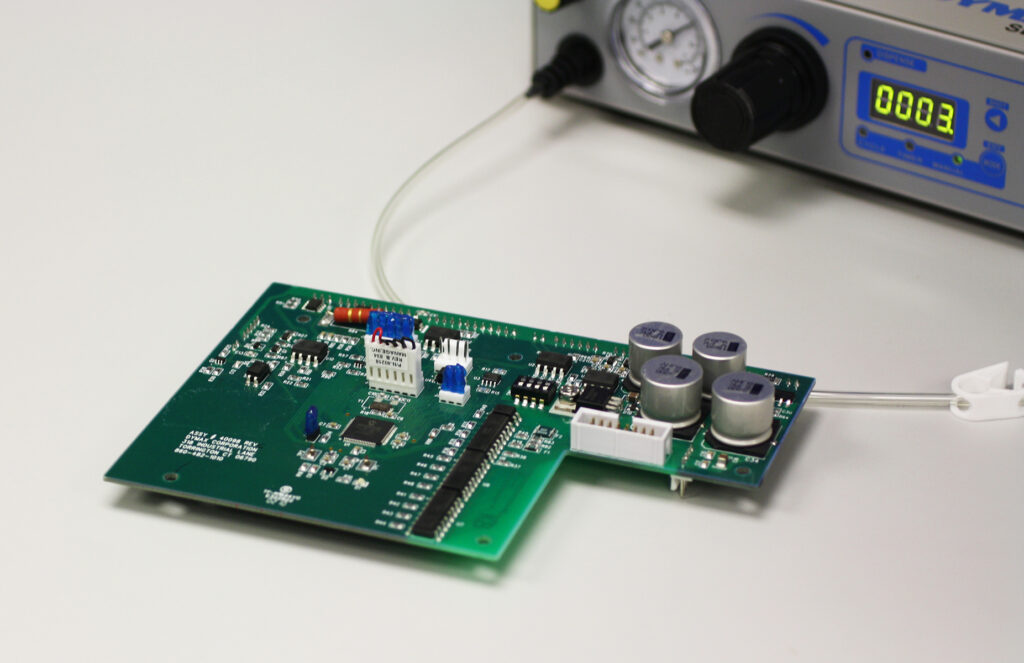

This coating is a single-component system, which eliminates the need for mixing or purging. It cures in seconds under UV/visible light, and the dual-cure feature guarantees complete curing even in hard-to-reach areas. It is indeed halogen-free, compliant with RoHS2 and REACH regulations, and contains no added solvents, thereby supporting both environmental and operator safety standards.

A built-in fluorescent tracer allows for inspection under black light,enabling manufacturers to confirm uniform coverage before final assembly or deployment. These features enhance process efficiency and reduce the risk of defects in both high-volume production and low-rate,high-criticality projects.

Dymax 9771 is meticulously designed to meet the technical and regulatory demands of aerospace, defense, and unmanned electronics initiatives. Its light- and moisture-curing capabilities promote process efficiency and comprehensive coverage, while its MIL-I-46058C certification and NASA MAPTIS listing validate its suitability for high-reliability and space-rated applications.

This product ensures consistent protection for circuit assemblies where environmental exposure, mechanical stress, and vacuum compatibility are critical design considerations.