Ultra Motion specializes in precision-engineered electro-mechanical linear and rotary servo actuators, equipped with integrated brushless DC motor control systems and non-contact absolute position feedback.

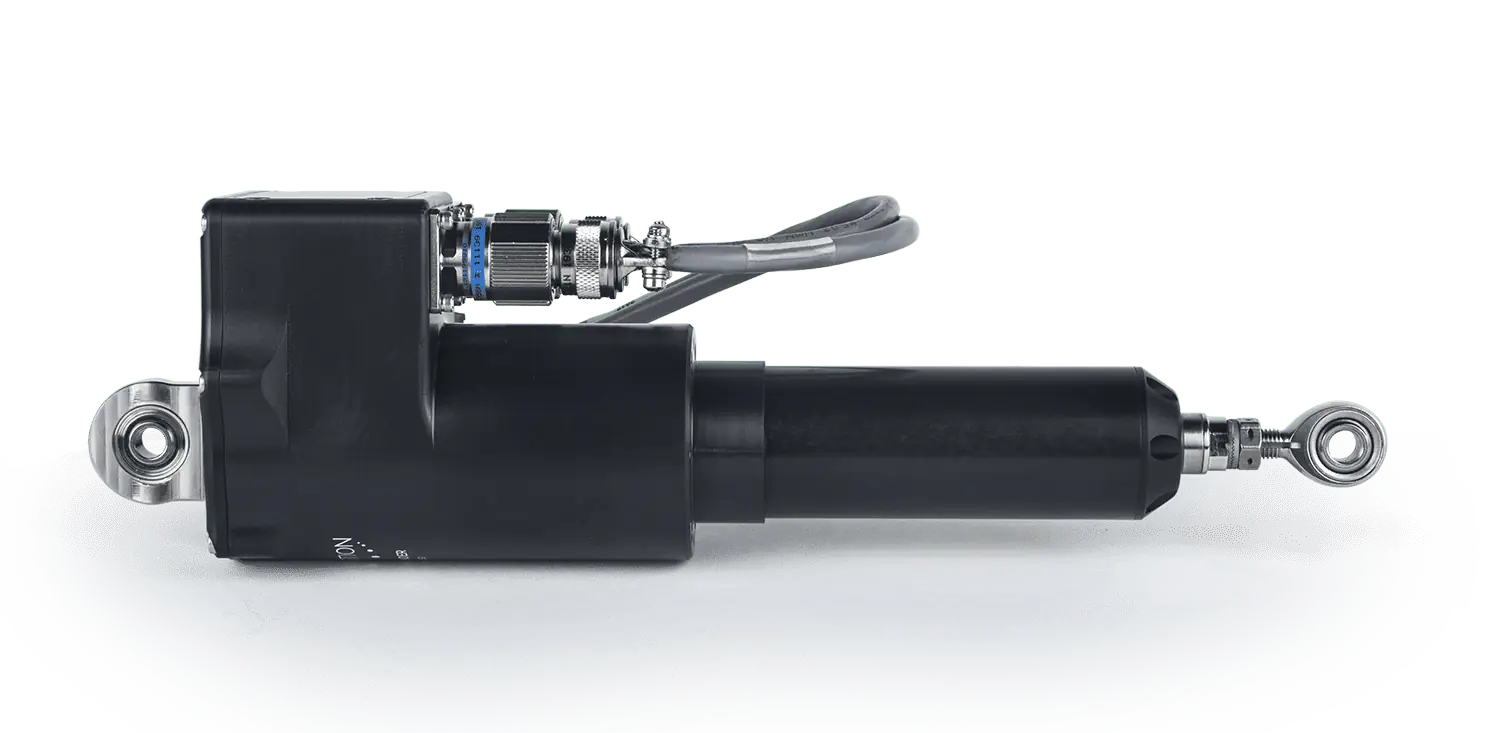

The company’s Servo Cylinder is a top-tier option for controlling UAV surfaces and serves as a reliable utility linear actuator, delivering outstanding performance and dependability.

Notably, the A-Series Servo Cylinder features a brushless DC motor along with contactless absolute position feedback, enhancing performance by reducing wear compared to conventional potentiometers and brushed DC alternatives.

Its integrated control electronics accommodate various interaction protocols, such as CAN 2.0B, RS-422/485 serial, RC PWM, and 4-20 mA in/out, ensuring seamless integration with diverse control systems.

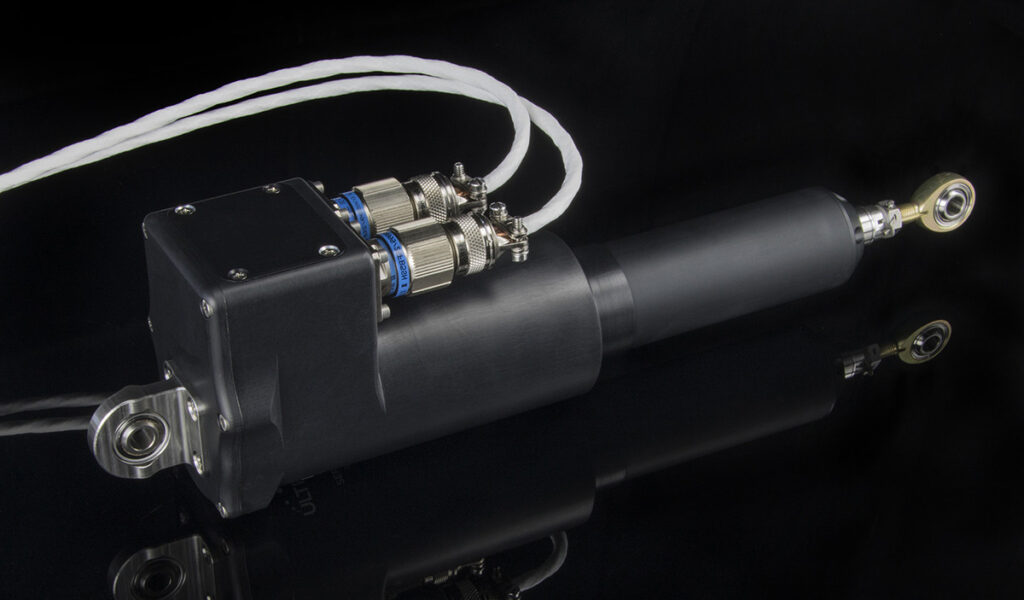

AM series Servo Cylinder

Engineered for challenging environments, the Ultra motion AM Series Servo Cylinder is rated IP65 for dynamic and IP67 for static ingress protection, making it suitable for extreme shock and vibration scenarios.

Military-grade D38999 connectors provide secure connections,while onboard sensors continuously monitor temperature,current,voltage,and humidity,ensuring the actuator’s health is consistently tracked.

Custom firmware for heating is available, allowing the controller to maintain a configurable temperature even in frigid conditions as low as -40°C.

The Servo Cylinder operates within a bus voltage range of 8 to 36 VDC, making it compatible with most UAV power systems and functional even at voltages exceeding 51 VDC.

It boasts impressive specifications,including force capabilities of up to 530 lbf,stroke lengths reaching 7.75 inches, and speeds of up to 14 in/s. These features enable high-bandwidth control exceeding 15 Hz, even for small positional adjustments.

The helically skewed BLDC motor design eliminates detent torque, allowing for smooth backdriving at low forces (~10 lbf) when unpowered or set to zero phase current. This innovation removes the need for bulky and expensive magnetic clutch assemblies, especially beneficial in optionally piloted vehicle (OPV) applications.

Transitioning from rotary to linear actuators in control surfaces yields significant advantages, including enhanced power density, improved control authority through higher resolution position control, reduced backlash, and savings in both cost and weight.

Aerospace Applications & Other Servo Solutions

Ultra Motion actuators have demonstrated their reliability in critical aerospace missions,including:

- Functioning as a vital component in the launch escape system of crewed spacecraft.

- Facilitating thrust vector control for orbital transfer vehicles, upper-stage rockets, and lunar lander engines.

- Powering experimental equipment aboard the International Space station.

The AM and L-Series servos from Ultra Motion can be customized for vacuum applications,providing dependable,off-the-shelf solutions tailored to the rigorous demands of the burgeoning new-space sector.

These cost-effective, space-ready components help lower the expenses associated with in-space missions without compromising on performance or reliability. Additionally, the R-Series is available for applications that require maximum power density, and fully customized actuator designs can be created to meet specific user requirements.