Specialty Coating Systems Inc. (SCS) highlights that the corrosion of electrical connections within printed circuit boards (PCBs) and similar devices poses notable safety risks, perhaps leading to severe failures in aerospace, automotive, or industrial machinery.

In healthcare settings, corrosion can disrupt the functionality of devices like pacemakers or introduce harmful substances into the bloodstream.PCBs are particularly vulnerable to electrolytic corrosion under certain conditions:

- Moisture or water can become trapped between electrical contact points.

- When voltage is applied, unintended electrolytic cells may form, leading to the breakdown of compounds and initiating corrosive reactions.

- Residues such as salt, dirt, oil, or chemicals trapped beneath a conformal coating can trigger corrosion.

- Corrosion often initiates beneath the conformal layer due to liquids or residues, and rapid temperature fluctuations can cause cracks in the coating, further exposing the surface to corrosion.

- Metals used in PCBs can form oxides or salts during operation, contributing to corrosion and performance degradation.

- Non-metallic materials like plastics or ceramics can also undergo chemical degradation, compromising mechanical integrity and functionality.

Given the compact nature of PCBs, identifying and predicting corrosion mechanisms can be challenging. Pitting and cracking can lead to significant damage to both external surfaces and internal components.The request of a conformal layer of Parylene (XY/poly-para-xylylene)—a non-toxic and non-critical material—can effectively mitigate corrosion risks.

advantages of Parylene Coatings

Parylene provides an ultra-thin, seamless, and pinhole-free protective layer with exceptional barrier properties against moisture, along with mechanical strength and electrical insulation. Unlike conventional wet coating methods—such as acrylic, epoxy, silicone, or urethane—that are applied through spraying, brushing, or dipping, Parylene is deposited via a chemical vapor deposition (CVD) process.

In the CVD process, a solid dimer of poly-para-xylylene is heated to a high temperature, transforming it into a vapor that penetrates the surfaces of components, forming a uniform coating both internally and externally. The Parylene film builds directly on the substrate one molecule at a time, eliminating the need for a curing step, which sets it apart from conventional liquid coatings.

In most applications,Parylene outperforms wet coatings,exhibiting excellent thermal stability,abrasion resistance,and chemical inertness,making it highly effective against corrosion.

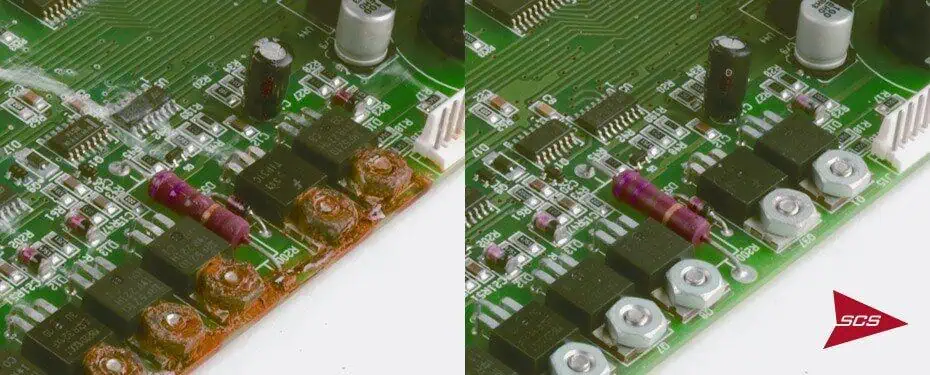

Though, Parylene does have its limitations. If the substrate is not adequately cleaned, adhesion might potentially be compromised, diminishing the coating’s protective properties. Contaminants such as oils, dust, process residues, or organic materials can lead to peeling and expose the surface. To ensure robust adhesion of XY to the substrate, all contaminants must be eliminated to prevent mechanical stress between the surface and the coating.

While Parylene coatings provide superior corrosion resistance, they often struggle to adhere to metal surfaces, which can be problematic for PCB applications. Manny PCBs incorporate gold components due to their excellent conductivity. Technologies like SCS AdProPlus® and AdProPoly® are specifically designed to enhance adhesion to challenging surfaces such as gold, titanium, stainless steel, chromium, solder masks, and various polymers. In medical implants, interactions with the body’s immune system can generate OH-dot radicals at the metal interface, leading to degradation that starts at the junction of the metal and Parylene layer.

Incorporating a silane layer, such as A-174 silane, at a thickness of 2 μm can significantly enhance both adhesion and corrosion resistance. A-174 chemically bonds with the surface,reinforcing the mechanical attachment of the XY layer. Silane can be applied through immersion, vapor-phase, or spray methods, creating a molecular bond with the surface.This treatment is effective for metal surfaces as well as elastomers, plastics, paper, and glass prior to CVD coating application.

Numerous studies have validated the effectiveness of treated Parylene in resisting corrosion:

- Plasma surface treatments have demonstrated a reduction in delamination of Parylene in medical implants. In one study, aluminum sheets coated with a 50 nm plasma polymer layer showed improved corrosion resistance and coating stability.

- A dual-layer coating system utilizing both A-174 silane and Parylene, with a total thickness of 2 μm, offers robust protection for medical-grade stainless steel in bodily fluids.

- Medical implants that receive A-174 silane treatment before Parylene application benefit from enhanced film continuity and inertness, providing resistance to corrosion induced by body fluids and reducing the risk of immune system reactions.

Interface engineering (IE) further optimizes the performance of Parylene C on cold-rolled steel (CRS). On smooth or non-porous surfaces, Parylene C may exhibit weak adhesion and limited corrosion protection. However, introducing an intermediate plasma polymer layer through IE fosters a stronger bond at the interface, enhancing overall corrosion resistance.

For optimal outcomes, corrosion protection should commence with a pre-CVD surface inspection to identify contaminants. If impurities are detected, they must be removed. Components such as connectors and electrical elements should be masked during the coating process.

Surfaces like metal, glass, paper, and plastic typically require pretreatment with adhesion promoters such as A-174 silane, AdProPoly, or AdProPlus to prevent delamination and minimize the risk of corrosion onset.

Read the original article >>