CRP Technology, a leader in professional 3D printing utilizing Windform composites, is gearing up for participation in two significant expos this September.

The company will be showcasing its innovations at the inaugural Space-comm Expo Scotland, scheduled for September 11-12, 2024, at the SEC glasgow, followed by the DroneX Expo on September 24-25 at ExCeL, London.

Spotlight on Space-Comm Expo Scotland

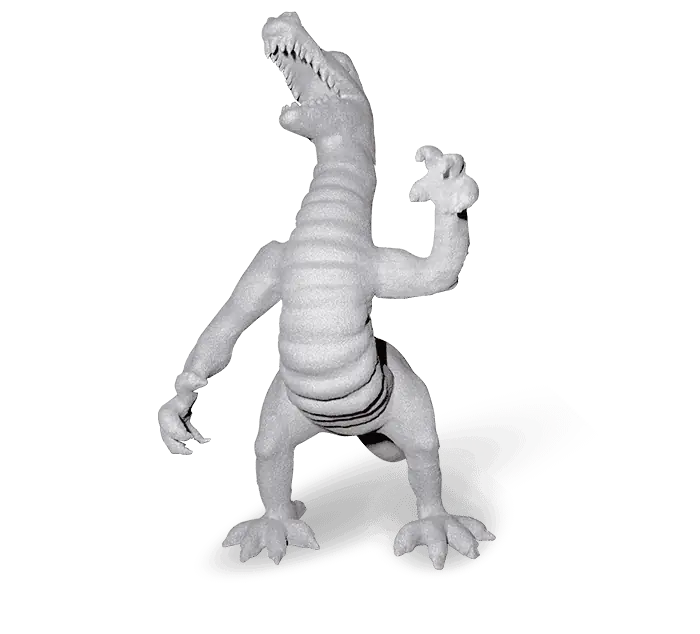

Following a successful appearance at the Space-comm Expo in Farnborough,CRP Technology is set to unveil its advanced solutions at this new venue. Attendees can find CRP at Booth F26, where the company will highlight its latest technological advancements.

Visitors to Booth F26 will have the chance to witness practical applications and achievements of windform manufacturing materials alongside laser sintering technology. The expert team from CRP will be available to discuss ongoing projects and how their services can enhance aerospace initiatives, providing valuable insights into the advantages and uses of their 3D printing capabilities with Windform.

Insights from the CEO

Franco Cevolini,CEO and CTO of CRP Technology,remarked,“Our advanced thermoplastic materials and 3D printing capabilities are revolutionizing the aerospace industry. Windform materials have successfully met the outgassing standards set by leading global space agencies, ensuring they fulfill the rigorous demands of space applications with unparalleled performance and reliability. We will showcase components ready for space missions, particularly in the small satellite and deployer sectors, which have played crucial roles in major space endeavors.”

Exploring Innovations at DroneX Trade Show & conference

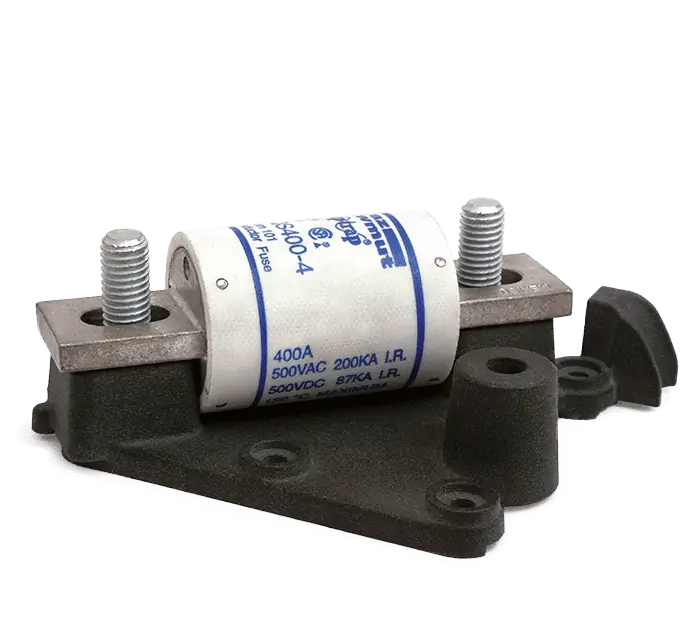

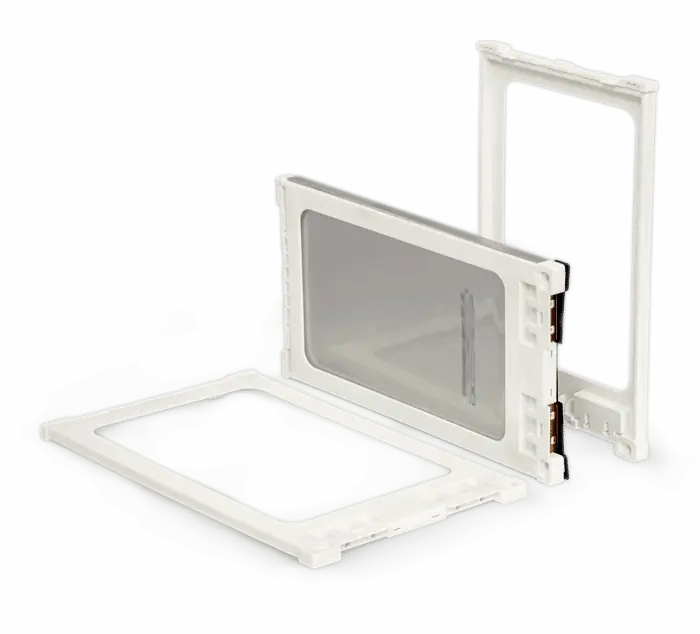

At DroneX, attendees visiting Booth B40 will have a unique prospect to discover the latest in 3D printed components crafted by CRP Technology using Windform composites and the selective Laser Sintering (SLS) technique, tailored specifically for the drone sector.

The company will present a variety of 3D printed parts that exemplify the remarkable properties of Windform composites, which are essential for the UAV industry. These include an extraordinary balance of lightweight design and strength,along with outstanding electrical insulation characteristics.

CRP Technology’s specialists will be present to discuss how integrating 3D printed parts made from Windform composites can transform your drone projects.