Frameless motors consist solely of the rotor and stator components,omitting an external casing,bearings,and shaft. This streamlined design facilitates seamless integration into the mechanical framework of the device it powers.Discover more >>

Alva Industries’ slotless frameless motors, enhanced by FiberPrinting™ technology, showcase exceptionally thin active components, making them ideal for embedded applications.Moreover, these slotless motors exhibit reduced sensitivity to radial misalignment between the rotor and stator, easing integration in various scenarios.

The advantages of slotless frameless motors include improved system performance, reduced maintenance needs, compact design, and heightened efficiency. However, the processes of mounting, installation, and integration present practical challenges that must be addressed.

This article delineates essential principles for the installation of frameless motors, detailing standard methods for mounting stators into housings and securing rotors onto shafts, along with general guidelines for handling, safety, and storage.

Essential Pre-Installation Factors

- Thermal Management: Ensure adequate cooling, as frameless slotless motors, like all motors, produce heat during operation.

- Electrical Compatibility: Confirm the motor’s electrical specifications align with the electronic controller’s requirements.

- Structural Integrity: Verify that the mechanical structure can support the motor’s weight, torque, and dynamic motion if the motor is not fixed in place.

Safety Measures

The rotors of frameless motors are equipped with powerful rare-earth magnets that generate strong magnetic fields.Individuals with active medical implants, such as pacemakers, should maintain a safe distance from these rotors.

The magnetic forces can attract ferromagnetic materials (like metals), potentially causing unexpected movements and collisions. It is advisable to keep all magnetic items at least three times the rotor’s diameter away from the motor.

Moreover,these magnetic fields can disrupt or damage electronic devices and storage media; therefore,it is crucial to keep rotors away from computers,monitors,and credit cards.

Handling and Storage Guidelines

Proper handling and storage of motor components are vital. Stators and rotors should remain in their original packaging until required. Handle stator assemblies with care to avoid damaging coil insulation and lead wires, which could result in electrical shorts.

Due to the strong magnetic forces, it is indeed crucial to handle the rotor assembly cautiously to prevent chipping or breaking magnets if the rotor is dropped or if magnetic objects come into contact with it (including other rotors).

Mounting the Stator into the Housing

- General Guidelines: Alva’s motors do not necessitate a soft-magnetic housing due to their inherent magnetic self-sufficiency. Aluminum housings are commonly utilized, although any suitable material can be selected. Metal surfaces should be designed to maintain a distance of 2-3 mm from the motor windings for insulation, with additional space allocated for motor leads.

- Grounding Requirements: For applications that require grounding, a ground stud can be integrated into the housing, establishing a standard grounding scheme. A ground stud is typically necessary only when the motor operates without isolation between the mains and the electronic speed controller.

- Stator Retention Techniques: Common mounting techniques include bonding, clamping, or shrink fitting, each with specific design considerations illustrated in accompanying figures.

Press-Fit Stator Retention

Creating an interference fit between the stator and housing by pressing the stator into place is not advisable for Alva’s motors.

If the motor is intended for operation across a wide range of environmental or operating temperatures, using an interference fit often restricts the choice of housing materials to those with thermal expansion coefficients (CTE) that align with the lamination material’s CTE.

Additionally, the pressing process may produce burrs that could damage windings and lead to electrical faults. Misalignment during pressing may also result in cracking or splitting of the lamination stack.

Heat Shrink-Fit Stator Retention

This method involves heating the housing before placing it over the stator. Though,similar issues with material compatibility and thermal expansion arise. Alva recommends using a light interference fit combined with adhesive bonding as a more reliable retention method.

Adhesive Bonded Stator Retention

Adhesive bonding is a widely accepted retention method, endorsed by Alva for numerous applications.

This technique allows for a variety of material choices for the housing. A groove of 0.2-0.3 mm in depth, covering 50-75% of the stator’s axial length, is recommended for optimal adhesion (see Fig. 2).

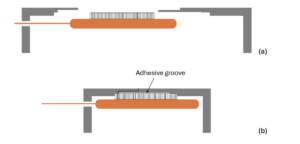

Fig. 2. Concept with adhesive groove.

For effective installation, it is advisable to use one of two recommended epoxies, with the process involving heating the housing to 100°C or higher. Once the required temperature is reached, promptly apply the adhesive into the groove in the heated housing and immediately insert the stator. cure the assembly at the epoxy’s specified cure temperature.

This method allows the housing bore to be designed as a line-to-line fit or with a light interference fit with the stator, depending on the selected housing material and its thermal expansion coefficient. once cured,the adhesive remains compressed at all other temperatures due to its expansion during the initial heated application.

If pre-heating the housing is not feasible before installing the stator, ensure the housing bore is designed to be at least 0.003-0.005 mm larger than the stator’s outer diameter, even under worst-case tolerances.

For adhesive selection, Alva can provide recommendations. However, 3M DP420 and Hysol E40HT are suggested as robust, general-purpose structural adhesives suitable for a variety of applications.

The concept involving overlapping end cups and the application of bonding adhesive is illustrated in fig. 3. It is essential to ensure proper alignment of the stator with the mounting points when utilizing this design.

Fig. 3. The concept with two overlapping end bells and adhesive groove: before assembly (a) and after assembly (b).

Axial Clamping Stator Retention

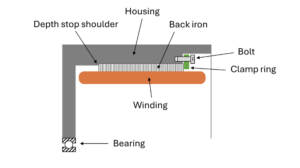

Axial clamping mechanisms are commonly employed to secure the stator. Alva’s frameless motor stators feature steel banking surfaces on both sides, allowing an axial clamp ring to apply pressure and hold the stator in position. This design simplifies maintenance and ensures reliable stator alignment.

An axial clamp should be designed to engage the top exposed banking surfaces of the stator, applying consistent axial pressure by being bolted into the housing. The axial clamp can be a full 360° ring or constructed from several “servo clamps” to secure the stator stack firmly in place.

One possible design is presented in Fig. 4, which allows for easy removal and maintenance access. This setup includes a locating shoulder for precise alignment of the stator, while a gap behind the clamp should be maintained to allow for compression on the stator. At least half of the stator back iron should be engaged with the axial clamp for optimal engagement.

Mounting bolts and washers can be utilized to secure the stator. Best engineering practices should be followed to determine the appropriate number and size of bolts for the axial clamp, ensuring they meet the torque requirements of the motor. Bolts should be tightened to the specified torque to guarantee reliable and stable assembly.

Fig. 4. Example concept with an axial clamp.

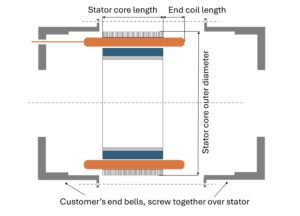

An choice to the axial clamp is mounting the stator assembly between two end bells, as illustrated in Fig. 5. End bells can be manufactured either by machining from a solid piece of stock or through a die-casting process.

In both scenarios, the end bells must provide a rigid, stable structure to support both the stator and rotor assembly.This design also facilitates easy removal or access for maintenance, making it practical for various applications.

Fig. 5. Example of stator assembly mounted between two end bells.

Bolt-In Stator Retention

Alva’s frameless motors typically do not utilize bolt retention due to the thinness of the lamination ring. Custom configurations can be arranged for specific applications.

Custom Integration Solutions

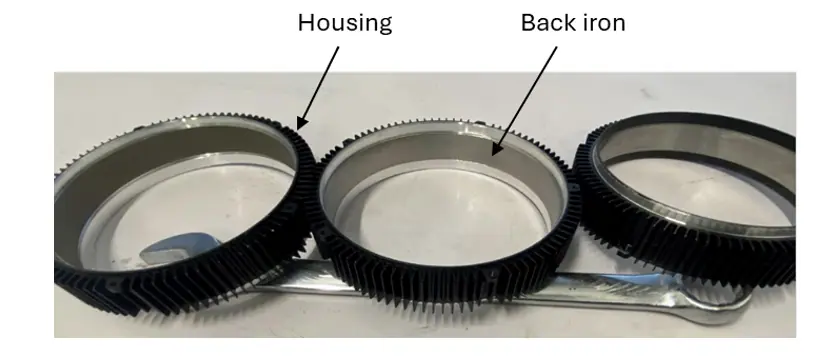

Custom integration solutions, were the back iron is installed into the customer’s housing with windings inserted in situ, can be arranged upon request (see Fig. 6).

Fig. 6. Molding in frame.

Rotor Installation Techniques

Alva motors employ Halbach magnet arrays on the rotor, negating the need for a magnetic carrying structure.

Mounting the rotor to the shaft can be accomplished through various methods, including press-fit, adhesive bonding, and axial clamping, each tailored to torque requirements and the rotor’s operational habitat.

Press-Fit Rotor Retention

One press-fit method secures the rotor to the carrying structure by creating an interference fit between serrations on the carrying structure and the rotor’s inner circumference. Typically, four serrations are evenly spaced around the outer diameter of the carrying structure, with each serration extending at least three-quarters of the rotor’s length. Tapered serrations may also be utilized.

The rotor’s inner diameter should align with the carrying structure’s outer diameter, maintaining a clearance range between 0.005 mm and 0.05 mm.

an alternative press-fit approach employs a tolerance ring positioned within a specialized feature on the carrying structure.

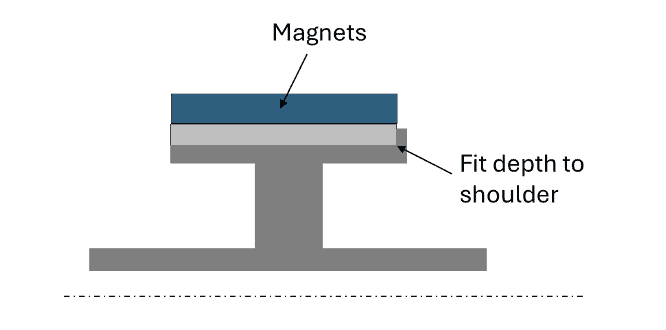

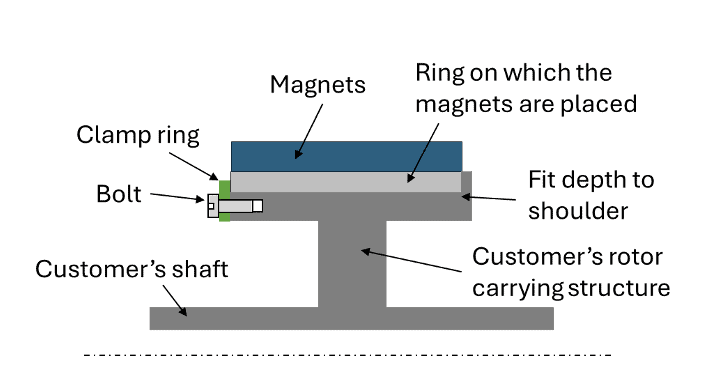

During the press operation,apply pressure solely to the carrying ring of the rotor—avoiding direct contact with the magnets. A shoulder element on the carrying structure can ensure correct rotor positioning (see Fig.7).

Fig.7. Illustration of press-fit and shrink-fit concepts.

Heat Shrink-Fit Rotor Retention

This method involves cooling the carrying structure to create a clearance fit, followed by positioning the rotor onto the structure. Similar to press-fit, this method is based on designing an interference fit between the rotor and the carrying structure.However, heating the rotor is avoided to prevent demagnetization of the magnets.

Adhesive Bonding for Rotor Retention

Using high-strength adhesives, the rotor is bonded to the carrying structure, with adhesive grooves providing additional support (see Fig. 8). Material compatibility should be assessed to account for temperature and thermal expansion differences.

This method secures the rotor to the carrying structure using a high-strength retaining compound, such as 3M DP420, Hysol/Loctite E40HT, Loctite 648, or other epoxy-based structural adhesives.

Consult adhesive manufacturers to select the appropriate retaining compound for the specific application. An adhesive groove should be designed on the rotor mating part, typically with a depth of 0.2–0.3 mm. The groove length is generally 50% to 75% of the rotor’s axial length, though various groove configurations are possible (see Fig. 8).

Fig. 8. Concepts employing adhesive bonding.

Adhesive bonding accommodates a wide range of materials for the mating structure, but differences in thermal expansion coefficients and operating temperatures should be carefully considered.

Axial Clamping for Rotor Retention

This method secures the rotor using a clamp ring that exerts force to hold it in place. To prevent loosening, a lock washer or bonding agent might potentially be utilized. The number of screws needed will vary based on the rotor’s size, torque requirements, and the specific application.

It is indeed essential to avoid clamping directly on the magnet material,as it is quite brittle. Clamping should be applied solely to the magnet-carrying ring,as illustrated in Fig. 9.

Fig. 9. Axial clamping concept.

bolt-In and Key-Way Rotor Retention

While bolt-in retention is feasible for customized configurations, alva’s standard rings do not include bolt holes. Keyways are generally not recommended due to their complexity and over-design for most torque applications; though,customers can contact Alva to order special custom ring configurations if desired.

fig. 10. Bolt–in rotor retention concept.

Custom Solutions

Alva provides solutions for direct magnet mounting onto custom hubs, streamlining assemblies and minimizing components.

Key Assembly Considerations

When assembling the stator and rotor, several practical aspects must be taken into account:

Magnetic Forces: The magnetic attraction between the rotor and stator can be significant, necessitating careful handling during assembly.To protect both the magnets and the stator windings from potential damage, a thin non-magnetic sleeve (or an equivalent protective device) should be wrapped around the rotor during installation. After successfully installing the rotor within the stator, this sleeve can be removed.

Alignment: Accurate alignment of the rotor and stator is crucial to prevent imbalances that could affect performance.

free Rotation: Ensure that the rotor can rotate freely without any contact with the stator or other components.

Post-Installation Checks:

- Temperature Monitoring: During initial operation, monitor the temperatures of both the motor and gearbox to ensure adequate cooling is maintained.

- Testing: Power on the motor and conduct initial tests to verify proper operation and alignment between the rotor and stator.

- Vibration Assessment: monitor for any unusual vibrations,which may indicate misalignment or other issues that require attention.

Read the original article >>