This article explores the concept of industry 5.0, a transformative phase in industrial evolution, as presented by Knight Optical, emphasizing enhanced collaboration between humans and robots.

Additionally, Knight Optical highlights how its precision optics empower these collaborative robots to perceive and interact with their surroundings, enabling them to execute their designated tasks effectively.

At present, we are experiencing the advantages of Industry 4.0, characterized by the introduction of innovative technologies and cyber-physical systems that are revolutionizing manufacturing processes globally.

As we transition to Industry 5.0, we anticipate unprecedented levels of collaboration, with robots and humans working closely together.

Knight Optical, a premier provider of custom optical components for a wide array of scientific and technological applications, including robotics, invites you to envision the future of Industry 5.0.

Understanding Industry 5.0

Frequently enough referred to as the Fifth Industrial Revolution, Industry 5.0 represents a significant leap in industrial progress. While some companies are still adapting to Industry 4.0, others are already setting their sights on this next evolution.

This forthcoming phase aims to enhance the well-being of workers by integrating human creativity and empowerment with flexible, adaptable technologies. This synergy fosters innovation while leveraging the efficiency and reliability of robotic systems.

Transformations in the Workplace

Today’s manufacturing environments are increasingly driven by digital technologies, and the shift towards Industry 5.0 will see humans and robots collaborating on tasks that were once performed solely by people.

The close interaction between humans and robots is pivotal to this evolution. These collaborative robots, or cobots, are frequently enough more cost-effective than conventional robotic systems.

As Industry 5.0 unfolds, workplaces worldwide are poised to integrate advanced technologies such as artificial intelligence (AI), the Internet of Things (IoT), and big data, allowing for seamless human-robot collaboration. Many forward-thinking companies have already begun incorporating these technologies into their production lines, enhancing efficiency and productivity.

Cobots: The Core of Industry 5.0

The essence of Industry 5.0 lies in merging high-performance robotics and automation with human involvement. Cobots are at the forefront of this integration. Historically, many robotic systems were considered hazardous to work alongside, frequently enough confined within safety barriers to protect human workers.

Today, cobots operate alongside humans, thanks to innovations from companies like Universal robots, which offers a range of devices, including robotic arms equipped with grippers and soft-touch tools.

Exploring Cobots Further

Cobots are utilized across various sectors, from manufacturing to food processing, and their implementation is yielding significant benefits. They enhance precision, minimize waste, and save time, all while being more compact and user-amiable compared to traditional robots that require isolation from human workers.

A notable player in this arena is FANUC, a Japanese robotics firm that has successfully integrated cobots into existing production lines globally. For instance, in Benteler International’s smart factory in Germany, the FANUC CR-35iA operates safely at high speeds (750 mm/s) to load parts without the need for safety cages.

The Role of Artificial Intelligence (AI)

AI plays a crucial role in processing data collected by sensors, organizing and contextualizing this data. This data is then utilized by machines, robots, and cobots to make informed decisions and execute their tasks effectively.

Given the past concerns regarding safety in human-robot interactions, AI is vital for ensuring the safe operation of cobots. As noted by CPO magazine, “Industry 5.0 requires reliable data,” and users must trust that the information guiding these systems is accurate and dependable.

The Importance of Optical Components

Beyond software and cloud solutions, optical components are integral to the hardware used in this field.In the context of cobots, these optics are embedded within the systems themselves.

Optics are essential for tasks requiring high visual acuity, such as precise measurements, accurate welding, and efficient picking and packing. High-quality optics enable these systems to perceive and interact with their environment, ensuring they fulfill their programmed roles effectively.

Moreover, superior optical clarity is crucial for the optimal performance of cobots. Ultra-precision optics facilitate seamless task execution, helping companies meet production goals and enhance overall productivity.

Our range of High-Quality Optics

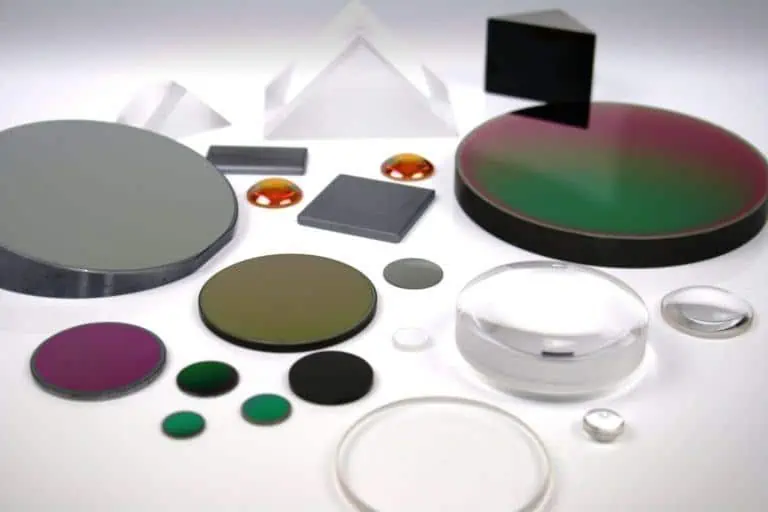

At Knight Optical, we offer an extensive selection of premium, ultra-high-precision optics tailored for cobots. Whether you need optical components for advanced sensors that help cobots detect nearby objects, protective windows to shield internal components from dust, or IR optics for thermal imaging applications, we have a comprehensive array of options available.

with over 3,000 stock optics and custom designs, we cater to every cobot submission. additionally, we provide various optical coatings to ensure your application performs optimally in any environment.

FOOTNOTES

1

https://www.forbes.com/sites/jeroenkraaijenbrink/2022/05/24/what-is-industry-50-and-how-it-will-radically-change-your-business-strategy/

2

https://www.cpomagazine.com/cyber-security/why-industry-5-0-needs-trusted-data/