The Specialty Coating Systems (SCS) has developed the innovative PrecisionCoat VI, a highly adaptable and fully programmable system for selective conformal coating and dispensing, designed to enhance automated material applications.

beyond its role in coating drone electronics, the PrecisionCoat employs advanced multi-valve technology for applying underfill materials, while its potting platform streamlines the potting process, substantially boosting production precision and efficiency. Both underfill and potting techniques are crucial in electronics manufacturing, each with unique application methods.

Understanding Underfill Applications

Underfill is a composite material made from epoxy polymers, enriched with fillers and additives such as flow agents, adhesion enhancers, and colorants.

This material is vital in industries like consumer electronics, semiconductor packaging, automotive, mobile technology, and artificial intelligence, particularly in applications that demand enhanced performance and compact designs.

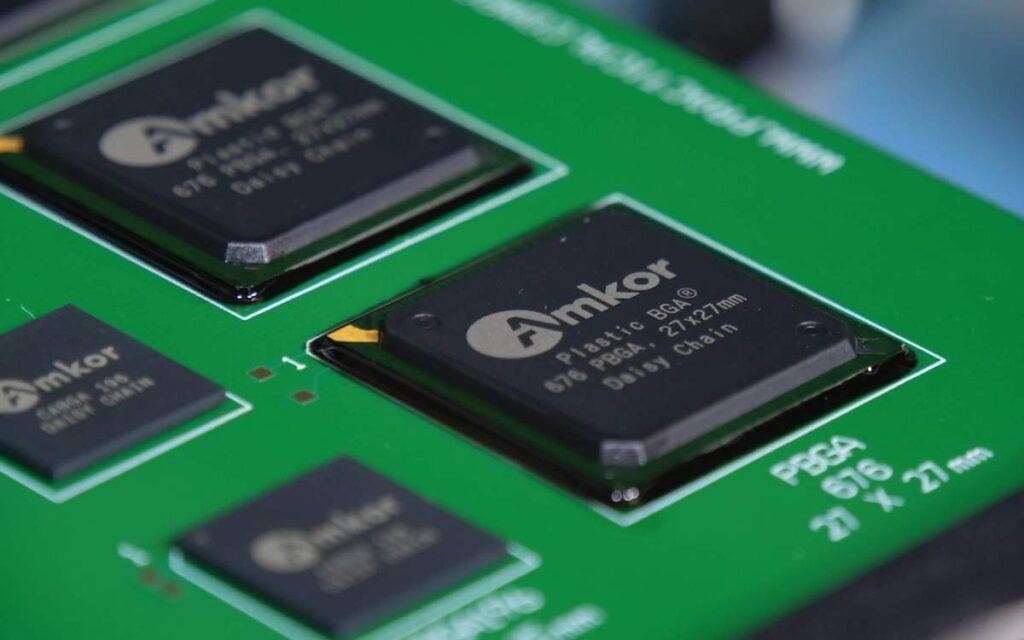

Underfill acts as a protective barrier for electronic devices against mechanical shocks and thermal fluctuations, thereby prolonging their operational lifespan. While it is primarily utilized in flip-chip devices, such as handheld gadgets that undergo rigorous drop tests, it is also applicable to ball-grid arrays (BGAs). The PrecisionCoat, equipped with the SCS tower jet valve, can effectively dispense underfill along the edges or corners of BGAs or similar devices.

Once applied, the chip and printed circuit board are heated to a specific temperature, generally ranging from 125°C to 165°C, depending on the manufacturer’s specifications. At this temperature, the underfill transitions to a liquid state, allowing it to flow beneath the chip.

This process establishes a robust mechanical bond between the chip and the printed circuit board, protecting solder joints from mechanical stress and facilitating heat dissipation. However,the strength of this bond can complicate rework efforts.

exploring Potting Applications

potting involves using one- or two-part materials to shield components from environmental and mechanical hazards. Common potting materials include epoxies, silicones, and polyurethanes, which serve as both the base and activator, initiating the transformation from liquid to solid.

This technique provides electrical insulation, thermal stability, and chemical resistance, making it particularly suitable for high-voltage applications. Potting is extensively used in various electronic devices, including power supplies, switches, ignition coils, electronic modules, motors, connectors, sensors, cable harness assemblies, capacitors, and transformers.

To cater to diverse volumes and material types, a pumping system can be utilized for accurate measurement and dispensing. This can be executed in single or multiple stages to minimize voids and ensure consistent filling of the device or enclosure. For two-part materials, precise metering and mixing are essential for effective curing.

The PrecisionCoat potting platform can be customized with one or multiple dispensing heads for either one-part or two-part materials.Various dispensing methods, such as bottom filling, multi-stage fills, or multi-shot applications, can be employed to minimize void formation within the cavity.

Potting offers reliable, long-lasting protection against environmental factors. Though, it does introduce additional weight, thickness, and complexity to electronic assemblies, as a housing is necessary to contain the potting material. Additionally, two-part compounds may have specific processing requirements, and potting can pose challenges for inspection or rework.

Read the original article >>