Alva Industries AS has unveiled an innovative production technique called FiberPrinting™, designed to considerably improve the efficiency of slotless and ironless motors and generators. Hear’s a brief overview of this groundbreaking process.

Understanding the FiberPrinting™ Method: A three-step Approach

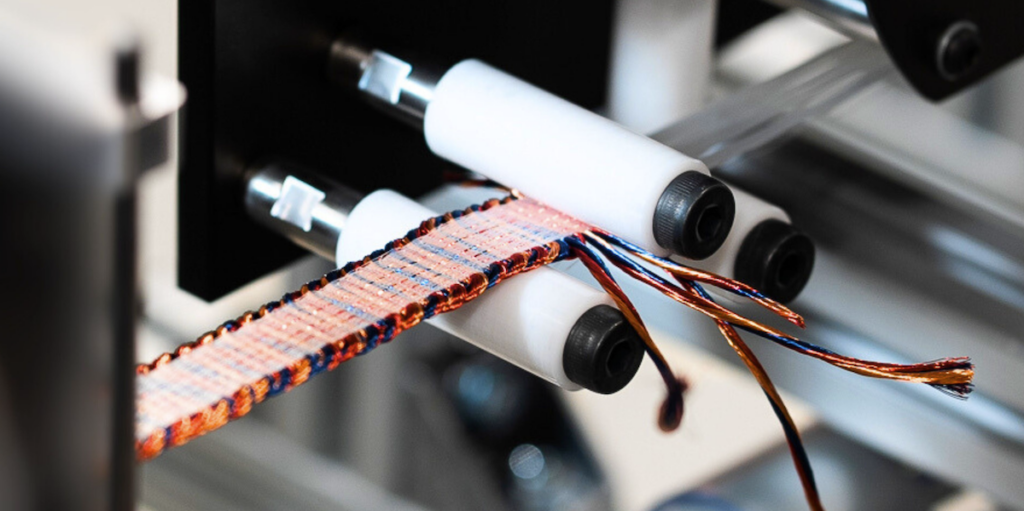

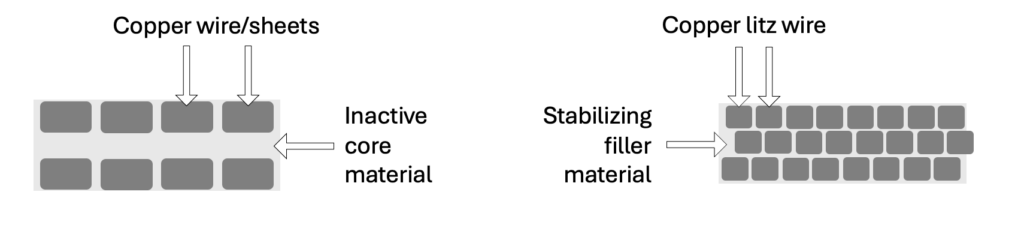

Fig.1. Illustration from Alva’s patent US11646645B2 [1].

Step 1: Printing: The process begins with the integration of copper wires and structural fibers into a flat, flexible composite material (Fig.1). These copper wires will ultimately serve as the electrical windings in the finished motor or generator.

- Step 2: Shaping: The composite material is then molded into a cylindrical form and placed within a mold.A stabilizing filler,usually epoxy,is introduced at this stage.

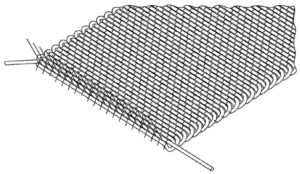

- Step 3: Curing: The final step involves curing the material along with the stabilizer before demolding (Fig. 2). The result is a self-supporting cylindrical component featuring integrated copper windings, which generates a rotating magnetic field when supplied with AC power.

Fig.2.Microscopic view of alva’s slotless stator, showcasing the consolidated litz wire strands, filler material, and stator laminations.

Notable Benefits of FiberPrinting™

Enhanced Copper Fill Factor and Reduced Winding thickness

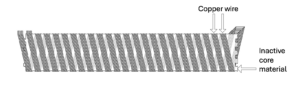

To achieve minimal copper winding losses,it is crucial to have a significant cross-sectional area of copper conductors to ensure low electrical resistance.Ideally, this area should be fully occupied by copper, reaching a 100% Copper Fill Factor (CFF).Tho, insulation requirements and manufacturing inconsistencies frequently enough lead to a lower CFF. A reduced CFF results in larger winding areas, which in turn necessitates thicker stator designs, heavier motors, and increased costs for permanent magnet materials.

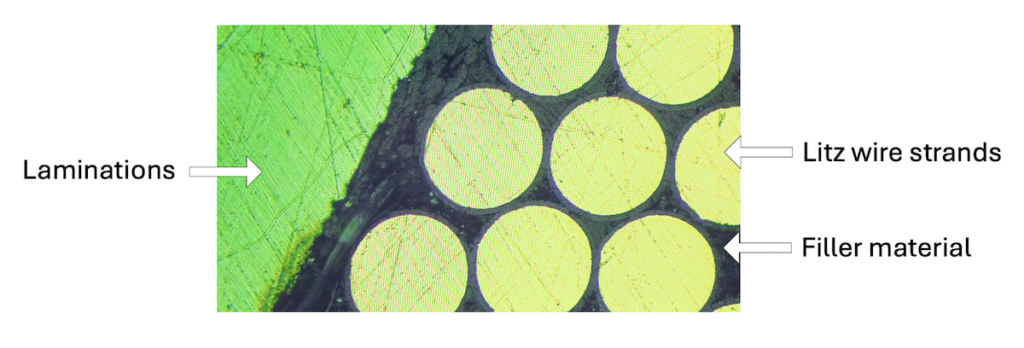

Fig.3. Illustration from a competing ironless motor manufacturer’s patent US9425664B2[2].

Conventional techniques typically involve wrapping copper coils around a plastic strip or layering precision-etched copper sheets with insulating materials, both of which diminish the CFF and occupy valuable space that could or else be filled with copper.

Fig.4.Cross-sectional comparison of an ironless winding: traditional (left) versus FiberPrinted (right).

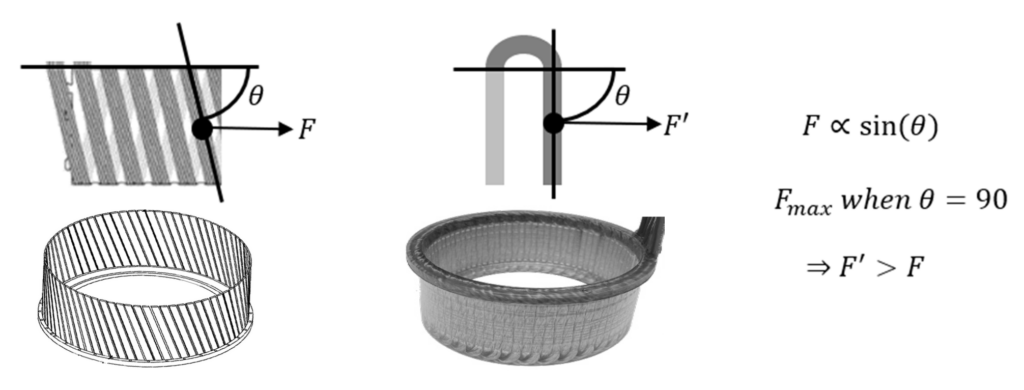

Optimal Winding Configuration

Traditional manufacturing methods require maintaining an angle on copper windings to conform to the stator surface, which can hinder efficiency. In contrast, FiberPrinting™ enables completely straight windings, thereby enhancing performance by maximizing the force generated by the coils in interaction with rotor magnets.

Fig.5. Comparison of an ironless stator from a competitor (left) and a FiberPrinted stator from Alva (right).

Efficiency in Production and Adaptability

Alva’s FiberPrinting™ method streamlines the labor-intensive processes typically associated with stator production, which is frequently enough the most intricate and costly aspect of electric motor or generator manufacturing. The automation of each phase facilitates mass production with minimal manual intervention, positioning FiberPrinting™ as a pioneering solution for large-scale ironless machine fabrication.

This process offers remarkable flexibility, similar to 3D printing, allowing for the creation of various winding sizes, shapes, and electrical characteristics without the need for retooling. Adjusting the axial length, diameter, or electrical specifications of the stator component is as straightforward as modifying the composite mat’s production parameters.

A Timely Advancement

Alva’s innovation is in sync with the latest developments in power electronics and battery technology, which are steering the industry towards lighter, more compact, and energy-efficient solutions. This advancement also renders ironless and slotless machines more economically viable, expediting the shift towards sustainable electric technologies.

For further details, read the original article or visit the alva Industries website.