United Electronic Industries (UEI) offers comprehensive hardware and simulation solutions that enhance the verification and validation (V&V) processes for unmanned aerial vehicles (UAVs), unmanned aircraft systems (UAS), and autonomous ground vehicles (AGVs).

UEI’s systems are extensively utilized in the aerospace,defense,and robotics industries,promoting model-based design (MBD),hardware-in-the-loop (HIL) testing,and the development of embedded systems.

As the sophistication and capabilities of unmanned technologies grow, customary development cycles are increasingly challenged. While the conventional V&V process—comprising testing, inspection, analysis, and presentation—remains vital, its late-stage application can led to significant delays in deployment.

To counter this, an integrated strategy that employs early-stage design Validation and Verification alongside Model-Based Design is emerging as a game changer. This holistic approach not only accelerates development timelines but also boosts system reliability and performance.

Understanding Design V&V in Unmanned Systems

Design Validation and Verification are critical in confirming that systems meet both operational goals and technical specifications.

Verification focuses on whether the system has been constructed correctly, ensuring compliance with design requirements.

Validation, on the other hand, assesses whether the correct system has been developed, confirming it aligns with user needs and mission objectives.

Model-Based Design: Bridging Concept and Implementation

Model-Based Design enhances efficiency by enabling development teams to simulate, analyze, and verify systems in a virtual habitat prior to physical execution. The primary benefits include:

- System Simulation: Assess performance across various conditions, including mission scenarios, environmental factors, and sensor degradation.

- Continuous Verification: Automate testing throughout the development phase to ensure ongoing compliance.

- Code Generation: Directly convert validated algorithms into embedded code, minimizing manual coding errors and expediting implementation.

- Hardware-in-the-Loop (HIL) Testing: Integrate simulated environments with actual hardware to evaluate real-time controller performance.

Such as, UAV developers can utilize tools like MATLAB/Simulink to simulate control logic, sensor integration, and navigation systems, allowing them to identify potential integration challenges early in the design phase.

Integrating V&V with MBD for Enhanced Outcomes

The combination of early V&V practices with MBD yields significant advantages:

- Accelerated Iteration Cycles: design changes can be swiftly validated through simulations.

- Scalable Testing: Facilitates testing for intricate systems, including multi-agent UAV operations.

- Failure Mode and Effects Analysis (FMEA): Safely simulates fault conditions for thorough testing.

- Streamlined Documentation: Automatically connects requirements, models, and test outcomes to ensure compliance with standards like MIL-STD.

This integration empowers developers to instill greater confidence in their systems, which is essential for unmanned platforms operating in critical mission scenarios.

UEI’s Offerings for Unmanned System Development

UEI provides a range of capabilities to bolster V&V and MBD efforts in UAV, UAS, and AGV applications:

- Hardware-in-the-Loop (HIL): Real-time simulation platforms facilitate embedded system testing with physical inputs and outputs.

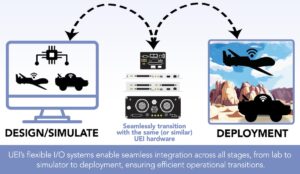

- Flexible I/O Integration: Features over 90 I/O modules that support CAN, ARINC-429, MIL-STD-1553, and also analog and digital signals.

- Embedded Systems Development: Controllers compatible with Linux, VxWorks, and real-time operating systems, supporting programming in C/C++, Python, and Simulink.

- Avionics and Automotive Protocol Support: Guarantees interoperability with aerospace and automotive communication standards.

- System-Integration-Lab (SIL) Testing: Enables virtual test execution using tools like LabVIEW, Simulink, or VISTAS (ED-247), along with hardware for integrated fault insertion.

- Longevity and Support: Platforms are designed for a 10-year availability guarantee and robust construction for lifecycle stability.

Incorporating UEI platforms into development workflows allows for quicker test setups, early fault identification, and comprehensive system-level validation without the need for full-scale prototypes.

Final Thoughts

As the demand for high-performance unmanned systems escalates, the need for accelerated V&V and virtual prototyping becomes paramount. utilizing early validation in conjunction with Model-Based Design facilitates faster, safer deployments while minimizing development costs.

United Electronic Industries champions this approach with scalable, versatile platforms that enhance simulation, integration, and embedded system testing. These tools empower developers to meet the evolving technical and operational demands in UAV, UAS, and AGV projects.