Deep Trekker has published a comprehensive guide on executing effective Underwater inspection In-Lieu of Drydocking (UWILD), addressing essential topics such as an inspection checklist, the significance of UWILD certification, and more.

Underwater Inspection in Lieu of Dry-Docking (UWILD) is increasingly recognized as a safer and more efficient method compared to customary dry-docking inspections for marine vessels. This process focuses on examining the submerged sections of a vessel.

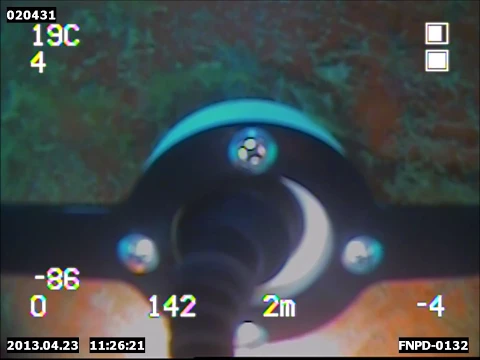

While thickness testing isn’t mandatory for every UWILD inspection, surveyors often request this data if they identify any areas of concern. The accompanying video illustrates how Deep Trekker’s DTG3, equipped with a thickness gauge, conducts these critical measurements.

The versatile design of Deep Trekker’s ROVs enables users to easily incorporate additional tools to enhance their inspections. Sonar capabilities deliver clear visuals for precise evaluations, even in murky waters. By integrating the Cygnus thickness gauge, operators can assess the hull and compartment thickness to ensure structural soundness. Additionally, the laser scaler is invaluable for estimating the dimensions of cracks, dents, or other defects.

Deep trekker’s article on UWILD best Practices includes:

- Understanding Underwater Inspection in Lieu of Dry-Docking

- The significance of UWILD Certification

- HIMP Program & ABS Certification

- Comprehensive Inspection Checklist

- Benefits of UWILD Inspections

- Utilizing ROVs for Underwater Inspections

Explore the complete article on Deep Trekker’s website >>