Innovative Rotor Solutions for the Skyspotter 150 UAV

Mejzlik Propellers has proudly announced its successful production of rotors for the Skyspotter 150, an autonomous helicopter UAV developed by LIAZ a.s. With extensive expertise in crafting large and custom-designed rotors, Mejzlik has previously tackled meaningful projects, including a 6-meter diameter propeller for a wind turbine.

Advanced Manufacturing Techniques

Utilizing the latest specifications for the UAV’s main and tail rotors, Mejzlik’s skilled technical team leveraged decades of experience in carbon fiber blade production to create a complete and enhanced solution. The helicopter features a twin-bladed main rotor with a diameter of around 3.2 meters, a size achievable with Mejzlik’s standard tooling and layering techniques. However, the team had to account for unique auto-rotation characteristics typically associated with UAV propellers.

Prototyping and Testing

After multiple iterations of prototyping, the team devised an internal structure incorporating a polyurethane core. the resulting propellers were not only lighter but also more robust than the initial designs. Following rigorous testing on the Skyspotter 150, LIAZ a.s. provided outstanding feedback regarding the new rotor design.

Custom Solutions for the UAV Market

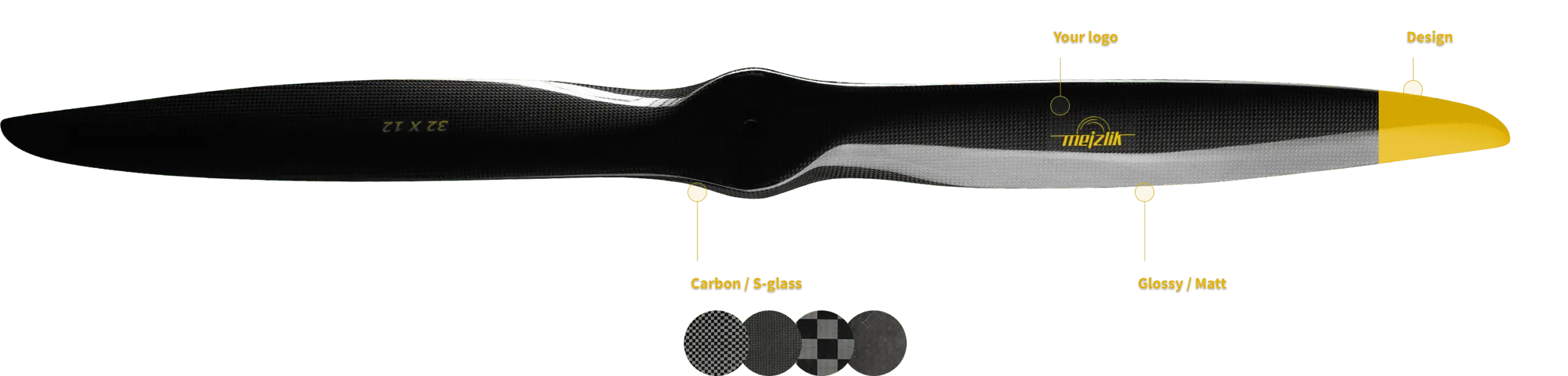

With a rich history of supplying propellers to prominent civil and military UAV manufacturers, Mejzlik is exceptionally well-suited to meet the demands of the unmanned helicopter sector. All production processes are conducted in-house,enabling the company to offer flexible customization options for internal structures,external blade designs,and testing protocols,while ensuring a high standard of quality.

Tailored Designs and Future Innovations

mejzlik is capable of producing UAV helicopter blades based on a client’s 3D model or can collaborate with their partner engineering firm to create new designs. The propellers are engineered using advanced mathematical models grounded in Blade Element Momentum and Vortex theory. Currently, the company is also developing innovative software aimed at simulating rotor noise and optimizing performance.

Client Testimonials

Libor Horáček from LIAZ a.s. remarked, “The Mejzlik team has been instrumental in producing our main and tail rotors. They respond promptly to our needs that arise during testing phases. we are thrilled to have found a partner with such extensive experience in carbon fiber blades, which allows them to provide valuable guidance.”