WilliamsRDM stands out as a premier innovator and producer of specialized support equipment and interconnect solutions tailored for unmanned aerial vehicles (uavs).

In its ongoing collaboration, UST is showcasing WilliamsRDM’s distinctive offerings and expertise through a dedicated supplier profile. This highlights the company’s extensive product range,its proficiency in delivering customized build-to-spec projects,and its capacity to assist UAV original equipment manufacturers (OEMs) and developers,regardless of project scale.

WilliamsRDM has established partnerships with top defense contractors,including Boeing,Northrop Grumman,Lockheed Martin,BAE Systems,Harris,and Raytheon,as well as with various branches of the United States Government.

Continue reading to learn more:

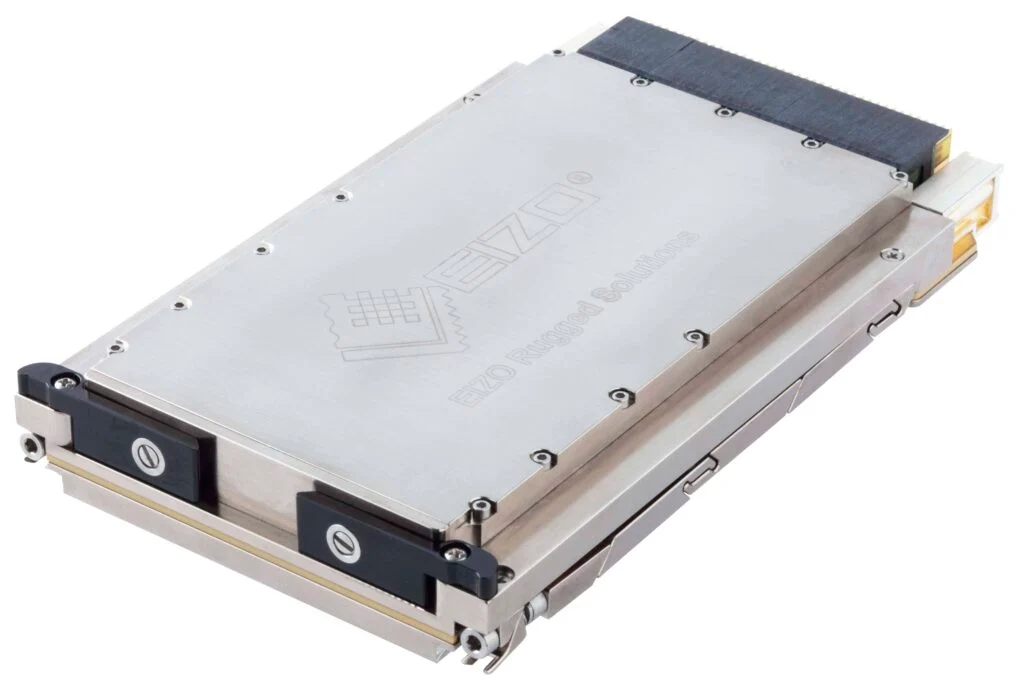

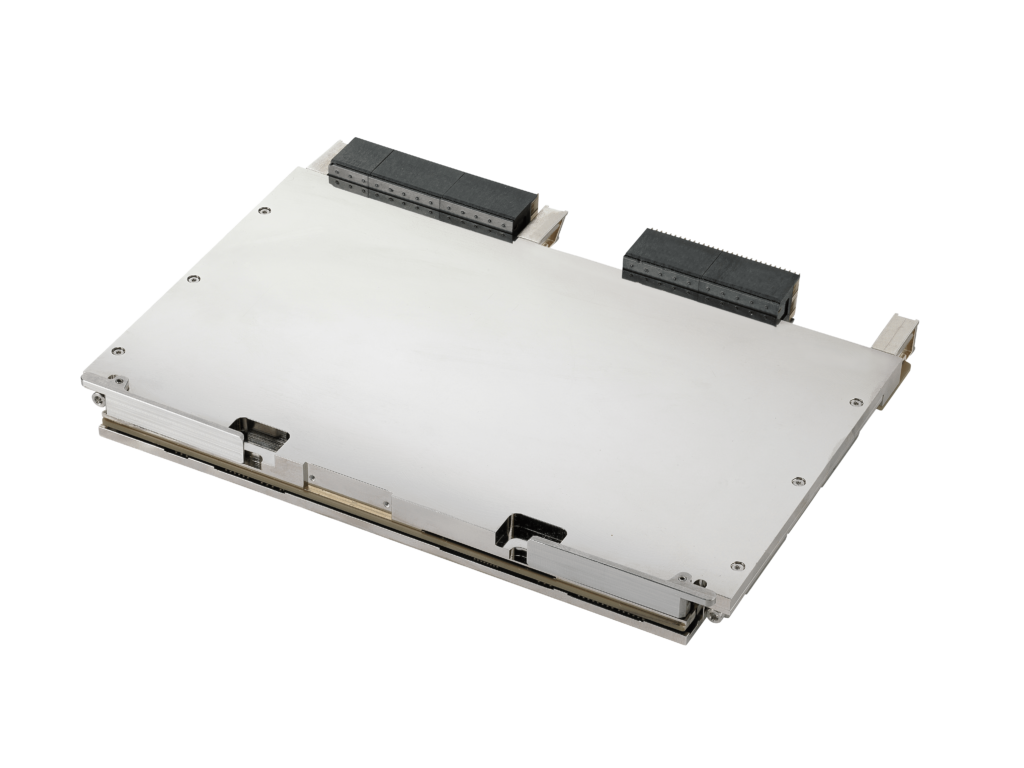

With advanced machining, fabrication, and assembly capabilities, WilliamsRDM is equipped to address the specific needs of UAV OEMs. This enables the production of high-precision components and subsystems suitable for a diverse range of platforms.The company operates in a near-clean-room surroundings, staffed by seasoned professionals and supported by Six Sigma methodologies and ISO and AS certifications, ensuring top-tier results regardless of project complexity or volume.

The in-house machining facilities boast cutting-edge equipment, including 5-axis and Swiss capability machines. Offline simulation techniques are employed to enhance efficiency and shorten project timelines. The skilled workforce adheres to ISO 9001 and AS 9100 quality management standards, ensuring superior accuracy from design to production and expedited turnaround times.

WilliamsRDM excels in developing cable and wiring solutions designed to endure the demanding conditions faced by UAVs and unmanned systems. Their rugged, ATE-tested, and flightline-qualified cables can withstand 75 lbs of tensile strength per cable leg and are rigorously tested across a temperature spectrum of -54 to +74 degrees Celsius.

These cables can be customized with various adapters and interconnect solutions to meet specific mission requirements, and can be designed to be either EMI-shielded or non-shielded.

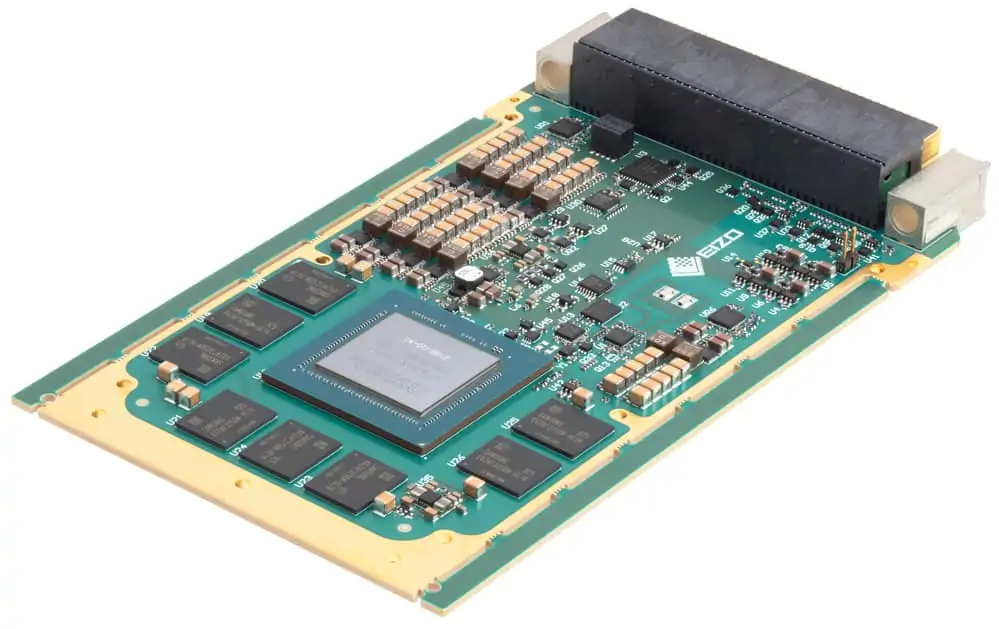

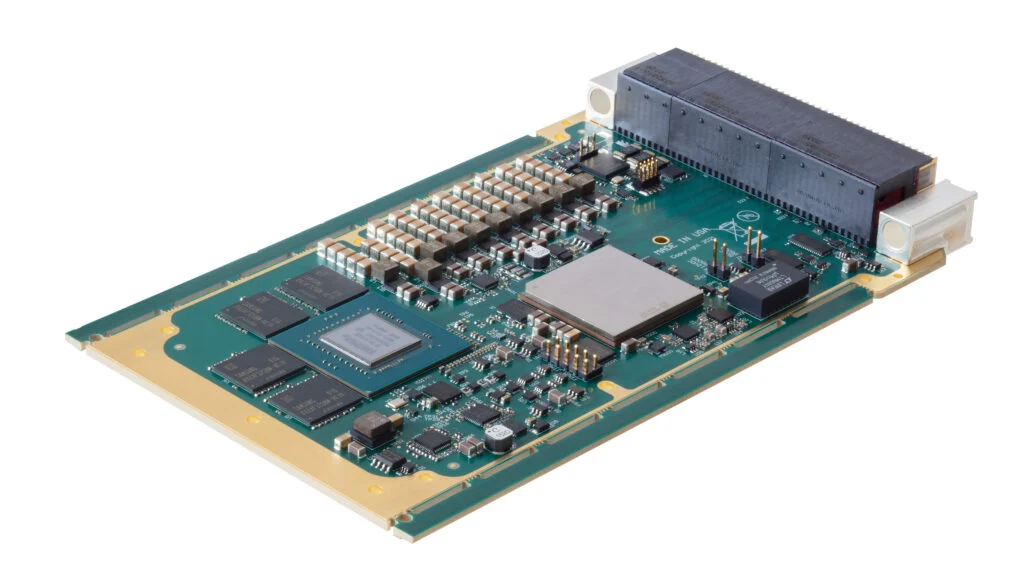

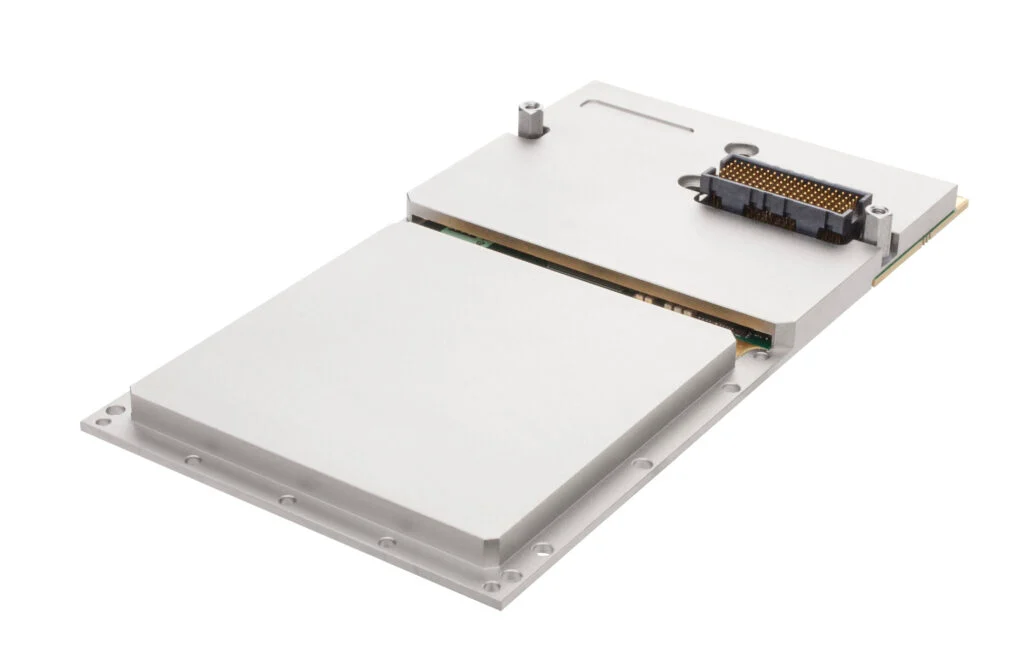

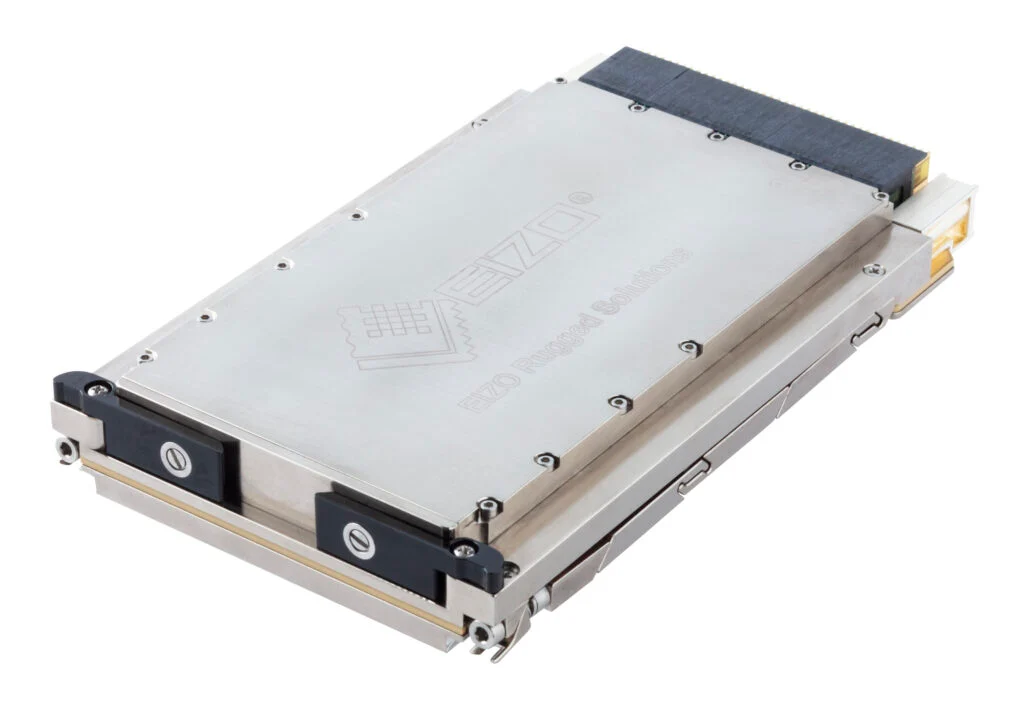

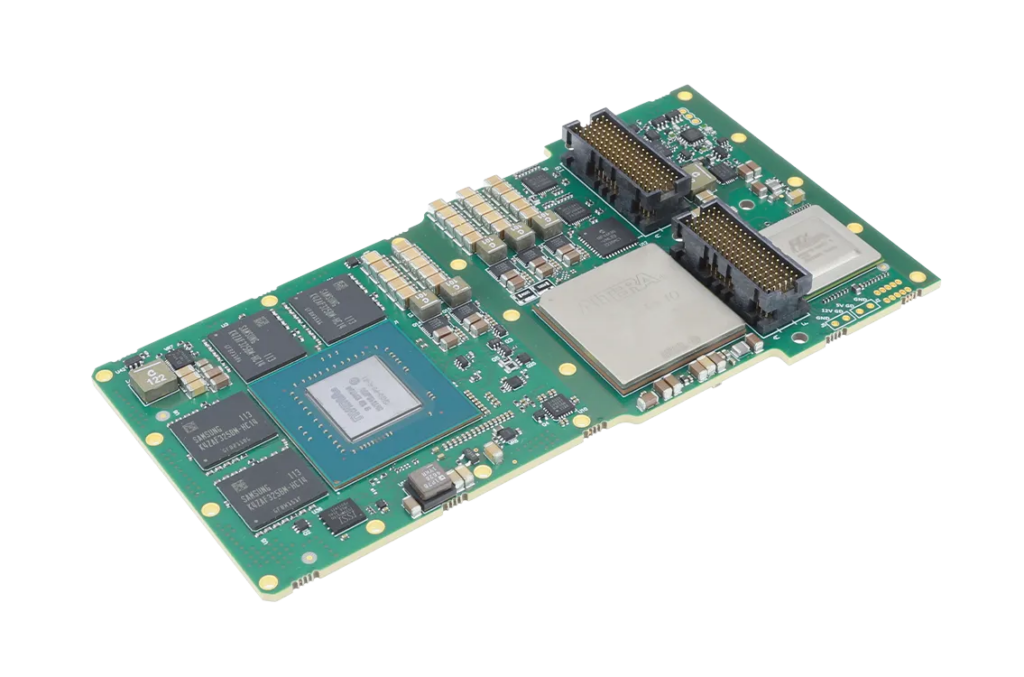

Additionally, the company specializes in designing and manufacturing electronic PCB assemblies for both prototype and production needs, ensuring rapid turnaround times.All designs are tailored to meet the unique challenges of UAV operations and can be ruggedized for extreme environmental conditions.

Among the advanced equipment available is a state-of-the-art pick-and-place machine capable of continuous operation for 24 hours,catering to urgent project needs. Its features include:

- Maximum board size of 350 x 190mm

- 4 operational heads

- 50 electric feeder slots

- 6 integrated cameras

- Mounting accuracy of 0.05mm

- Positioning accuracy of 0.01mm

- Repeatability of 0.02mm

The WP500-1 SmartDVD (Digital Voltage Detector) serves as a complete handheld testing unit for armament systems. It has been utilized in 14 Foreign Military Sales (FMS) countries on aircraft from Boeing and Lockheed Martin, making it ideal for Group 5 UAVs or other unmanned platforms equipped for munitions. This versatile device allows users to conduct automated and customizable test procedures, performing a variety of functions for testing airborne weapon systems and equipment.

It offers complete multiplex bus testing capabilities in accordance with MIL-STD-1553 and features an LCD digital display that provides real-time measurement data, easily readable in all lighting conditions.The rechargeable lithium-ion battery supports up to 50 hours of operation.

For further information about WilliamsRDM and their manufacturing capabilities, as well as UAV support equipment, please visit their profile page:

https://www.defencesource.com/company/williamsrdm/