This article delves into seven innovative methods for evaluating brushless motors using Tyto robotics’ thrust stands, along with insights on automating these assessments.

A thrust stand serves as an invaluable instrument for assessing brushless motors adn propellers. It streamlines the testing process significantly,particularly through automation. With automated testing, you simply initiate the process and monitor as the test executes autonomously, collecting data in real-time.

seven Essential Tests for Brushless Motors:

- Step Test

- Sweep/Ramp Test

- Endurance Test

- Closed Loop Control/Constant Thrust Test

- 90% Settling Time Test

- Flight Replay Test

- Sinusoidal and Chirp Signal Tests

Setting Up Yoru Tests

This discussion references two software applications that complement our thrust stands:

-

RCbenchmark Software

– offers a sampling rate of up to 50 Hz, compatible with Series 1580 and Series 1780.

-

Flight Stand Software

– provides a sampling rate of up to 1,000 Hz, suitable for Flight Stand 15/50/150.

The data presented in the accompanying videos was gathered using the Series 1580 test stand.

Figure 1: Propulsion systems evaluated in a wind tunnel

1.Step Test

What is a Step Test?

A step test involves guiding your propulsion system through a series of signal increments, either in a consistent or varied manner. For instance, you might start your throttle at 25% and increase it in 5% increments up to 50% (25%, 30%, 35%, 40%, 45%, 50%).

At each increment, a specific settling time is observed, allowing the system to stabilize before capturing data.

Why Conduct a Step Test?

There are several compelling reasons to perform a step test,as it is one of the more straightforward assessments available.

Primarily, a step test is highly repeatable, allowing you to execute it consistently for comparative analysis of diffrent propulsion configurations, as the data collection points remain constant.

Additionally, it provides insights into system performance across various operational points. For example, how does efficiency differ at 55% throttle compared to 60%? What are the power consumption levels at 80% versus 85% throttle?

A step test can effectively address these inquiries through a simple protocol.

Executing a Step Test

To design a step test,you must identify the operational points you wish to investigate. Are you interested in examining the entire range of signal inputs or focusing on a specific flight phase?

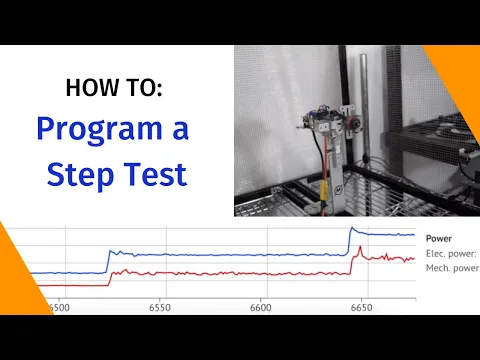

Once established, you can input these points into a test script, such as the one available in the RCbenchmark software (figure 2). Specify your minimum and maximum values, the number of steps, and the settling time between each step.

Steps can be entered manually or imported from a spreadsheet.

Figure 2: Automated test script for a step test

2.Sweep/Ramp Test

What is a Sweep/Ramp Test?

In a sweep test (also known as a ramp test), data is continuously gathered while your propulsion system smoothly transitions from one throttle setting to another.

Unlike a step test, there are no pauses; data is collected continuously throughout the transition.

Such as,you might set your starting throttle at 40% and your maximum at 80%,collecting data throughout the increase.

Why Conduct a Sweep/Ramp Test?

A sweep/ramp test enables you to evaluate a complete range of ESC operating points between two values. It functions similarly to a step test but with an infinite number of steps, eliminating the need for manual entry of each step.

this method is beneficial for throttle curve analysis and examining signal aliasing effects.

However,the number of data points collected is not fixed,which means comparisons can still be made,but data from different tests may not align precisely as they would in a step test.

Moreover, the resulting data files can become quite large, complicating analysis.

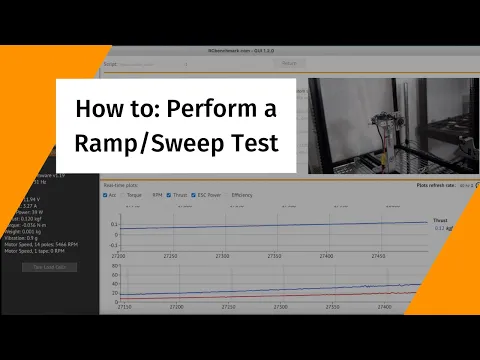

Executing a Sweep/Ramp Test

The RCbenchmark software includes a pre-written sweep test script that allows users to input their custom values. Users enter a minimum starting value, a maximum peak value, and the desired transition time between the two, which dictates the sweep speed.

It’s crucial to ensure that the sweep is performed slowly enough to minimize the torque from the propeller’s acceleration, preventing any impact on the readings. A sufficiently slow ramp will mitigate this effect.

3. Endurance Test

What is an Endurance Test?

Endurance testing encompasses any assessments designed for extended durations, aimed at evaluating the limits of the propulsion system or its components.

Examples include:

- Thermal endurance test – assessing motor performance over several hours in elevated temperatures.

- Bearing endurance test – determining the operational lifespan of a bearing before wear occurs.

- Icing endurance test – evaluating propeller performance over time in cold, humid conditions.

Why Conduct an Endurance Test?

Endurance testing is beneficial at various stages of the design process. It aids in selecting optimal components and creating precise technical documentation.

Moreover,endurance testing is critical for safety and reliability,assisting in drone certification by demonstrating component longevity and safe operational limits.

It also informs drone maintenance schedules by indicating when components require servicing.

Executing an Endurance Test

Any throttle pattern can be utilized for endurance testing,including step,sweep,sinusoidal,flight replay,etc. The parameters for the test depend on your design objectives.

Examples include:

- Thermal endurance test – operate your propulsion system at a constant throttle for an extended period in a warm environment, monitoring performance changes over time.

- Bearing endurance test – run your propulsion system through a repetitive sequence of steps under standard conditions, tracking how many hours of operation the bearing withstands before showing wear.

- Icing endurance test – operate your propulsion system through a smooth repeating signal in cold, humid conditions, observing performance changes as ice accumulates.

The RCbenchmark software can assist in designing your endurance tests using the pre-written script, “Custom steps sequence” (figure 3). Users create a test sequence by defining the number of steps, throttle values at each step, and the duration of each step.

The sequence can be repeated as needed, with data samples recorded at the midpoint of each step.

Figure 3: Editable script for endurance testing

4. Closed Loop control/Constant Thrust Test

What is a Closed Loop Control/Constant Thrust test?

In a closed loop control test, also known as a constant thrust test, the system continuously monitors sensor data and adjusts the throttle to maintain a specified thrust/power/RPM, as defined by the user.

An example of this is a PID controller, which detects discrepancies between the target and actual values, applying corrections based on proportional control with integral and derivative adjustments.

Why Conduct a Closed Loop Control Test?

This test is designed to keep your desired variable constant, even as other system parameters fluctuate.

As a notable example,as a LiPo battery discharges and voltage decreases,the throttle will adjust to sustain the programmed thrust/power/RPM.

This is advantageous in various scenarios, such as flight design, battery testing, or endurance assessments.

Executing a Closed Loop Control Test

To run a closed loop control test using the RCbenchmark software, you will need to create a custom script using standard Javascript. Here’s a sample script to help you get started.

The script will require modifications to meet your specific objectives. The primary challenge lies in ensuring the system does not overcompensate, which could lead to oscillations around your target value, necessitating some tuning.

5. 90% Settling time Test

What is a 90% Settling Time Test?

A 90% settling time test gauges the duration it takes for a propulsion system to achieve 90% of its final RPM after a step input. This serves as a measure of a drone’s responsiveness.

It is indeed a dynamic assessment that should be conducted with a high sampling rate to ensure accuracy.

Why Conduct a 90% Settling Time test?

This test enables designers and control engineers to quantify the response time of the entire propulsion system, including the ESC, motor, and propeller. This information is valuable for analyzing drone performance and resilience, such as how quickly it recovers from disturbances like gusts of wind.

Executing a 90% settling Time Test

This test is straightforward to perform, as it is pre-programmed in the RCbenchmark software. The script sends a step input signal to your propulsion system, transitioning it from 0 to 100% throttle while simultaneously recording the time taken to reach 90% of the final RPM.

Acceleration is also documented to provide an estimate of the acceleration slope immediately following the step input. This data is included as an additional column in the output .CSV file.

Figure 4: 90% Settling time test script

6. Flight Replay Test

What is a Flight Replay Test?

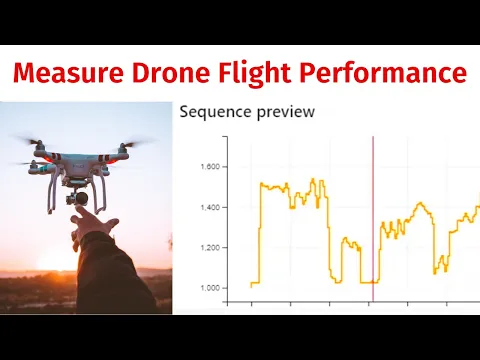

A flight replay test allows you to replicate a previous flight in a controlled environment using your propulsion system. This can be achieved by utilizing throttle data recorded by your onboard flight computer during a past flight.

Why Conduct a Flight Replay test?

This testing method is advantageous as it enables you to evaluate your propulsion system’s performance at various flight stages. You can identify which phases consume the most power and which are the most efficient.

This approach is one of the most precise ways to replicate flight operations, especially when combined with wind tunnel testing. It is indeed particularly useful for estimating battery life,providing insights that can lead to modifications in your drone design or flight procedures.

Executing a Flight Replay Test

Begin by exporting the throttle data from a flight to your computer. You can then import this file into the Flight Stand software as a .CSV file to create a custom test script. If using the RCbenchmark software, a custom script will need to be developed.

Once your propulsion system is connected to the thrust stand, the software will replay the throttle points through your system, allowing you to observe real-time changes in thrust, torque, RPM, power, and more.

7. Sinusoidal and Chirp Signal Tests

What are Sinusoidal and Chirp Signal Tests?

In a sinusoidal test,the propulsion system is controlled using a smooth sine wave signal,prompting the motor to vary its speed continuously.The system traverses a full range of throttle points while recording data.

Conversely, during a chirp signal test, a sine wave signal is sent to the propulsion system, but the frequency changes progressively over time (figure 5).The signal frequency may either increase or decrease, while the amplitude remains constant.

Figure 5: Structure of a chirp signal (Source: Wikiwand)

Why Conduct Sinusoidal or Chirp Signal Tests?

A sinusoidal test provides insights into your system’s performance across a wide array of operating points. the continuous data collection resembles a sweep test and is beneficial for endurance assessments.

A chirp test allows users to evaluate the full range of speed variations of an ESC, revealing how quickly and to what extent the ESC reacts to throttle adjustments.

This test also enables observation of system stability under a higher frequency of commands, often serving as a validation method for engineers to ensure control system stability across all frequencies.

Executing Sinusoidal and Chirp Signal Tests

For sinusoidal tests, a pre-written script for generating a sinusoidal function in the ESC output is available: https://cdn-docs.rcbenchmark.com/scripts/sinewave.js. This can be utilized with the RCbenchmark software.

conducting a chirp signal test requires writing a custom script, with the sinusoidal script serving as a solid foundation.

Keep in mind that the update rate is constrained by the ESC protocol and USB interaction speed. Therefore,we recommend not exceeding a sine wave frequency of 10 Hz when using the RCbenchmark software.

Conclusion

The automated brushless motor tests outlined in this article are crucial for optimizing propulsion systems. The insights gained can highlight practical areas for enhancement within your system.

If your interested in conducting these tests in your own facility, consider our Series 1580 for small drones, the Flight Stand 15/50 for medium drones, and the Flight Stand 150 for larger drones and eVTOL applications.

As always, our robust software solutions are available at no cost.