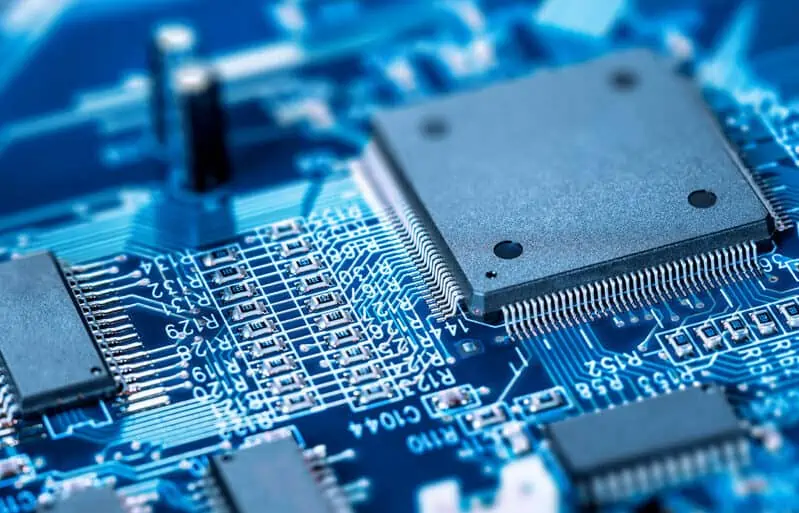

Choosing the right conformal coating for electronic devices necessitates a complete understanding of the working surroundings and potential reliability challenges. Essential considerations include the need for biocompatibility, transparency, and the required thickness of the coating.

HZO offers a solution with its ultra-thin Parylene coatings,designed to safeguard mission-critical electronics and PCB assemblies in unmanned aerial vehicles (UAVs) and robotics.

Parylene is renowned for its remarkable chemical resistance and performance across a broad temperature spectrum,making it an ideal choice for protecting components and integrated circuits,particularly in environments exposed to corrosive substances,humidity,immersion,and various chemicals.

Understanding Parylene’s Chemical Resistance

Parylene conformal coatings are chemically inert, exhibiting resistance to solvents at ambient temperatures and up to 150° C. This resilience helps prevent erosion, delamination, and other forms of degradation, ensuring consistent performance.

These coatings are resistant to inorganic reagents, including strong acids and alkalis.Parylene coatings demonstrate chemical resistance to a variety of solvents and reagents, such as:

Acids, Bases, and Corrosives

- 10% Hydrochloric acid

- 10% Sulfuric acid

- 10% Nitric acid

- 10% Hydrofluoric acid

- 10% Sodium hydroxide solution

- 10% Ammonium hydroxide solution

- Hydrogen peroxide in water (H2O2)

Organic Solvents

- n-Octane

- Toluene

- Chlorobenzene

- Pyridine

- 2-Propanol (IPA)

- Acetone

Explore HZO’s comprehensive Parylene datasheet >>

the Unique Properties of Parylene C

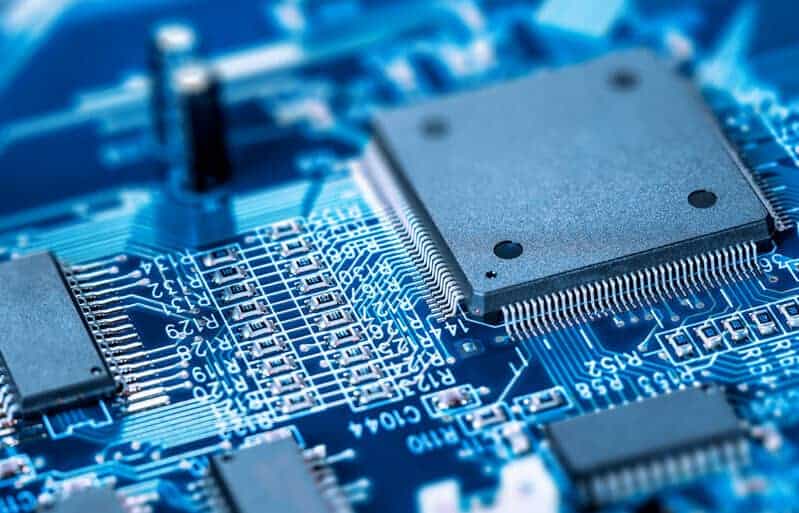

Various types of Parylene exist, including Parylene N, C, and F (VT-4), each tailored for specific applications.

Parylene C, in particular, is adept at withstanding exposure to corrosive liquids and solids, as well as a wide range of solvents and reagents commonly used in electronic processing, including diluted acids, bases, and organic solvents like isopropyl alcohol.

The Chemical Vapor Deposition (CVD) Technique

The remarkable chemical resistance of Parylene is largely attributed to the innovative vacuum deposition technique known as chemical vapor deposition (CVD).

This method allows polymer chains to tightly pack together, enhancing Parylene’s resistance to chemicals that might or else penetrate and react with the coating.

As a result,the film produced is chemically more robust compared to those derived from liquid applications or assembled monolayers.

For a detailed guide on CVD, click here >>

If you believe Parylene is a fit for your needs, reach out to HZO below, or learn more about scalable Parylene coating equipment and Parylene masking automation.