CRP Technology: Pioneering 3D Printing for Aerospace and UAV Industries

CRP Technology stands at the forefront of certified 3D printing, specializing in the UAV (unmanned aerial vehicle), aerospace, and space sectors. They are renowned for their Windform® series of composite materials, meticulously engineered to meet the rigorous demands of these industries. UST is thrilled to announce a partnership with CRP Technology, and we will be showcasing their innovative solutions and expertise across our platforms over the coming year.

We have recently unveiled CRP Technology’s UST supplier profile, crafted in collaboration with their team. This Silver profile highlights their advanced capabilities and the lightweight yet robust Windform composites, which are perfectly suited for producing flight-ready components capable of enduring the extreme conditions found in aerospace and space missions.

To delve deeper into CRP Technology’s offerings, check out the video below:

Unmatched Performance with Windform Composites

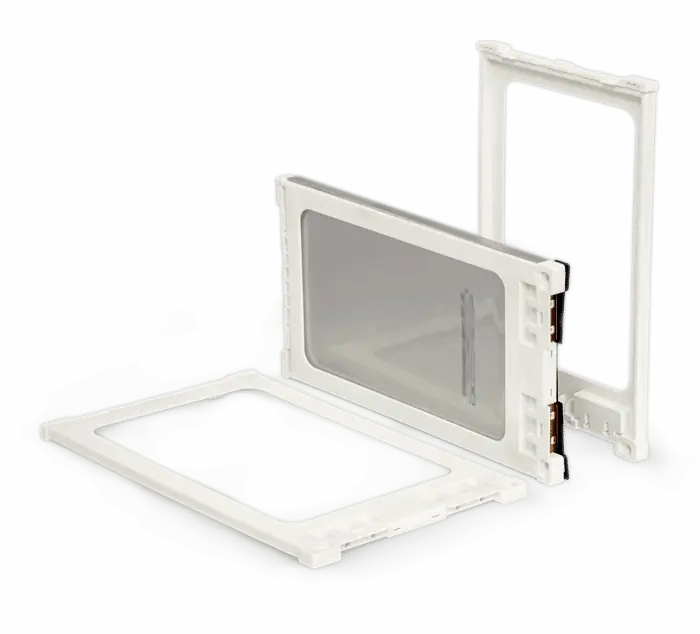

The carbon and glass-fiber Windform composites boast the best weight-to-density ratio in the industry, allowing drone components to be up to 60% lighter than those produced through conventional methods. This important reduction in weight leads to longer flight durations, enhanced payload capacities, and lower fuel consumption for UAVs and UAS.

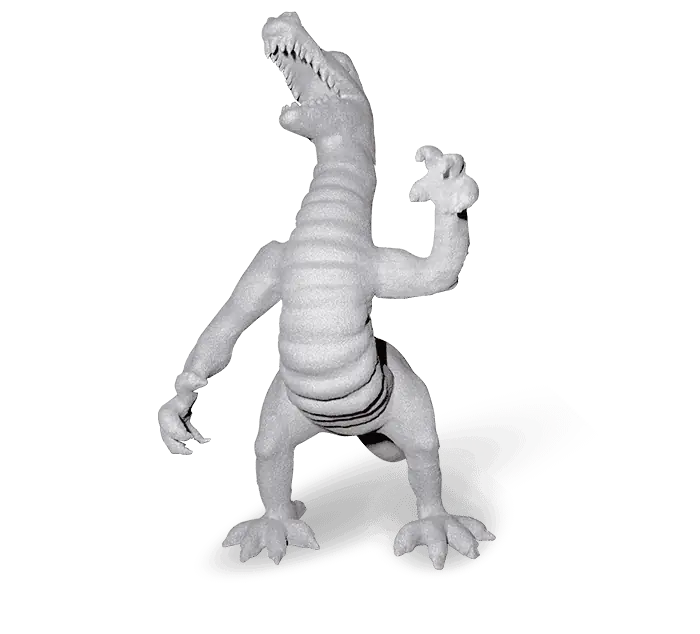

Beyond their lightweight nature, Windform composites are engineered for toughness and durability. Rigorously tested in real-world aerospace scenarios,these materials can endure extreme temperatures,corrosive chemicals,and intense shock and vibration. UAVs, satellites, and deployers crafted from Windform are currently engaged in long-term missions in some of the most challenging environments.

Diverse Range of Windform Composites

The Windform family encompasses a variety of options,catering to nearly every drone design requirement:

- Windform SL: A low-density polyamide with high stiffness and exceptional heat resistance,perfect for UAV airframes and arms.

- Windform RS: A lightweight carbon-filled composite known for its high stiffness, strength, and outstanding impact resistance, ideal for mission-critical components.

- windform SP: designed for environments with significant shock and vibration, this material is both impact-resistant and waterproof.

- Windform XT 2.0: A space-grade composite that offers excellent strength and stiffness, suitable for both functional prototypes and production runs.

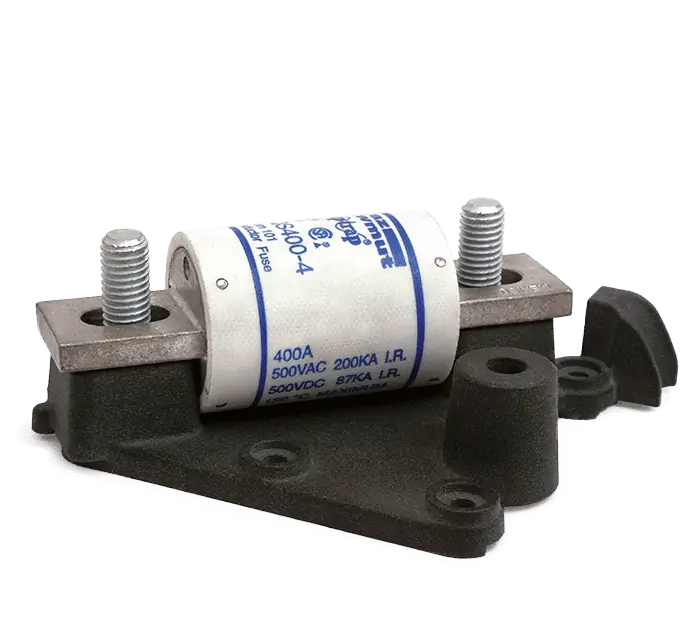

- Windform FR1: A halogen-free flame-retardant composite compliant with UL 94 V-0 and FAR 25.853 standards.

- Windform FR2: A glass fiber-filled flame-retardant composite that also provides electrical insulation.

- Windform GT: An electrically insulated, glass fiber-filled material known for its flexibility and resistance to impact, shock, and vibration.

- Windform LX 3.0: A next-generation glass fiber composite that delivers an excellent surface finish,ideal for aesthetically demanding components.

- Windform RL: A rubber-like thermoplastic that withstands repeated bending and torsion while providing good shock absorption.

- Windform FX Black: An impact-resistant polyamide with properties akin to polypropylene and ABS injection-molded parts.

- Windform TPU: A thermoplastic polyurethane that excels in flexibility and shock absorption, making it perfect for robotic components like joints and pipes.

- Windform GF: A polyamide filled with aluminum and glass fiber,offering excellent surface definition,suitable for intake ducts and fuel systems.

For further insights into CRP Technology and their Windform composites tailored for aerospace and space applications, please visit their profile page.