Dymax’s Dual-Cure 9771 Conformal coating: Exceptional protection for PCBs

Engineered specifically for the aerospace and defense sectors,the Dual-Cure 9771 conformal coating from Dymax provides outstanding protection for printed circuit boards (PCBs) used in missiles, satellites, and other space applications, where harsh environmental conditions pose significant challenges.

This innovative coating utilizes both UV/Visible light and a secondary moisture-cure mechanism, ensuring thorough curing even in shadowed areas.

The 9771 conformal coating is compliant with stringent standards, including ASTM E595 for low outgassing, UL 94 V0, UL 746E, and is pending approval for MIL-I-46058C and IPC-CC-830-B. It also adheres to the RoHS2 Directives 2015/863/EU.

Key Features & Advantages

Complies with ASTM E595 for low outgassing

- Meets Mil-Std 883 Method 5011 for low ionic content

- UL 746-E and UL94V-0 flammability ratings

- Dual curing with UV/Visible light and moisture for shadow areas

- Exceptional resistance to corrosion

- Resilient against temperature and humidity variations

- Bright blue fluorescence for easy inspection

This UV conformal coating ensures a cleaner PCB in extreme conditions due to its minimal outgassing and ionic content. it is especially suitable for safeguarding critical electronic components in military and aerospace systems, meeting the rigorous MIL-STD 883 Method 5011 standards for applications exposed to severe environments. Additionally, it is indeed listed in NASA’s MAPTIS database (Material Code 09841).

The 9771 features a highly visible bright blue fluorescent tracer, facilitating straightforward quality inspections under black light. As a Dual-Cure conformal coating, it effectively cures with both UV/Visible light and moisture, reaching shadowed areas. This 100% solids formulation serves as a lightweight option to solvent-based coatings, providing a thin yet robust protective layer for PCBs.

Performance & testing of 9771

According to Mil-Std 883 Junction Coating Type II, the 9771 has successfully passed several tests outlined in Mil-Std 883 Method 5011.7, including:

- Thermal stability and filler content analysis via thermogravimetric methods

- Specific ion content assessment

- Overall ionic content evaluation

- Hydrogen ion content (pH) measurement

- Volume resistivity testing

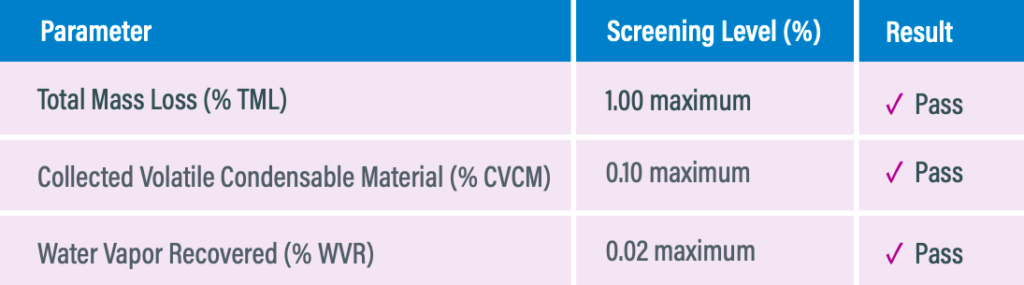

ASTM E595 Outgassing Compliance

ASTM B117 Salt Fog Resistance Testing

Testing Details: Coating thickness of 0.005″ (127) was subjected to 35°C in a 5% salt solution for 500 hours.

Results: No significant changes were observed, including flashover, sparkover, or breakdown during voltage transient tests (based on UL-746E), and no corrosion was detected on the boards.

Heat & Humidity Testing at 85°C/85% R.H.

Dymax specializes in manufacturing light-curable adhesives, coatings, and maskants, along with compatible dispensing and curing equipment. Their focus is on developing solvent-free materials that cure quickly and cleanly, enabling engineering teams to achieve more with less environmental impact.

Discover more >>