Revolutionizing Torque Performance: Alva Industries’ FiberPrinted™ Motors

Alva Industries has introduced its innovative FiberPrinted™ motors, which excel in torque performance, surpassing the peak torque capabilities of customary iron-cored motors.

The Limitations of Conventional Electric Motors

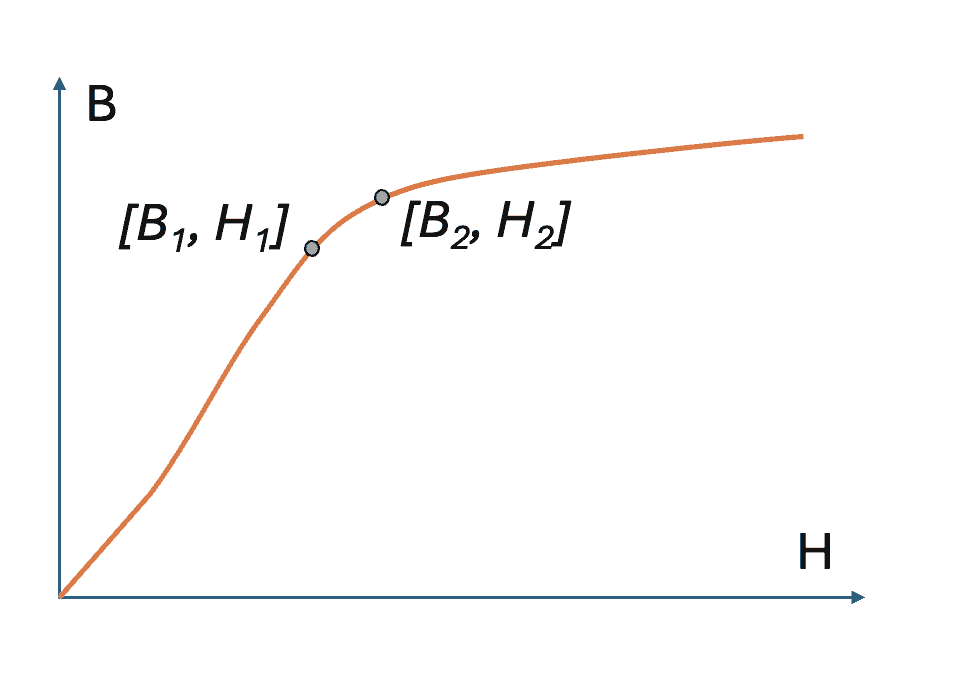

Traditional electric motors rely on ferromagnetic cores to support their windings, enhancing both magnetic flux density and energy density.However, these materials face saturation when the external magnetic field, denoted as H, increases to a point where it no longer substantially boosts magnetization.This phenomenon leads to a plateau in the total magnetic flux density, represented as B.

This saturation effect is illustrated in the magnetization curve (B-H curve) of ferromagnetic materials, where the curve bends to the right. The saturation point is identified at coordinates [B2, H2], although the curve begins to flatten out earlier, around [B1, H1].

Fig. 1. B-H curve

Understanding Saturation in Motor Cores

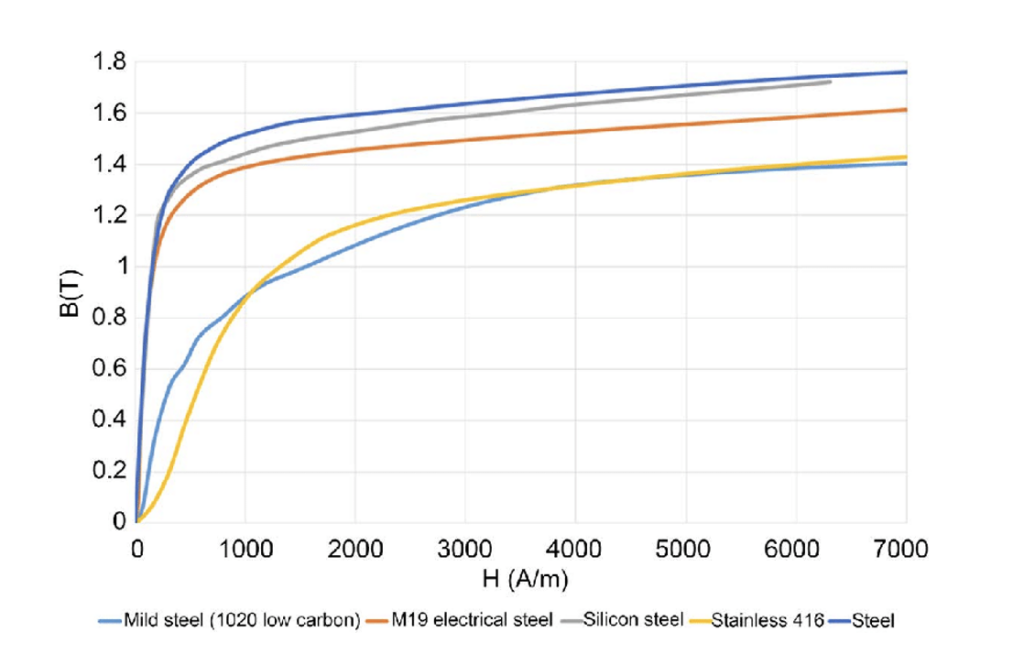

Motor cores are typically constructed from laminated electrical steel sheets, which are also ferromagnetic and thus susceptible to saturation. Different grades of steel exhibit varying saturation levels, as depicted in the B-H curves of various steel types.

Fig. 2. B-H curves of different steel types.

Magnetic Permeability and Its implications

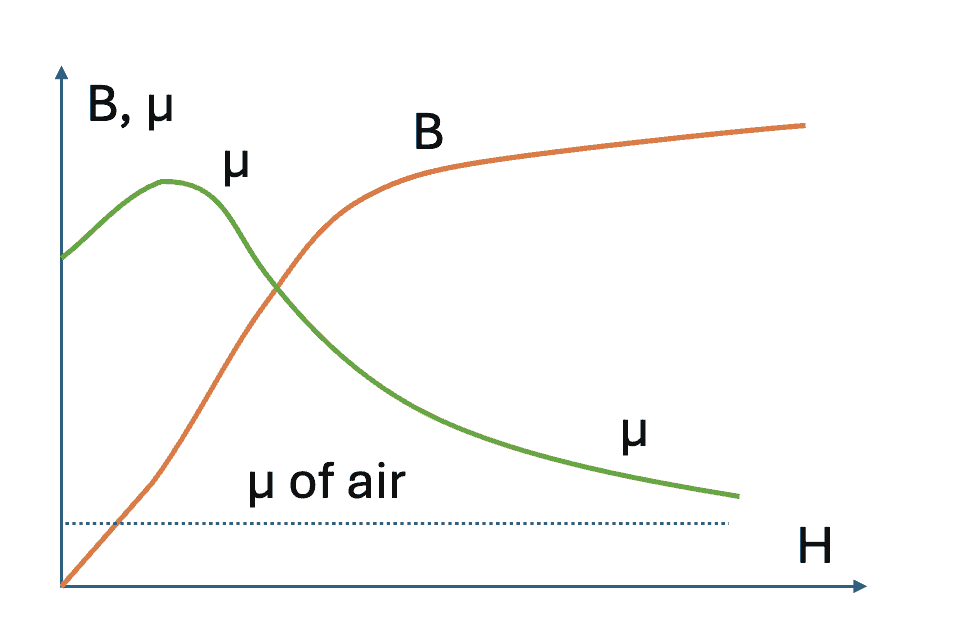

The relationship between the magnetic field strength (H) and magnetic flux density (B) is defined by the equation B = μH, where μ represents magnetic permeability. as one moves along the B-H curve, the value of μ changes. At elevated H values, the permeability decreases, approaching that of free space, such as air or a vacuum.

Fig.3. Variation of B and μ with increase of H.

Current Flow and Its Impact on Motor Performance

In electric motors, the external magnetic field H is produced by currents flowing through copper windings, making H directly proportional to the current. Once saturation occurs, any further increase in current results in a proportional rise in H, while the permeability μ of the steel diminishes, causing its magnetic properties to resemble those of air.

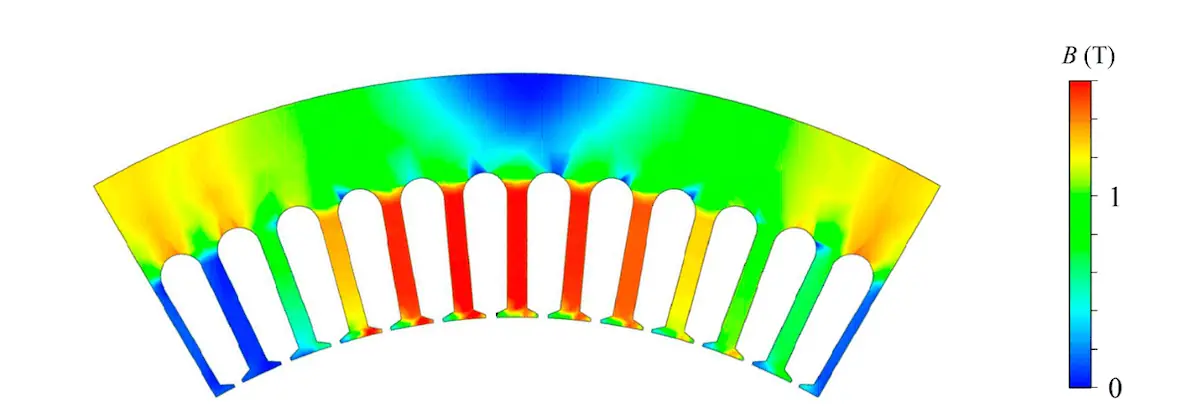

In practical applications, the motor components that carry the highest currents can reach full saturation, as indicated by the red areas in the saturation diagram.In magnetic terms, these regions effectively lose their ability to conduct magnetic flux.

Fig. 4.Saturation of iron teeth.

Evaluating Motor Efficiency and Torque Output

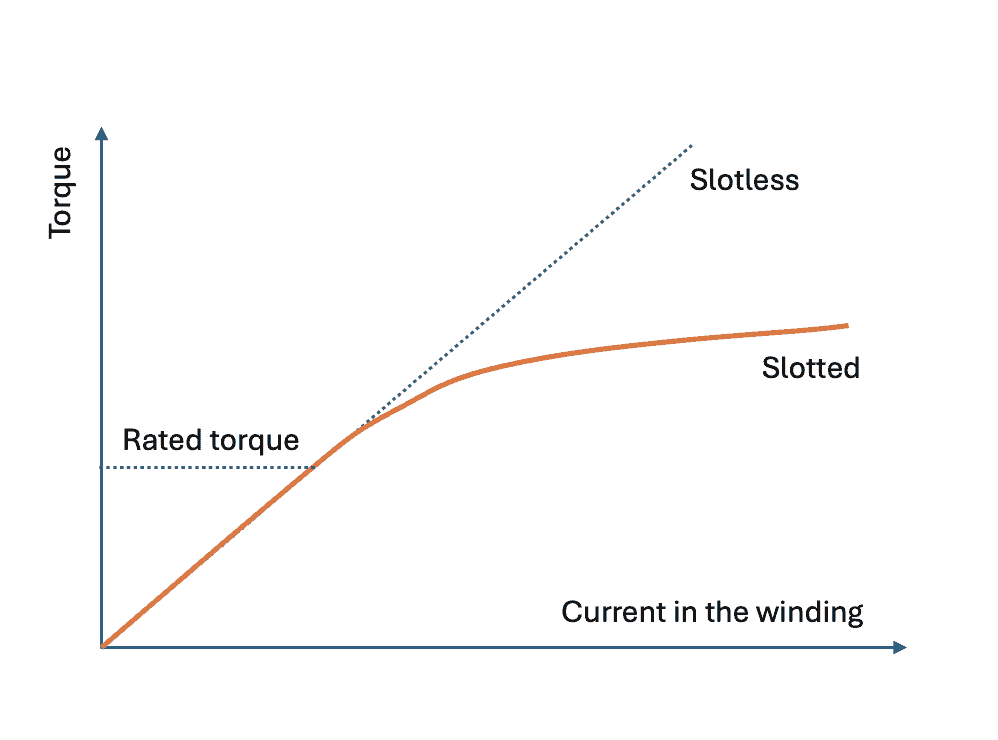

The efficiency of a motor is significantly influenced by its capacity to convert input current into output torque.A linear relationship between current and torque is essential for optimal performance, as it simplifies control across the motor’s operational range.

As input current increases,traditional iron-cored motors may reach saturation,which restricts their torque output. Conversely, slotless motors can maintain a proportional increase in torque relative to current, within practical limits.

Fig. 5. Torque vs current with and without the magnetic saturation.

Advancements in Motor Technology

Thanks to these advancements, conventional slotless motors can achieve peak torques that are comparable to or even exceed those of traditional iron-cored motors for short durations.

Alva Industries’ FiberPrinted™ motors, which feature an enhanced copper fill factor and optimized winding design, demonstrate superior torque capabilities, frequently enough outperforming iron-cored motors in peak torque scenarios.

Modeling studies suggest that even at currents reaching ten times the rated capacity, the back iron in FiberPrinted™ motors remains far from meaningful saturation. Thus, under standard operating conditions, these motors can be regarded as effectively ‘saturation-free.’

Read the original article >>