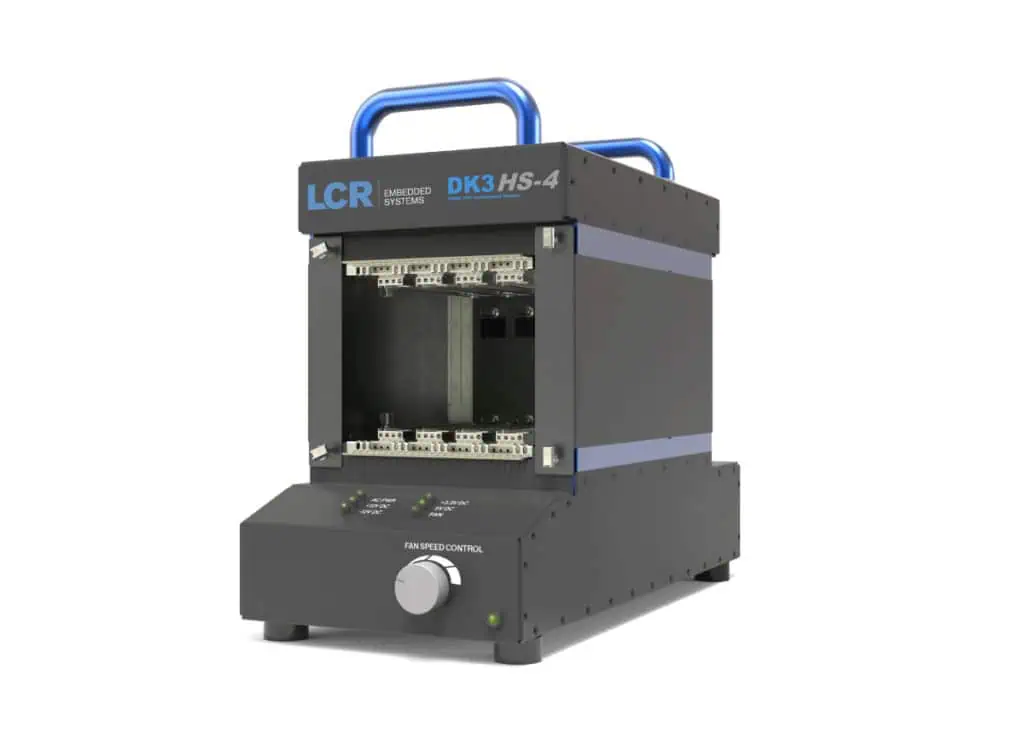

available in both 3U (left) and 6U (right) configurations, VPX development chassis expedite submission development and minimize time to market.

Discover how LCR Embedded Systems’ VPX development chassis enhance integration and testing for critical defense and aerospace projects, providing modular adaptability, high-speed connectivity, and superior cooling to meet the demands of advanced embedded computing environments. Learn more > >

The Significance of VPX Technology in Modern Defense Systems

As the requirements for defense and aerospace systems escalate in terms of performance and reliability, VPX (VITA 46) technologies have emerged as vital components in contemporary embedded computing. Designed to supersede VMEbus, VPX presents a scalable architecture that accommodates high-speed data transmission, robust construction, and modular adaptability essential for mission-critical applications. Its ongoing development, including alignment with SOSA standards, has solidified VPX’s position as a essential element in today’s defense-grade computing solutions.

Prototyping and Testing with VPX Development Chassis

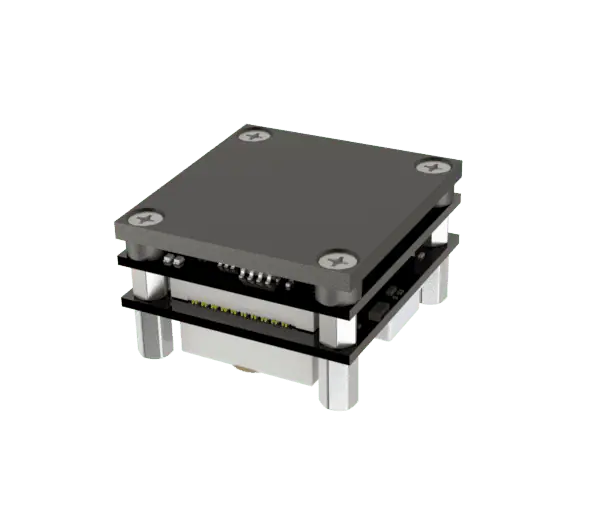

The VPX development chassis is indispensable for system prototyping, integration, and testing. these platforms offer engineers a flexible surroundings to assess single board computers and plug-in cards (PICs),facilitating straightforward debugging,rapid board exchanges,and efficient reconfiguration. More elegant systems come equipped with full backplanes, enabling developers to replicate entire system architectures and analyze data flows prior to transitioning to production hardware.

Connectivity solutions for Enhanced Development

Establishing optimal connectivity between boards is crucial during the development phase. Since off-the-shelf backplanes with tailored profiles are seldom available, cabled solutions present a versatile choice. By utilizing power and ground (P and G) backplanes alongside high-speed cabling, engineers can iteratively develop and refine the desired system profile without incurring the time and expense associated with custom backplane manufacturing. LCR facilitates this development strategy with chassis designed to integrate Meritec cabling systems, optimizing signal management and minimizing integration risks.

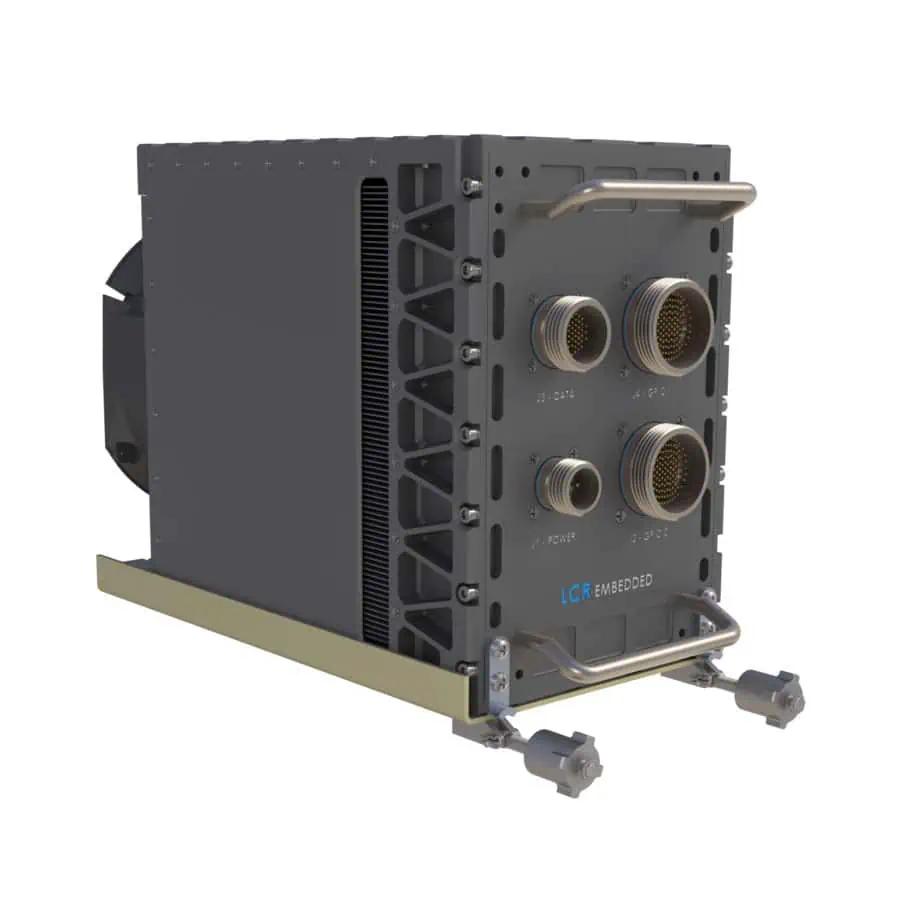

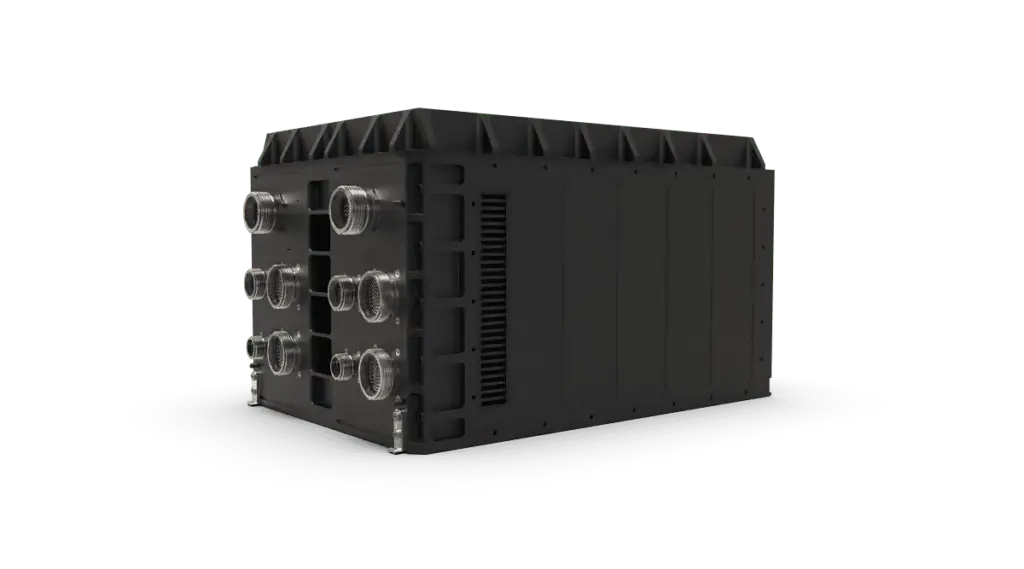

Form factor Options: 3U vs. 6U VPX

LCR’s development chassis accommodate both 3U and 6U VPX form factors. The compact 3U VPX is particularly favored in scenarios where space and weight constraints are paramount, such as edge processing applications. Conversely, the larger 6U VPX form factor provides additional room for high-performance processing, extra I/O, and intricate component arrangements. LCR’s DK3HS-4 chassis supports high-speed 3U development with four slots and data rates reaching up to 100Gb. The DK6 chassis, tailored for 6U VPX, offers open-frame versatility with provisions for both air and conduction cooling, along with rapid backplane modifications.

Addressing Cooling Challenges in High-Power Applications

As power demands rise in applications like electronic warfare, radar, and SIGINT, effective cooling solutions become increasingly critical. While conduction-cooled systems are the norm,liquid cooling is gaining traction as a promising alternative. Development chassis must evolve with advanced thermal management strategies to accommodate escalating power densities.

Accelerating System Design with LCR’s VPX Platforms

LCR’s VPX development platforms streamline system design and mitigate risks, supporting application development from initial concept through to final deployment with robust, customizable solutions.

Read the original article.