Dymax emphasizes the importance of ASTM E595 outgassing assessments for light-curable substances utilized in the manufacturing of avionics and optoelectronic components.

As a premier producer of UV/LED light-curable materials compliant with ASTM E595, Dymax recognizes the essential need for manufacturers to ensure that their final products adhere to stringent standards.

Understanding Outgassing

Outgassing, or off-gassing, occurs when gases are released from adhesives or coatings during the light-curing phase or when subjected to extreme conditions post-curing.

This phenomenon can happen when rapid polymerization or chemical reactions take place, causing trapped gases to escape due to exposure to light, heat, or vacuum. The majority of outgassed materials typically consist of moisture from the raw components, along with trace impurities and unreacted monomers.Such outgassing can lead to unintended weight loss or material deposition, perhaps disrupting the functionality of the final components.

Significance of Outgassing in Light-Curable Materials

Evaluating light-curable materials for outgassing is vital for several reasons, especially to prevent contamination in environments where the components will be utilized.

Concerns related to outgassing include:

- Indications of degradation or structural changes in substrates, coatings, or adhesives

- Contamination of surfaces that must remain pristine to maintain their electrical characteristics

- Warnings of potential corrosion, crazing in plastics, or other mechanisms that could weaken surfaces

ASTM E595 – The Outgassing Standard

The ASTM E595 test, frequently enough referred to as the NASA Low Outgassing Specification, is a widely accepted method for assessing outgassing. Manufacturers frequently require this test to validate adhesives or coatings used in processes like assembling printed circuit boards for optical, electronic, and aerospace/defense applications.

This test is conducted at 125°C (257°F) under a vacuum of 5 X 10-5 Torr for 24 hours. The results measure Total Mass Loss (TML %) and Collected Condensable volatile Material (CVCM %), with Water Vapor Regain (WVR %) also reported.

TML indicates the percentage of weight loss during testing, with a specification threshold of <1.00%. CVCM measures the percentage of outgassed materials that condense on a collector, with a limit of <0.10%. Even though WVR is not typically a pass/fail criterion, it provides insight into the proportion of TML attributed to water vapor.

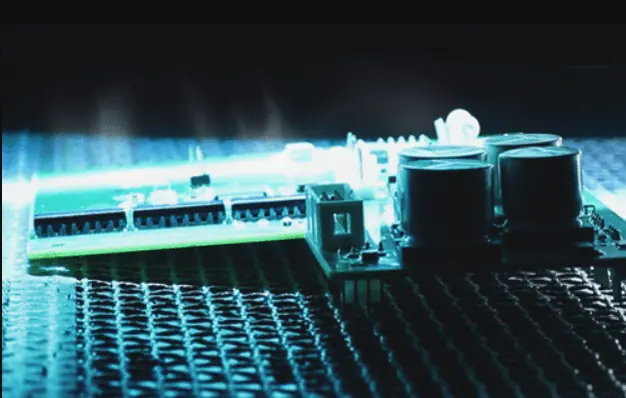

Applications in Avionics and Optoelectronics

In avionics and optoelectronic sectors, CVCM is particularly crucial, as it may signal unwanted material deposition on optical components, potentially leading to fogging or loss of electrical continuity. Adequate ventilation or air circulation during the curing process can help reduce outgassing redeposition,although this becomes more challenging in vacuum conditions.

Conducting outgassing tests is essential for assuring manufacturers that their components comply with critical standards, thereby minimizing the risk of part failures.

Dymax offers a variety of light-curable materials that align with ASTM E595 standards,featuring low TML and CVCM properties.