LCR Embedded Systems recognizes the necessity for modern defense electronics to function reliably in some of the most challenging environments on Earth. Discover more >>

To guarantee both durability and performance, military systems utilizing VPX and SOSA-compliant architectures must adhere to rigorous environmental standards, with MIL-STD-810 being pivotal in the ruggedization process.

From advanced electronic warfare (EW) and signal intelligence (SIGINT) systems to real-time battlefield data processing, MIL-STD-810 testing ensures that these essential components can endure extreme temperatures, vibrations, and various environmental challenges.

The Significance of VPX and SOSA in Military Electronics

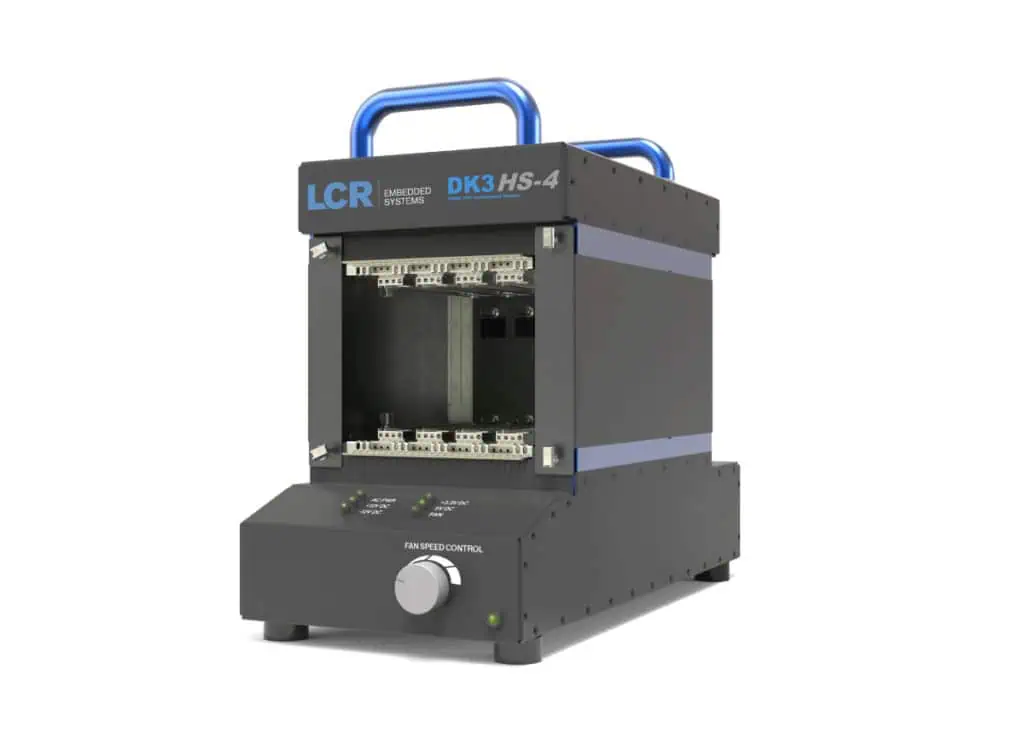

VPX (VITA 46) represents a cutting-edge open-standard architecture tailored for high-speed data transmission and modular scalability. It has emerged as the foundation for military applications that necessitate real-time processing of substantial data volumes, such as electronic intelligence (ELINT) and electronic support (ES) operations. OpenVPX enhances interoperability by standardizing backplane and chassis interfaces across diffrent manufacturers.

The Sensor Open Systems Architecture (SOSA) framework builds on VPX to foster modularity, interoperability, and reusability across defense systems. Designed to facilitate the swift integration of new technologies, SOSA promotes cost-effective and adaptable system development, emphasizing reduced downtime through the use of line-replaceable units (LRUs).

The Imperative for ruggedization in Extreme Conditions

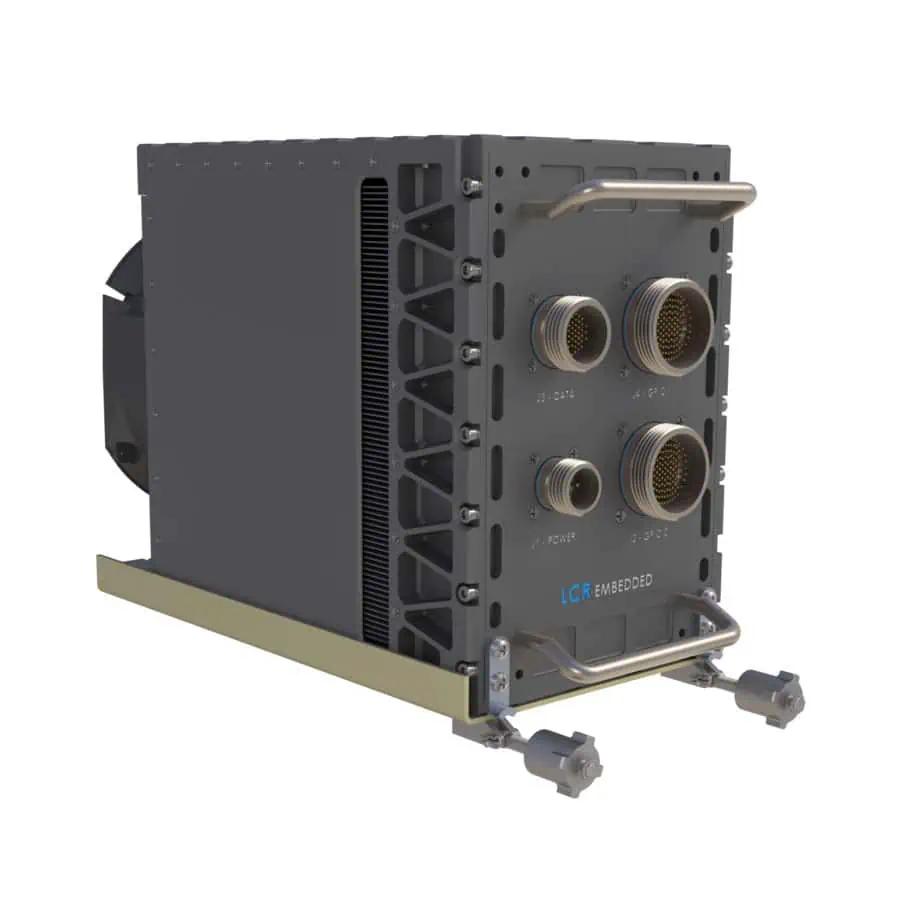

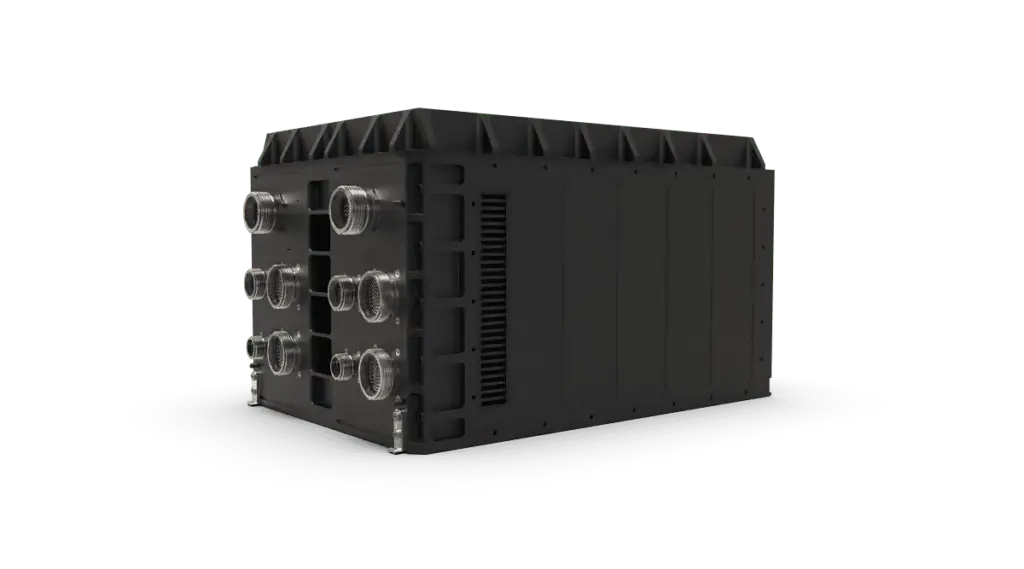

Systems based on VPX and SOSA are deployed in diverse environments—land, sea, and air—frequently enough facing severe conditions such as high-altitude pressure variations, exposure to dust and sand, intense shock and vibration, and drastic temperature changes. These systems are encased in robust VPX chassis and ATR (Air transport Rack) enclosures to ensure operational reliability in demanding settings.

MIL-STD-810 offers a thorough framework for evaluating defense electronics, confirming that VPX and SOSA-based systems maintain their reliability under authentic military conditions.

Essential MIL-STD-810 Environmental Assessments

1. Temperature Extremes and thermal management

military platforms operate in environments ranging from blistering deserts to frigid Arctic regions. MIL-STD-810 temperature assessments evaluate the capability of VPX and SOSA systems to function in extreme heat and cold. Many rugged VPX chassis utilize conduction cooling, where excess heat is dissipated through the chassis walls, ensuring stable operation.

2.Shock and vibration Resistance

Defense electronics used in vehicles, aircraft, and naval vessels are subjected to constant vibrations and occasional high-impact shocks. MIL-STD-810 tests determine whether VPX chassis and ATR enclosures can endure mechanical stresses without component failures, ensuring continued operation in SIGINT, FISINT (Foreign Instrumentation Signals Intelligence), and other data-intensive applications.

3. Dust, Sand, and Water Ingress Protection

In harsh environments like deserts and maritime operations, dust, sand, and water ingress present significant threats. MIL-STD-810 ingress testing ensures that rugged ATR enclosures and VPX chassis are sealed to prevent contaminants from compromising sensitive electronics.

4. Altitude and Low-Pressure Testing

High-altitude reconnaissance aircraft and unmanned aerial vehicles (UAVs) require electronics that can reliably operate in low-pressure conditions. MIL-STD-810 verifies that VPX and SOSA-aligned systems can withstand rapid altitude changes without performance degradation.

5. humidity and Corrosion Resistance

High humidity levels increase the risk of moisture-related damage,including corrosion and short circuits. MIL-STD-810 humidity assessments confirm that ruggedized ATR enclosures and VPX chassis effectively prevent moisture accumulation, often employing conformal coatings to safeguard critical components.

6. Electromagnetic Interference (EMI) Shielding

Electronic warfare and intelligence-gathering systems must be shielded against electromagnetic interference to maintain signal integrity. MIL-STD-810 testing ensures that VPX chassis and ATR enclosures provide effective EMI protection,allowing systems such as TECHELINT (Technical ELINT) and OPELINT (Operational ELINT) to operate without disruption.

Design Considerations for Compliance with MIL-STD-810

Meeting MIL-STD-810 testing requirements influences crucial design elements of rugged defense electronics:

- Material selection: Utilizing corrosion-resistant metals like aluminum and titanium enhances durability while keeping the structure lightweight.

- Thermal Management: Integrated heat sinks,forced air cooling,and conduction cooling techniques optimize thermal performance in extreme conditions.

- Modularity for Field maintenance: The LRU approach facilitates rapid replacements and repairs, minimizing system downtime during military operations.

As defense platforms increasingly depend on VPX and SOSA-based architectures for high-performance computing, ensuring ruggedization through MIL-STD-810 testing remains essential.By validating resistance to temperature extremes, shock, vibration, ingress, and EMI, this testing standard guarantees the long-term reliability of mission-critical systems deployed in the most demanding environments.

From electronic warfare to intelligence gathering, compliance with MIL-STD-810 ensures that VPX and SOSA-aligned defense electronics maintain operational effectiveness when it is indeed most crucial.

Explore the original article or visit the LCR Embedded systems website for more data.