SBG Systems has introduced an innovative Virtual Base Station feature within its Qinertia post-processing software. This advanced tool grants users access to offline RTK corrections sourced from over 7,000 base stations across 164 nations, substantially enhancing trajectory and orientation precision by analyzing inertial data alongside raw GNSS observables in both forward and backward directions.

The Virtual Base Station (VBS) capability establishes a virtual network tailored to a specific project, ensuring consistent, high-quality positioning accuracy that simulates short baseline PPK.This feature is notably beneficial for surveyors working in expansive areas or far from existing base stations, making it an excellent choice for corridor mapping. Once the mission concludes, Qinertia identifies the most pertinent reference stations, constructs a virtual network, and elevates accuracy to a centimetre level without experiencing convergence issues, even in densely populated urban settings.

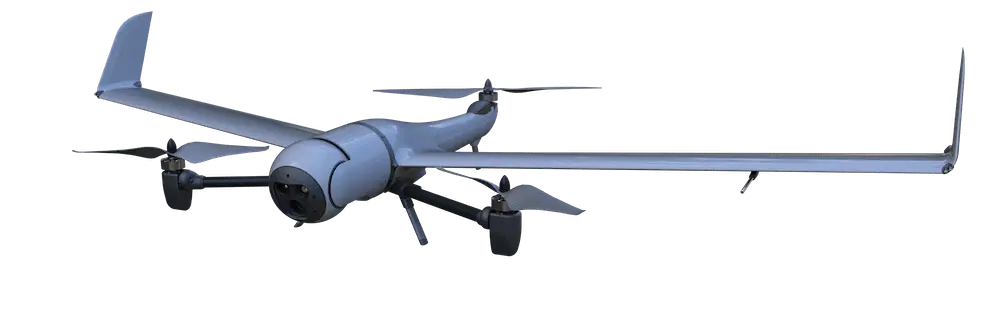

Qinertia is compatible with all GNSS receivers and third-party IMUs, automatically adjusting the VBS network to account for any inaccuracies in base station positioning. This ensures comprehensive quality control indicators are available to evaluate expected accuracy and reliability. The VBS technology can seamlessly integrate user-defined base stations with permanent network stations, enhancing precision in remote areas. The software operates with remarkable speed, parallelizing calculations for each base station in the virtual network while processing forward and backward computations simultaneously. A typical UAV (unmanned aerial vehicle) survey can be completed in under a minute.

The clever design of Qinertia software automatically determines the most suitable positioning technology for a given project, whether it involves a single base station, the Virtual Base Stations mode, or Precise Point Positioning computations. Users have the versatility to manually select their preferred mode and adjust the number of base stations, while qinertia concurrently re-evaluates and recalculates all parameters to ensure accuracy and consistency. Each step of the process can be manually verified,with a variety of quality control indicators available,including separation,standard deviation,bias,scale factor,lever arm,and detailed export statistics reports (RMS,min/max).