Nicomatic offers a wide array of fiber optic solutions tailored to meet the growing needs for high-speed data transmission, compact system designs, and strict electromagnetic interference (EMI) standards.

Instead of merely offering standard products, Nicomatic collaborates closely with clients to create bespoke optical systems that fulfill specific engineering challenges in unmanned systems.

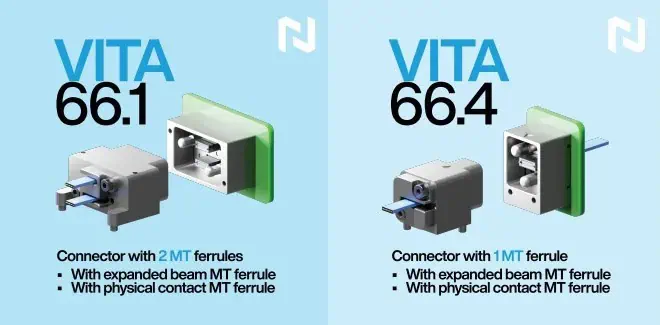

Integration of Backplane Solutions with VITA 66 Compliance

As VPX architectures become increasingly vital in embedded systems, Nicomatic delivers VITA 66-compliant solutions that facilitate optical connectivity through the backplane while maintaining durability and compactness.

The company supports both VITA 66.1 (utilizing two MT ferrules) and VITA 66.4 (featuring a single MT ferrule), providing:

- Robust, space-saving modules compatible with VPX backplanes

- Precision alignment of MT ferrules to minimize insertion loss

- Reliable performance under extreme shock, vibration, and temperature conditions

Nicomatic supplies optical sub-assemblies that are ready for integration and specifically designed to meet the mechanical and thermal requirements of clients.

optical Connectors in the VITA Series

Specialized configurations include the VITA 66.4 Dual setup, which incorporates two MT interfaces into the 66.4 form factor for enhanced capacity.

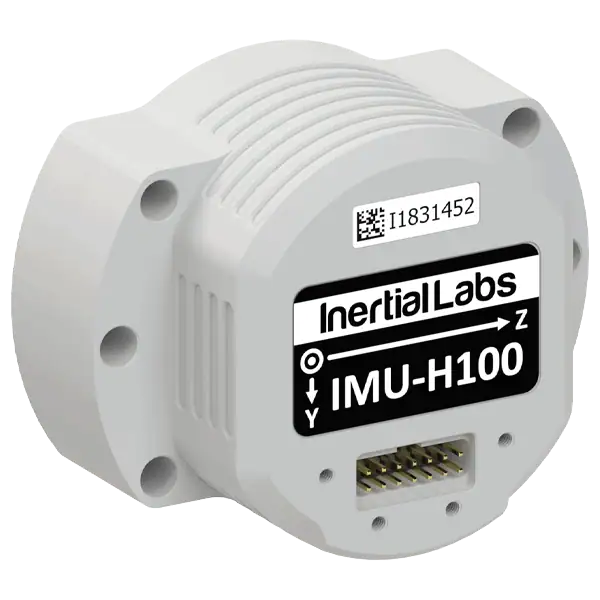

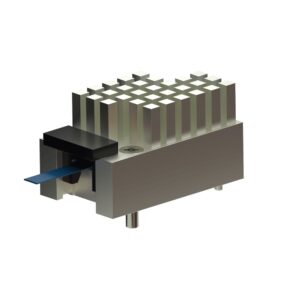

Compact Optical Transceivers for Local Signal Processing

These transceivers are compact and modular, suitable for tight configurations, fully connectorized on both electrical and optical sides, and designed for rapid deployment.

Key technical specifications include:

- MT, TMT, or custom optical interfaces

- 4 transmit and 4 receive channels per unit

- High-density electrical interposer for seamless integration

- Conversion speeds of up to 25 Gbps per channel, compatible with XXXGBASE-XXXX

- 15 dB optical budget at 10 Gbps for reliable transmission

- Packaging tailored for aerospace, defense, and space applications

- Low power consumption and effective heat dissipation

Hybrid Connectivity with MT Ferrule in DMM Modules

A captive screw mechanism ensures quick and secure installation, even in vibrating environments. The module’s compact design is compatible with both round and flat cabling, making it suitable for space-limited settings. This DMM hybrid solution is particularly effective for aerospace, military, and advanced technology applications.

Custom Fiber Optic Assemblies for Optimal Integration

Available configurations include:

- Hybrid electrical and optical assemblies

- Optical harnesses with multiple channels, available in singlemode or multimode formats

- Custom connectors with reinforced cable terminations

- Integration into racks, housings, PCBs, or other mechanical assemblies

In-House Optical Testing and Validation

Nicomatic operates a dedicated laboratory for optical testing, ensuring comprehensive qualification of fiber optic links to meet industry standards. This includes measuring insertion loss (IL) and return loss (RL) to guarantee signal integrity.

The lab also conducts mechanical and thermal endurance tests to confirm reliability under demanding conditions. Functional testing is performed under various stress factors such as shock,vibration,and temperature,with data rate monitoring ranging from 1 to 25 Gbps per channel.

Additional procedures include microscopic inspections and cleanliness checks, and also geometry assessments of connector end faces to ensure proper alignment and finish. These services facilitate faster prototyping, enhanced reliability, and smoother transitions to production.

Technical Training in Fiber Optics

To promote consistent and compliant fiber optic assembly, Nicomatic offers hands-on technical training led by its experts. These sessions guide participants through the entire assembly and inspection process.

Training advantages include:

- Understanding of international standards such as IEC 61300

- Practical training on stripping, polishing, cleaning, and visual inspection

- Methods for maintaining optical budgets through quality control

- Structured inspection processes for reliable production

- exposure to a variety of fiber terminations (MT, PMT, ARINC 801, MIL)

- Optional certification upon course completion