Introducing Windform® RS: The Next Generation of Composite Materials

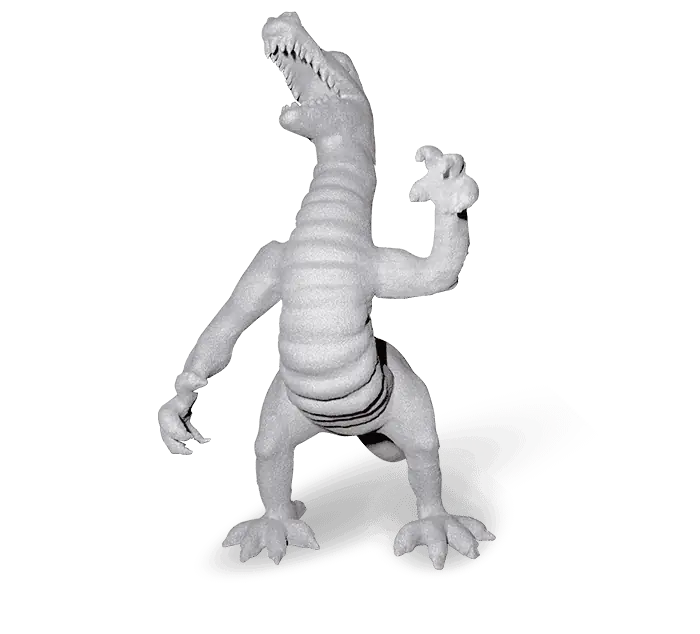

Windform® RS is an advanced composite material,specifically a carbon-fiber-reinforced polyamide,engineered by CRP Technology for cutting-edge Selective laser Sintering (SLS) applications. Designed for unmanned aerial vehicles (UAVs) that operate in harsh environments, windform® RS offers an impressive combination of strength, versatility, and resistance to both impact and environmental challenges. With a tensile strength reaching 85.25 MPa and an elongation at break of nearly 10%, this material provides the necessary rigidity and adaptability for drone structures, allowing them to endure vibrations, mechanical shocks, and extreme cold temperatures as low as -40°C without any degradation.

Remarkable Thermal and Environmental Resistance

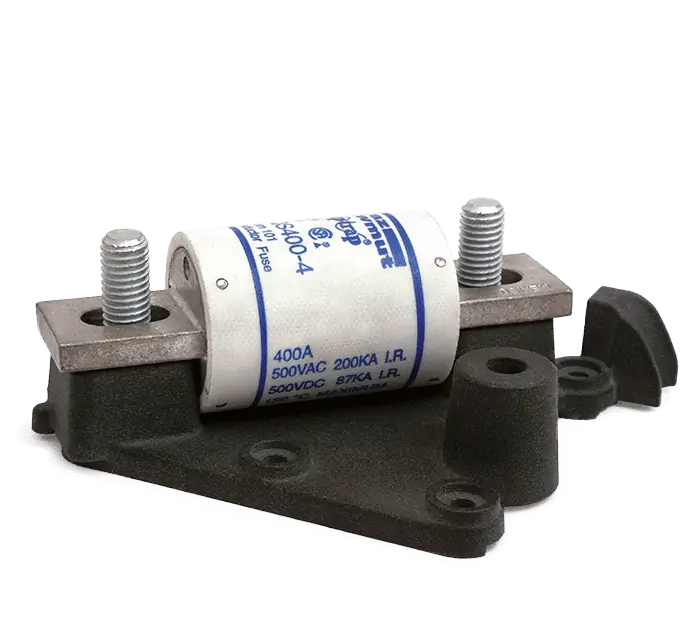

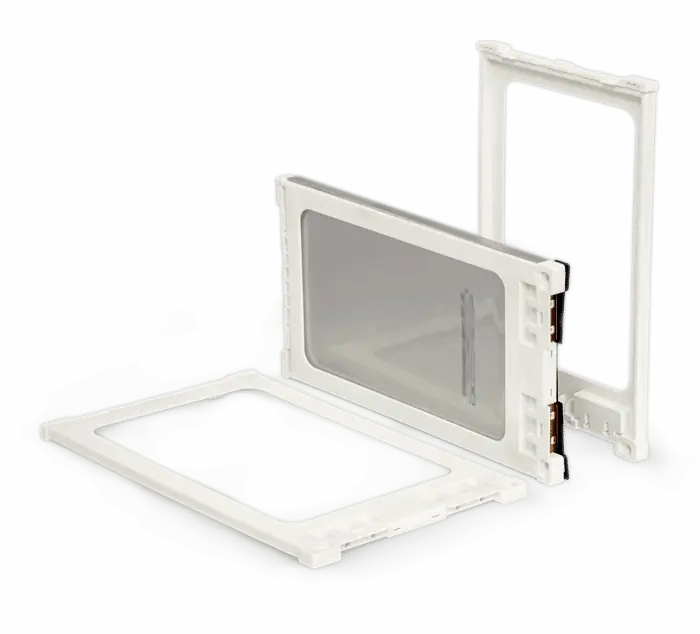

This robust thermoplastic features a heat deflection temperature (HDT) of approximately 192°C at 1.82 MPa, ensuring it remains stable even in high-temperature flight conditions. Its remarkable resistance to water and chemicals, effective with a mere 1 mm thickness, makes Windform® RS ideal for UAV systems that face exposure to rain, dust, and corrosive elements. Coupled with a lightweight density of 1.10 g/cc, this material is perfect for creating custom or pre-production components that meet aerospace standards. It is particularly advantageous for functional drone components, protective enclosures, mounting systems, and critical subsystems that require enduring mechanical strength and precise dimensional stability.