Flexrotor is a Group 2 vertical take-off and landing (VTOL) unmanned aerial system (UAS) that has demonstrated its effectiveness in both terrestrial and maritime operations. This compact, expeditionary, and highly autonomous system provides extended intelligence, surveillance, and reconnaissance (ISR) capabilities suitable for various civil and commercial uses.

With extensive flight experience, Flexrotor has been utilized in numerous demanding environments globally, making it the preferred choice for a diverse clientele, including government agencies, military forces, and commercial organizations.

Extended Flight Time with Minimal Logistics

The Flexrotor UAS offers an impressive flight duration of 12 to 14 hours in its standard configuration,making it a leader in range and endurance within its category. This expeditionary UAS is adept for both land and maritime operations, featuring fully autonomous capabilities during both VTOL and wing-borne flight phases.

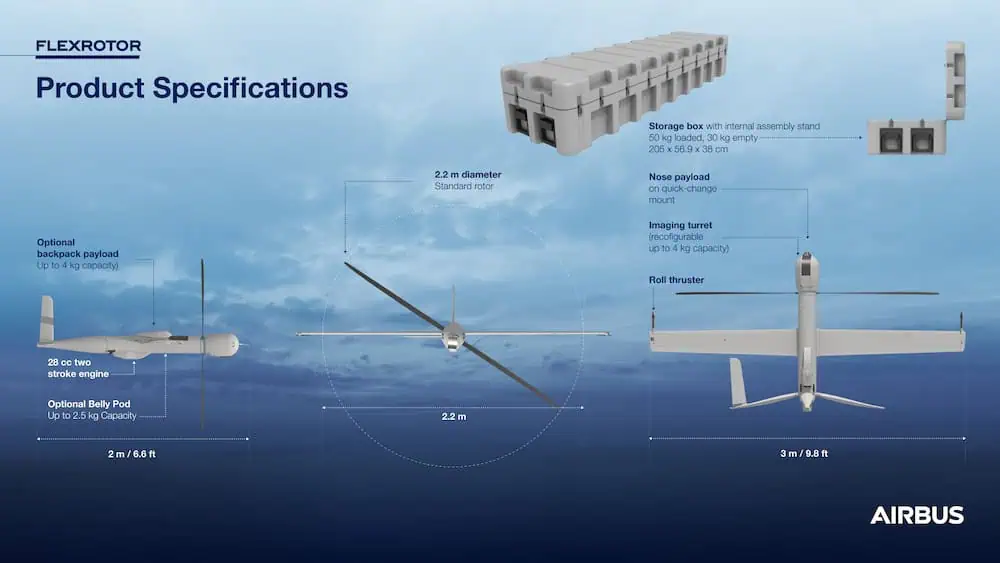

Due to its compact and modular design, Flexrotor is easily transportable and can be launched from a single vehicle or small craft. It can be fueled, assembled, and airborne in under 30 minutes, requiring no specialized launch and recovery equipment and only a 3.7 m × 3.7 m (12 ft × 12 ft) operational footprint.

Durable Design & Versatile Multi-Mission Capability

Flexrotor is built for robust, multi-mission functionality in some of the most demanding environments.It is designed to withstand wind gusts of up to 27 knots and has been tested in extreme temperatures and high altitudes, ensuring reliable performance in both land and maritime settings.

With a leading payload mass fraction and endurance among Group 2/3 UAS, Flexrotor provides outstanding operational efficiency—requiring less fuel, producing minimal noise, and reducing logistical demands. Its 28cc two-stroke engine can operate on either gasoline or heavy fuel, simplifying supply chain logistics.

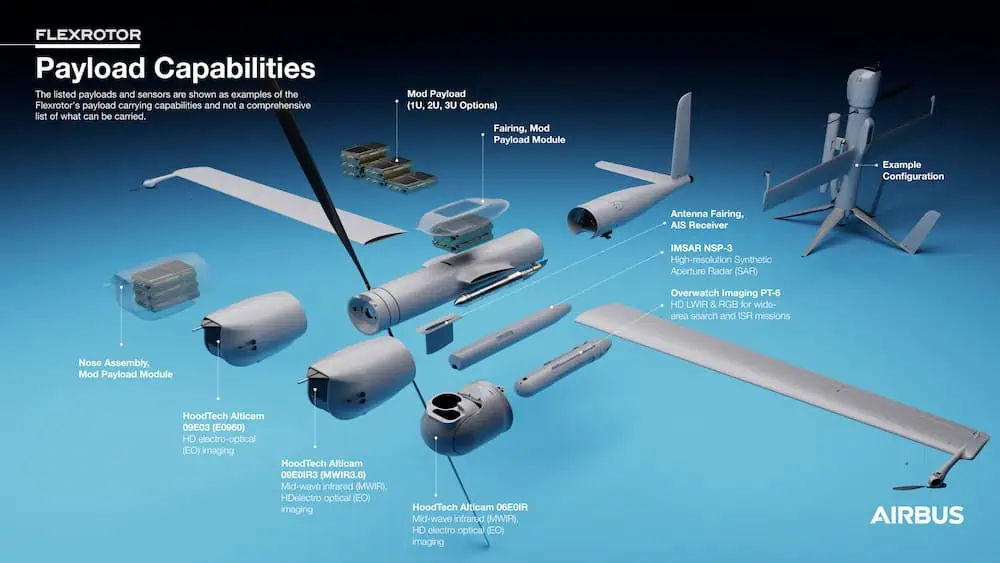

The aircraft supports easy integration with a variety of sensors, including EO/MWIR/LWIR cameras, SIGINT/ELINT systems, AIS, and wide-area search technologies. With an 8 kg payload capacity and compatibility with digital turrets and interchangeable sensor packages, Flexrotor is designed not only for current ISR missions but also for future advanced payloads.

Flexrotor Specifications and Features

Highlighted Features

- VTOL Launch & Recovery: Operates in confined 3.7 m × 3.7 m spaces (12 ft x 12 ft) without requiring a runway.

- Autonomous Operation: Fully automated from launch through VTOL and wing-borne flight phases.

- Typical Endurance: 12–14 hours (up to 30+ hours in optimized configurations).

- Payload Agnostic: Supports interchangeable payloads and digital turrets.

- Compact Design: Fits into a 50 kg case; easily transportable in a pickup truck or on a ship deck.

- Swift Assembly: Ready for launch in under 30 minutes.

- Efficient Performance: Combines helicopter-like thrust with the efficiency of a powered sailplane.

- Stealthy Operation: Inaudible at 500 m.

- Engine: 28 cc 2-stroke; compatible with gasoline and heavy fuel.

For further details, visit the Flexrotor Group 2 VTOL UAS page.

Operational Applications

land-Based ISTAR

Flexrotor provides military forces with a strategic advantage during critical operations such as intelligence collection, surveillance, and border security, enhancing situational awareness that leads to informed decision-making and successful mission execution.

maritime ISTAR

This adaptable UAS excels in maritime environments, offering long-endurance capabilities that ensure continuous surveillance over extensive water areas for naval operations, including fleet protection and coastal monitoring.

ELINT & SIGINT

Flexrotor can be outfitted with various ELINT and SIGINT systems, transforming it into a long-endurance, discreet data collection platform capable of detecting and tracking electronic signals and communications, providing essential insights for intelligence and electronic warfare operations.

Emergency Response

With its rapid deployment capabilities and versatile payload options, Flexrotor is perfectly suited for first response, firefighting, search and rescue, and disaster management tasks, delivering crucial aerial data that enhances the effectiveness of ground teams.

Infrastructure Surveillance

Flexrotor is also ideal for monitoring and inspecting extensive infrastructure and utility corridors, such as roads, railways, power lines, and pipelines, providing hours of endurance to accomplish more in a single flight.

Production & Support

Flexrotor is produced at Airbus facilities in Bingen, Washington, supported by a specialized team of UAS professionals. Leveraging Airbus’s extensive engineering capabilities and logistics network, the program benefits from robust design, precise manufacturing, and thorough lifecycle support to ensure operational readiness.

For detailed technical specifications, use cases, and current mission deployments, please visit the Airbus Flexrotor page.