Discover how Epoxy Resin (ER) conformal coatings from top manufacturers,including insights from Specialty Coating Systems (SCS),provide extraordinary protection for electronic devices in aerospace,defense,and industrial sectors.

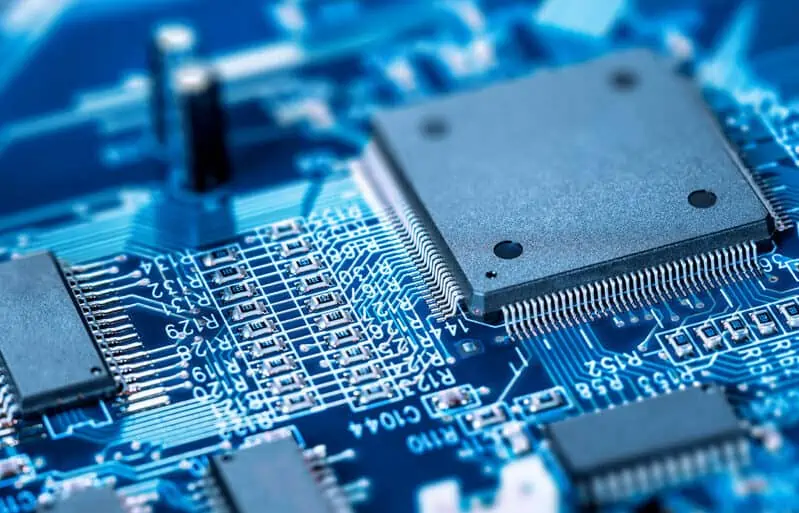

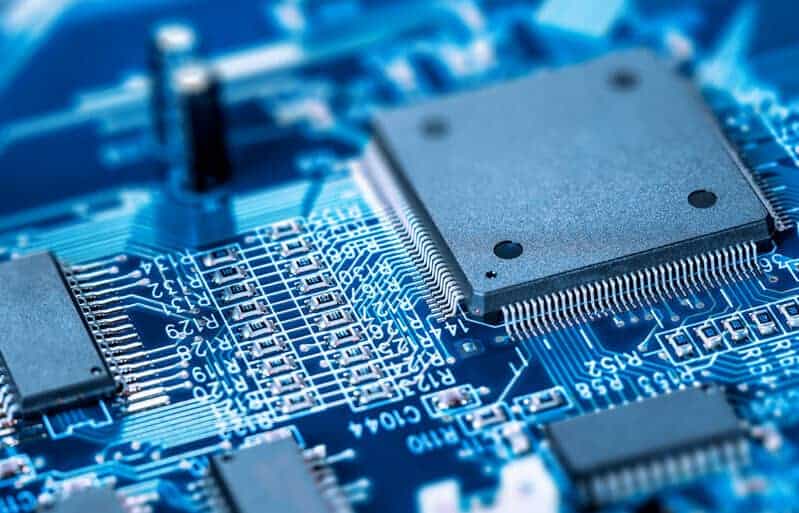

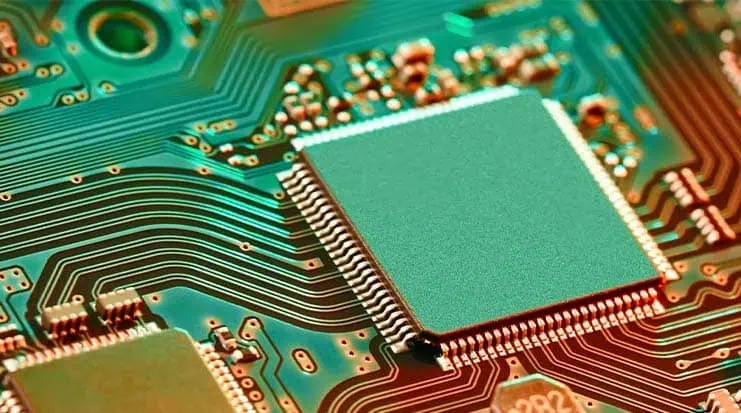

Epoxy Resin conformal coatings are widely recognized for their ability too safeguard electronic components in challenging environments, particularly within the defense, aerospace, and industrial electronics fields. These coatings offer remarkable resistance to moisture, chemicals, and physical wear, making them ideal for applications where durability and environmental safeguarding are paramount.

Notable epoxy coatings such as MG Chemicals 4225, HumiSeal® 2A53, and Henkel loctite® EC 210 are specifically designed to protect sensitive electronics and printed circuit boards from various environmental hazards. These coatings can be applied through manual or automated methods, including spray, brush, or dip techniques, creating a robust barrier that substantially enhances the lifespan and resilience of critical systems.

Additionally, epoxy coatings exhibit strong resistance to solvents, effectively hindering reverse engineering by concealing circuit designs and discouraging tampering. Though, these same characteristics can complicate rework or repairs compared to other types of conformal coatings. For projects that may necessitate frequent modifications, option coatings could be more appropriate, and manufacturers like SCS can provide valuable guidance during the selection process.

Whether your goal is to prolong the operational life of your electronics or comply with rigorous performance standards, epoxy conformal coatings present a high-performance solution.

Read the original article.