CRP Technology is a leader in certified 3D printing for the Aerospace and UAV (Unmanned Aerial Vehicle) industries. Their Windform® range of composite materials is specifically designed for these demanding applications. The extensive range of carbon and glass fiber Windform composites are lightweight yet high-strength, making them ideal for creating flight-ready components that can withstand the harsh conditions of aerospace and space environments.

Contact CRP Technology today for a free sample on your next aerospace project!

AS9100 & ISO 9001 Certified. Guaranteed Quality for your Aerospace & UAV projects.

CRP Facilities are not only certified to AS9100 (aerospace quality standards) and ISO9001 (international quality management standard), but these standards are also implemented with utmost rigor and enhanced by dedicated Quality Tracking software providing for real time process monitoring. This ensures every aspect of our operation, from manufacturing processes to management systems.

Dedicated FOD Prevention Area

Dedicated FOD Prevention Area

This dedicated space ensures a clean and safe environment to produce your critical components and to minimize the risk of contamination.

Boost Flight Time & Efficiency

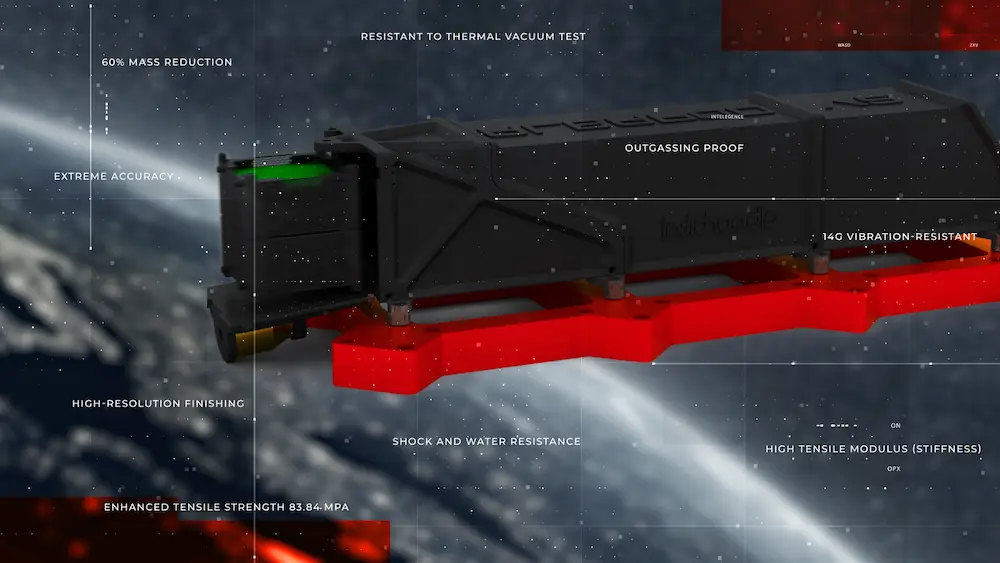

Carbon and Glass-fiber Windform® composites deliver the industry’s best weight-to-density ratio, resulting in drone components up to 60% lighter than those manufactured with traditional methods. This translates directly to extended flight times, increased payload capacity, and reduced fuel consumption for your UAV/UAS.

Leading the way in aerospace & UAV 3D printing

Windform® composites aren’t just light they’re tough and durable. Extensively tested in real-world aerospace applications, they can withstand extreme temperatures, chemicals, and high shock/vibration and 14G. UAV, Satellites and deployers manufactured in Windform are still operational in long lasting missions and let you dominate any harsh environment with confidence.

- 30+ Years of Experience: Pioneering additive manufacturing for aerospace and UAV applications.

- State-of-the-Art Technology: Advanced 3D printing systems and Windform® composite materials.

- Certified Quality: AS9100 & ISO 9001 certified for the highest quality standards.

- Comprehensive Person to Person Services

Consultancy in Design for Additive Manufacturing, Prototyping, Production, and Post-processing - Trusted by Industry Leaders

Main Aerospace Agencies, Aero and UAV Manufacturers - Global Reach: Serving customers worldwide with 3 production facilities in Europe, USA and UAE with dedicated support.

More information: SLS 3D printing for drone parts

Windform composite materials

The Windform family of composites includes a wide range of options, with a solution for almost any drone design requirement.

Low-density polyamide material with high stiffness and excellent heat resistance, ideal for UAV airframes and arms

Lightweight carbon-filled composite with high stiffness and strength and excellent impact resistance – ideal for heavy-duty and mission-critical components

Impact-resistant and waterproof material for demanding shock and vibration-heavy environments

Space-grade material with excellent strength and stiffness, suitable for both functional prototypes and production

Halogen-free flame-retardant composite with UL 94 V-0 and FAR 25.853 compliance

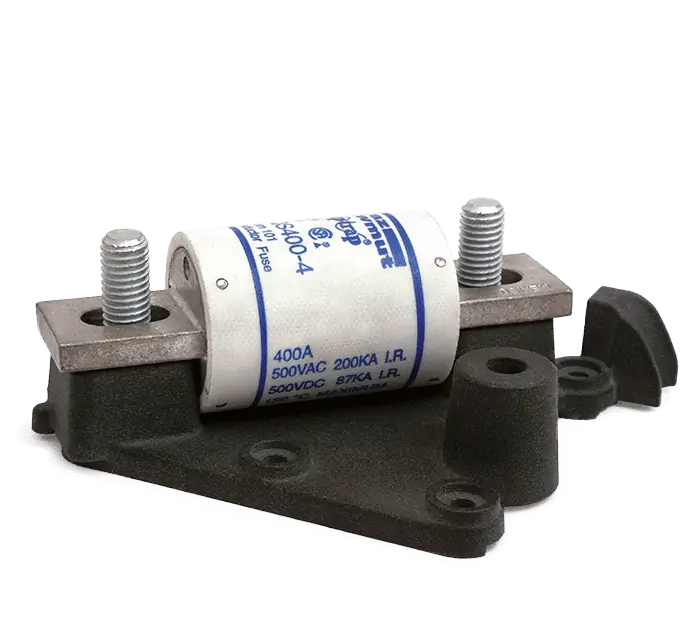

Glass fiber-filled flame-retardant composite with electrical insulation properties

Glass fiber-filled electrically insulated material with high flexibility and resistance to impact, shock and vibration

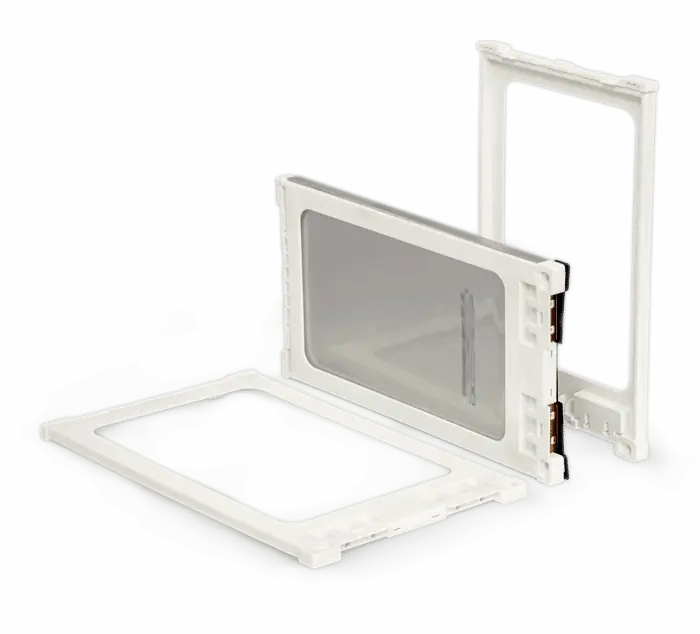

Next-generation glass fiber composite with excellent surface finish, ideal for components requiring aesthetic qualities

Rubber-like thermoplastic material resistant to repeated bending and torsion, with good shock absorption

Impact-resistant polyamide with behaviour similar to polypropylene and ABS injection moulded parts

Thermoplastic polyurethane material with excellent flexibility and shock absorption, ideal for robotics parts such as joints, pipes and connection tubes

Aluminium and glass fiber filled polyamide with excellent surface definition, suited to intake ducts and fuel systems

To find out more about which Windform material is right for your application, visit our product selector

Applications & Use Cases

Modular Drone Designs

Two carbon fiber reinforced thermoplastic composites, Windform SP and Windform XT 2.0, were used to create functional and critical parts of the Tundra flight-ready professional drone prototype. These parts – arms and body – are fully modular and were able to successfully withstand the design requirements, including space limitations and extreme conditions during flights, allowing for system optimization.

- Exceptional performance: Windform SP and XT 2.0, carbon fiber reinforced materials, offer superior strength, lightweight properties, and high thermal stability compared to traditional manufacturing methods.

- Design freedom: The modular design of the drone’s arms and body, allows for increased customization and optimization to meet specific missions and operations demands including different payload options.

- Durability under stress: Windform parts successfully withstood not only rigorous testing but also real life operations including space constraints and extreme flight conditions, demonstrating their reliability and suitability for demanding applications like professional drones.

Wind tunnel model of the Leonardo Tiltrotor AW609

Once assembled, these main components made with Windform underwent a series of dedicated low-speed wind tunnel tests, demonstrating high-performing mechanical and aerodynamic properties.

Unmanned Helicopter Tail Rotor Gearbox Housing

Orbital Rocket Propulsion Systems (Rocket motor system)

While we can only disclose a few real-world applications due to confidentiality concerns, there are a variety of existing application cases in the UAV-UAS, Aerospace and Avio industry where Windform is widely employed

Dedicated FOD Prevention Area

Dedicated FOD Prevention Area

Windform SL

Windform SL Windform RS

Windform RS Windform SP

Windform SP Windform XT 2.0

Windform XT 2.0 Windform FR1

Windform FR1 Windform FR2

Windform FR2 Windform GT

Windform GT Windform LX 3.0

Windform LX 3.0 Windform RL

Windform RL Windform FX Black

Windform FX Black Windform TPU

Windform TPU Windform GF

Windform GF