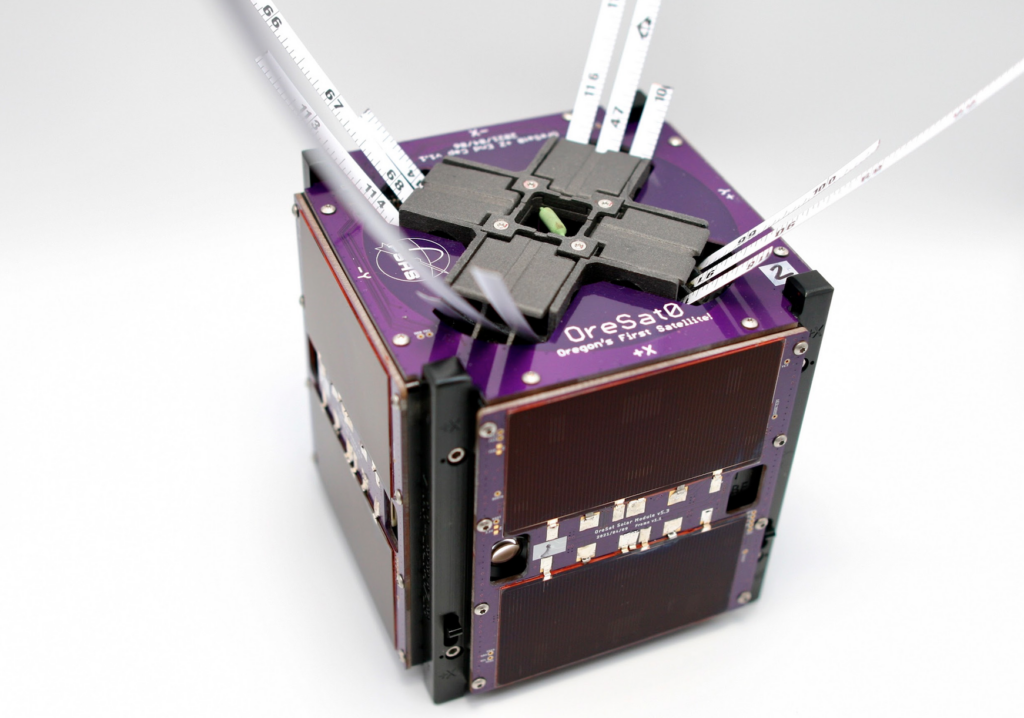

OreSat0

CRP Technology to Showcase Innovations at Space Tech Expo Europe 2024

CRP Technology is excited to announce its first appearance as an exhibitor at the upcoming Space Tech Expo Europe 2024.

Event Details and Location

This significant event in the aerospace calendar is scheduled for November 19–21 in Bremen, Germany. Attendees are encouraged to visit CRP Technology at Booth B54 to discover state-of-the-art 3D printed innovations.

Showcasing Advanced 3D Printed Solutions

At the expo, CRP Technology will present high-performance components crafted for leading industry clients, utilizing their acclaimed Carbon and Glass fiber-reinforced Windform composite materials. These components are produced through Selective Laser Sintering (SLS) 3D printing technology, ensuring they meet the rigorous demands of the aerospace sector.

Lightweight and Durable Components for Space Missions

Visitors will have the possibility to explore a variety of 3D printed structural elements that are both lightweight and durable, making them suitable for manned and unmanned space missions. The display will include drone components, such as frames and aerodynamic structures designed for high-performance UAVs, alongside space-grade prototypes for satellites and exploration missions, showcasing the precision and durability of the SLS process combined with Windform materials.

Stringent Testing for Aerospace Standards

Windform materials undergo extensive testing to comply with aerospace industry standards. These evaluations include assessments for outgassing to ensure vacuum stability, thermal resistance to handle temperature fluctuations, and UV stability for prolonged sunlight exposure—critical for space applications. Additionally, Windform materials are resistant to chemical exposure and mechanical wear, while their dielectric properties provide essential insulation for sensitive electronics in satellite and dialog systems.

Enhanced Surface Quality with Advanced techniques

attendees at the CRP Technology booth will also witness the latest enhancement in CRP’s post-processing capabilities: vapor smoothing. This innovative technique improves the surface quality of Windform parts, making them smoother and more resilient against environmental challenges, thereby boosting performance in extreme conditions. When paired with manual finishing, CRP Technology’s globally recognized process yields outstanding results.

Precision CNC Machining for Superior Components

In addition to 3D printing, CRP Technology provides CNC machining services to refine windform components, ensuring precise tolerances, dimensional accuracy, and superior surface finishes. manual finishing techniques are also employed to enhance both the aesthetic and functional aspects of parts, catering to the specific requirements of the aerospace industry.

A Leader in Additive manufacturing

As a trailblazer in additive manufacturing, CRP Technology has significantly contributed to numerous successful aerospace initiatives.This expo presents a unique platform for engineers, designers, and decision-makers to experience how Windform materials can enhance production capabilities and expedite innovation cycles.

Join Us at Space Tech Expo Europe 2024

We invite you to visit CRP Technology at Booth B54 during Space Tech Expo Europe 2024 to explore the future of space technology.Our team of experts will be on hand to discuss tailored solutions for aerospace challenges,offering insights on material selection,design optimization,and rapid prototyping.

Discover companies specializing in 3D Prototyping & Additive Manufacturing Services > >