CRP Technology Introduces Windform SL: A New Era in 3D Printing Materials

CRP Technology, a leader in the 3D printing sector and a dedicated service bureau, has launched Windform SL, the twelfth entry in its renowned Windform TOP-LINE series.

Innovative Composition and Properties

Windform SL is a cutting-edge composite made from polyamide and reinforced with carbon fibers. This material is designed to be exceptionally lightweight, featuring a density of just 0.87 g/cc,which contributes to its ultra-light and rigid nature.

A Milestone in Additive Manufacturing

In the fast-paced world of additive manufacturing, the introduction of windform SL represents a significant advancement for professional 3D printing using Powder Bed Fusion and Selective Laser Sintering techniques.As the latest addition to the esteemed Windform TOP-LINE collection, windform SL is poised to make a substantial impact in the AM landscape.

Commitment to Innovation

The launch of Windform SL follows closely on the heels of CRP Technology’s introduction of Windform TPU, the company’s second elastomeric material, reinforcing its dedication to innovation in 3D printing.

Franco Cevolini, the CEO and Technical Director of CRP Technology, stated: “our dedication to progress is unwavering. As a pioneering entity in the industry, we continuously strive to develop top-tier materials for professional 3D printing. Windform SL exemplifies our ongoing journey of growth and innovation, ensuring we remain at the forefront of the sector.I am confident that this material will quickly become the preferred choice for many UAV and automotive clients who depend on our 3D printing services for their advanced components.”

Applications and Performance

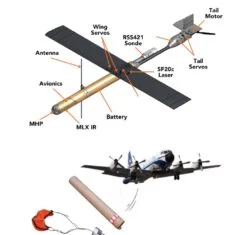

Windform SL is particularly favorable for creating functional prototypes and components within the UAV/UAS industry,as well as in applications that require a combination of lightness,rigidity,and thermal stability.

Key features of Windform SL include a Heat Deflection Temperature (HDT) at 1.82 mpa of 182.5 °C, along with notable values for Specific Tensile Modulus, Specific Tensile Strength, and Impact Strength (Charpy and Izod). These attributes enable the material to maintain structural integrity under significant stress, even at elevated temperatures, ensuring dependable performance in challenging conditions.

Exceptional Surface Finish

The post-processing surface quality of Windform SL is also remarkable, achieving Ra values of 5.44 µm after the SLS process, 1.56 µm following manual finishing, and 0.83 µm post-CNC processing, resulting in smooth and precise surfaces.

Transforming the Future of 3D Printing

Windform SL is not merely a new material; it represents a elegant solution for the future of professional 3D printing. With extensive applications in the UAV sector and beyond, Windform SL is set to transform the production of advanced and efficient components across various industries, including aerospace and automotive, all while maintaining lightweight properties without compromising thickness.