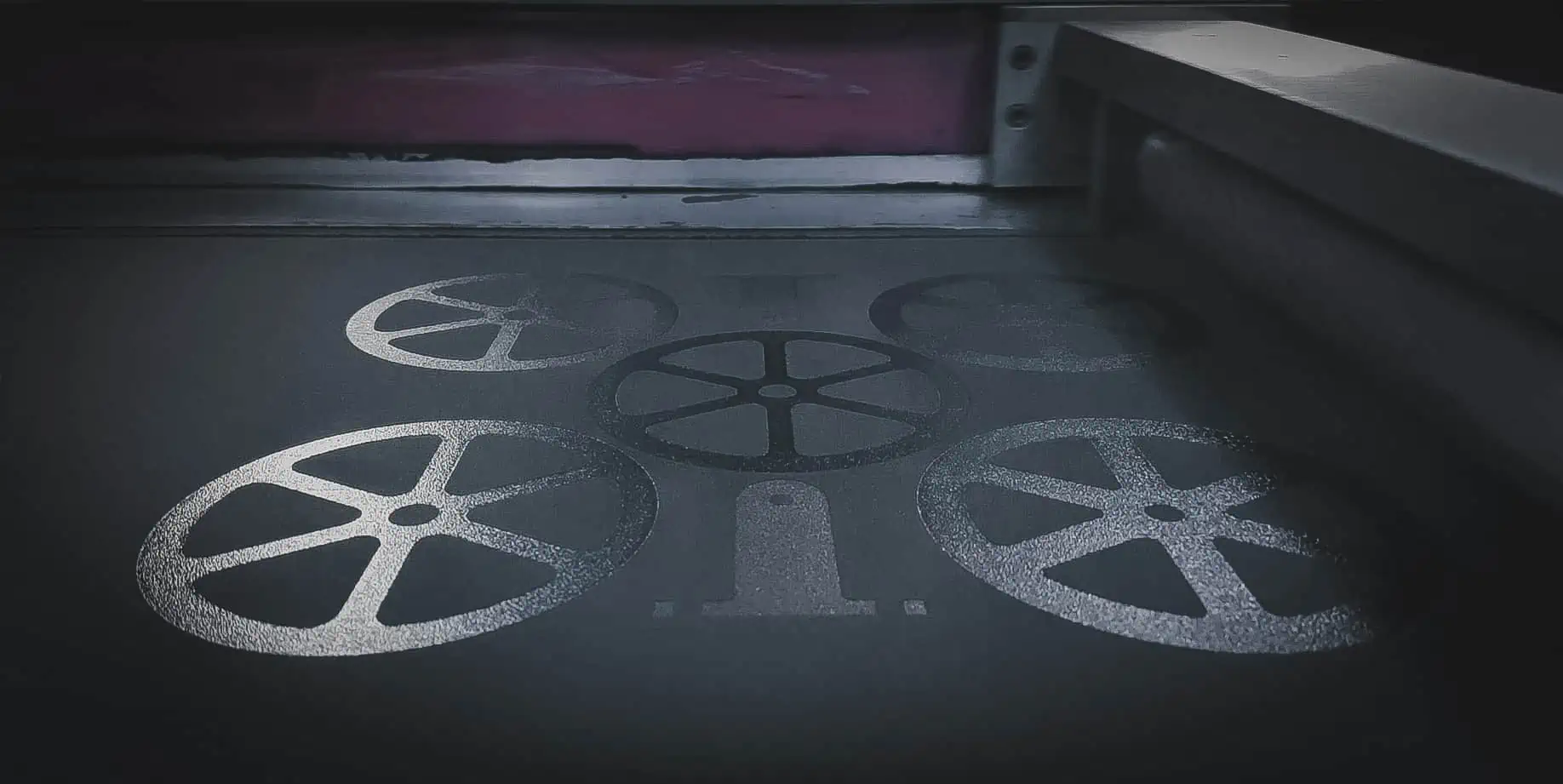

Innovative 3D Printing for Unmanned Aerial Systems

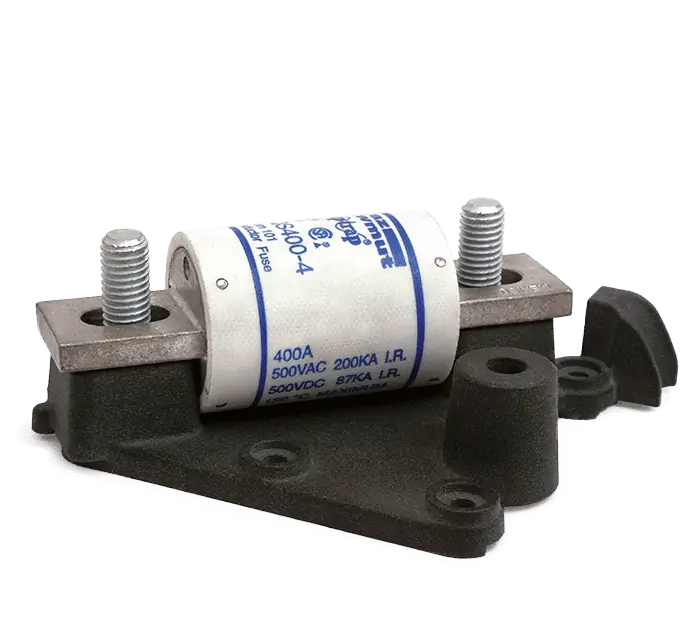

CRP Technology has unveiled a detailed case study highlighting its role in the advancement of Flying-Cam’s latest unmanned aerial vehicle (UAV),known as Finding. The company was tasked with producing the tail rotor gearbox housing, a crucial component attached to the main tail boom.

objective: Lightweight and Durable Design

The primary goal was to engineer a housing that is both lightweight and robust, providing essential physical and aerodynamic protection for the tail rotor actuators and GPS antenna of the Discovery helicopter.

Advanced Manufacturing Techniques

In alignment with FLYING-CAM’s specifications, CRP Technology chose to utilize a 3D printing method involving composite polymer materials, specifically through Powder Bed Fusion (PBF) using Selective Laser Sintering. The material selected for this project was Windform® XT 2.0.

Material properties and Applications

Windform XT 2.0 is a carbon fiber-reinforced polyamide composite, ideal for high-performance applications in sectors such as motorsports, aerospace, and unmanned aerial vehicles. Its mechanical and thermal characteristics are intricately linked to the 3D printing process, resulting in exceptional, technologically advanced components that are ready for immediate use.

Further Insights

For a extensive understanding of this project, read the complete case study or explore more on the CRP Technology website.