Flyber stands at the forefront of developing and producing both standard and precision-engineered propeller solutions tailored for UAVs (unmanned aerial vehicles). Crafted from cutting-edge carbon fiber composites, our offerings are engineered to deliver exceptional aerodynamic efficiency, durability, and weight reduction without compromise. Each product can be customized to meet the specific needs of your aircraft and its operational demands.

Our manufacturing operations are based in the UK and Europe, which enhances supply chain resilience and reduces dependency on geopolitically sensitive areas. This strategic positioning allows us to provide quicker turnaround times, lower costs, and unmatched reliability, ensuring our clients receive the components they need promptly and efficiently.

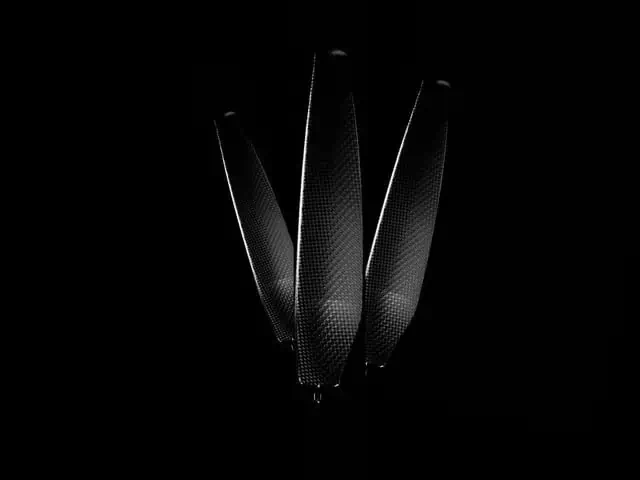

UAV Propeller Solutions

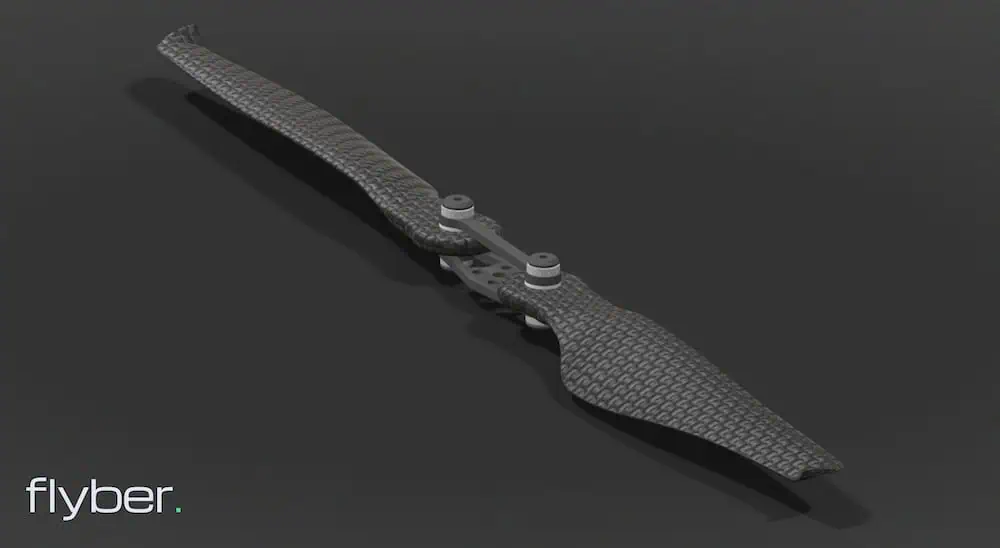

Our standard drone propellers are perfect for a variety of applications, such as inspections, cargo transport, precision farming, and defense operations.Designed for aerodynamic efficiency and minimal noise, our durable products are built to endure the demands of daily use in challenging environments.

We can rapidly scale production to meet the demands of drone fleets of any size, ensuring swift delivery. Each product undergoes extensive testing and validation in accordance with various aerospace, defense, and regulatory standards. We are also pursuing ISO 9001 and Cyber Essentials certifications as part of our commitment to quality and security.

Our UAV propellers come in diameters ranging from 10 to 36 inches, with multiple material options available.

Discover more: UAV Propeller Solutions

Custom Propeller Design and Manufacturing

for specialized needs that exceed the capabilities of standard products, we offer fully custom propellers designed specifically for your mission,UAV structure,or acoustic requirements. Our skilled engineers collaborate closely with you to identify and address your needs, integration challenges, and real-world flight conditions, ensuring an optimal solution for any application.

We manage the entire front-end engineering process internally, adhering to a stringent development workflow:

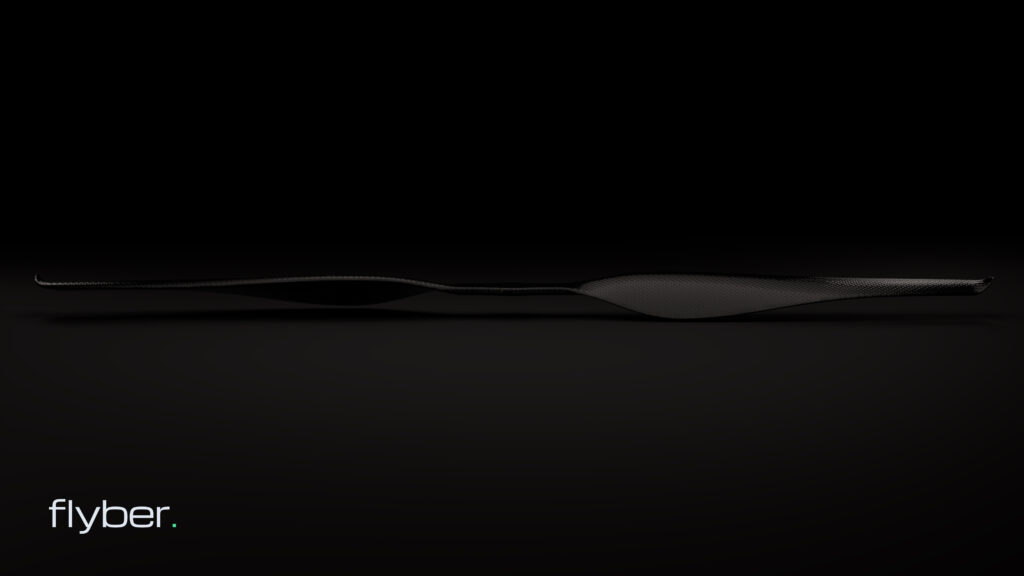

- Design – Utilizing aerospace-grade CAD and Design for Manufacturing (DfM) principles, we optimize rotor geometries and structural configurations for weight, aerodynamics, and manufacturability.

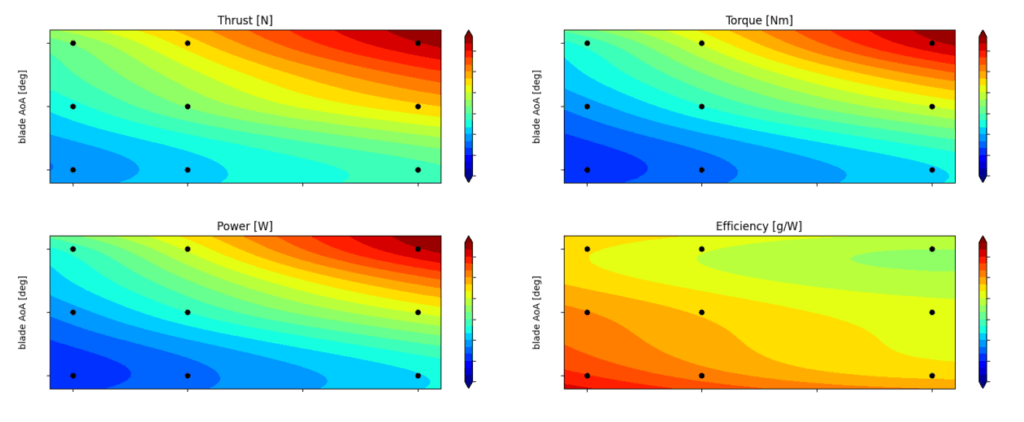

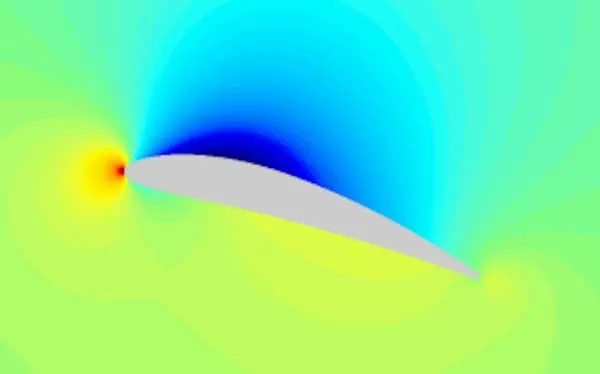

- simulation – Blade designs are tested and refined under dynamic conditions, employing Computational Fluid Dynamics (CFD), load modeling, and actual flight data to accurately forecast thrust, drag, and noise levels.

- Advanced Composite Materials – All blades are constructed from high-performance carbon fiber composites, ensuring strength, rigidity, and lightweight properties capable of withstanding demanding UAV and Urban Air Mobility (UAM) environments.

- Manufacturing – Our proprietary manufacturing and quality assurance processes integrate digitally-controlled production with aerospace-grade traceability, guaranteeing that each blade meets or surpasses our stringent standards and your mission specifications.