Dymax stands at the forefront of producing UV/LED light-curable materials tailored for UAV/UAS satellites, missiles, and spacecraft.

Rapid-curing materials effectively bond and safeguard printed circuit boards (PCBs), electronic subassemblies, and optical components in critical aerospace, defense, and military operations, both manned and unmanned. These adhesives, coatings, and PCB maskants provide essential protection against moisture, chemicals, extreme temperatures, and other environmental factors that could jeopardize system integrity.

Eco-pleasant, single-component materials are engineered for diverse applications, including:

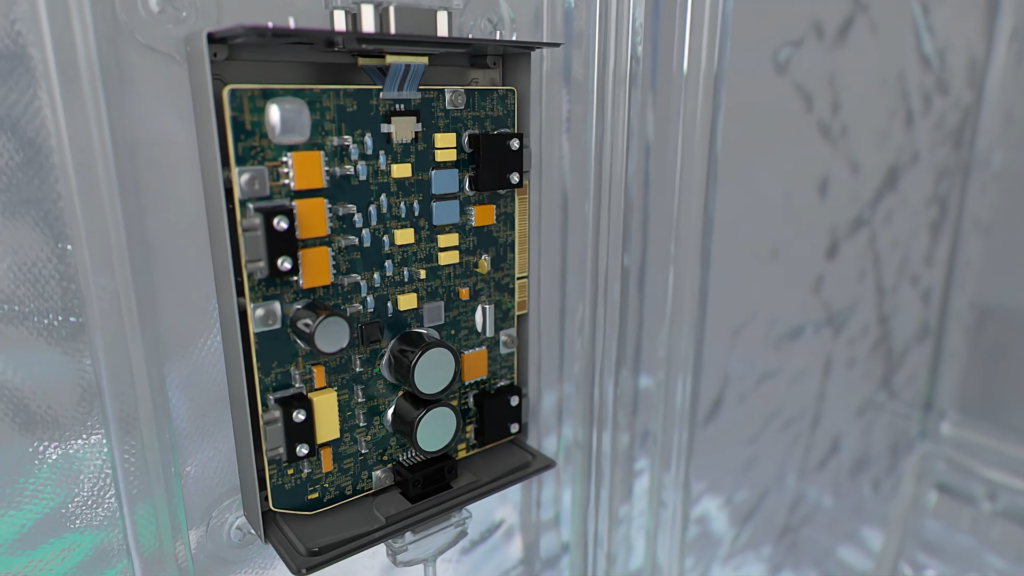

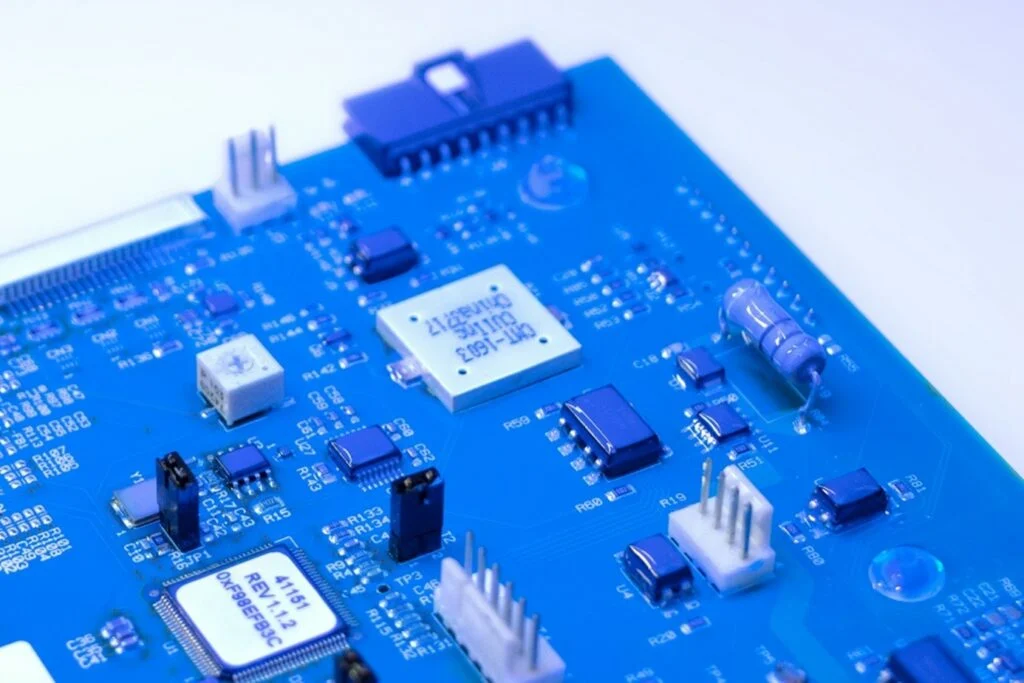

- Protection of PCBs and electronic components

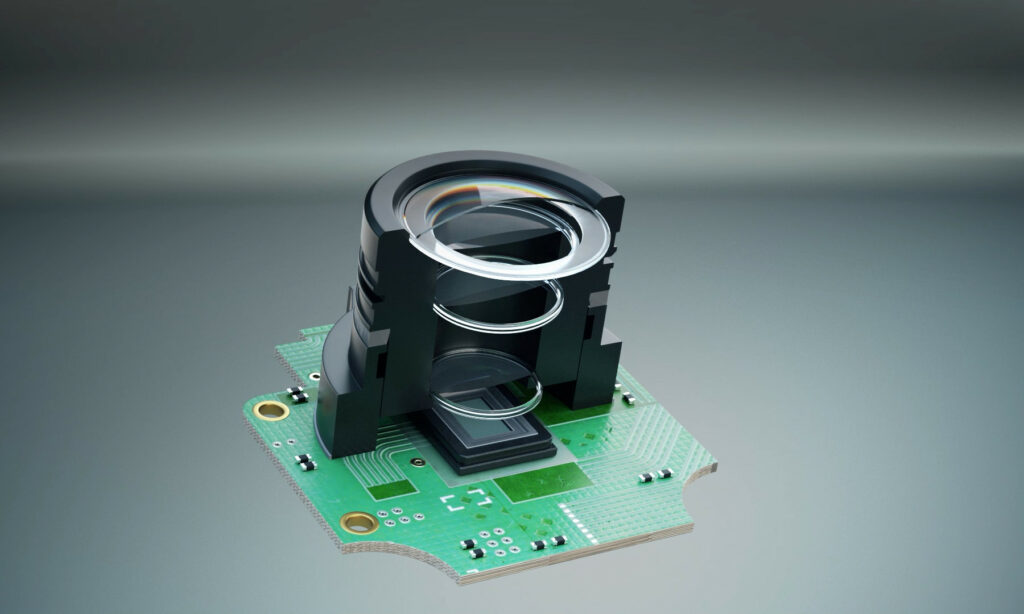

- Optical bonding, assembly of camera modules, and precise lens alignment

- Conformal coating masking of surfaces prior to finishing processes

Navigate to Section:

- Light-Curable PCB Conformal Coatings

- Light-Curable Adhesives

- Light-Curable Masking Materials for PCBs & Electronics

Light-Curable Conformal coatings

Dependable Protection for PCBs and Electronics

Dymax conformal coatings offer robust protection for substrates and component surfaces against the harsh conditions that PCBs often encounter. These coatings are solvent-free and cure in mere seconds under UV/Visible or LED light, enhancing process efficiency and reducing manufacturing costs.

Engineered for superior shielding, these UV-cured conformal coatings defend electronic PCBs and board-level components from moisture, dust, corrosion, and other adverse environments.Formulations with secondary heat-cure capabilities are available for applications with shadowed areas.

Bondable substrates include PCB materials, glass, FR-4, metal, ceramic, and glass-filled epoxy. Materials that comply with NASA’s ASTM E595 low outgassing standards for space applications, along with various IPC and MIL-spec approvals, are also available.

For further details: Light-curable conformal Coatings >

UV Assembly Adhesives

Optical Adhesives and Epoxies for Camera Module Assembly and Active Alignment

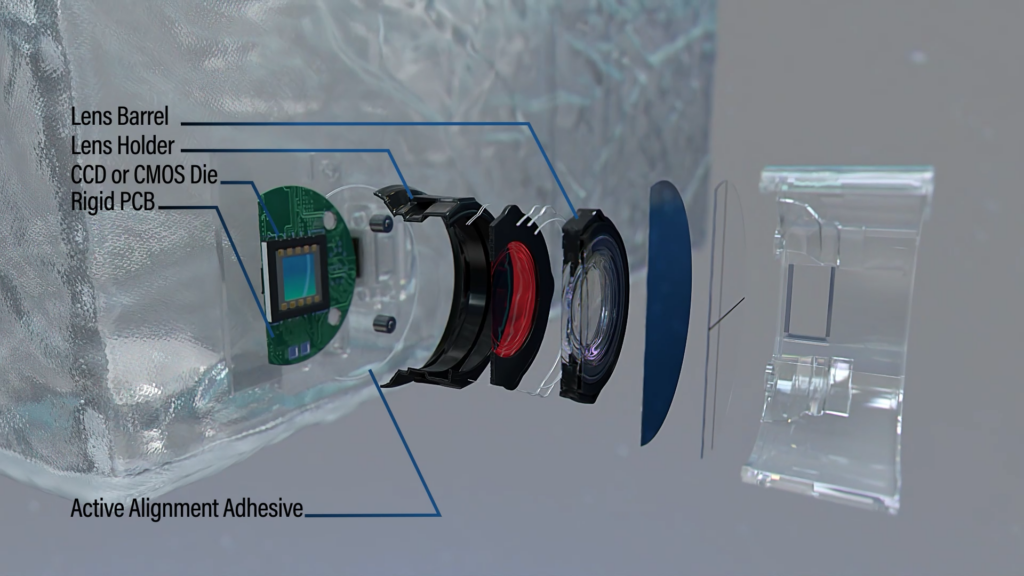

Dymax assembly adhesives cure rapidly under UV/Visible light, facilitating the swift and accurate assembly of optical components and camera modules. These adhesives are ideal for bonding lens barrels, holders, CCD or CMOS dies, and rigid PCBs, as well as for active alignment tasks.

These UV/LED cure epoxies are resistant to moisture and thermal cycling, meeting stringent low-shrinkage and low-outgassing standards required for satellite and spacecraft avionics. options with secondary heat-cure functionality are available to ensure complete curing in shadowed PCB areas.Bondable substrates include LCP, PCB, PPS, FPC, and metallic surfaces.

For more information: Light-Curable Assembly Adhesives >

SpeedMask® Maskants

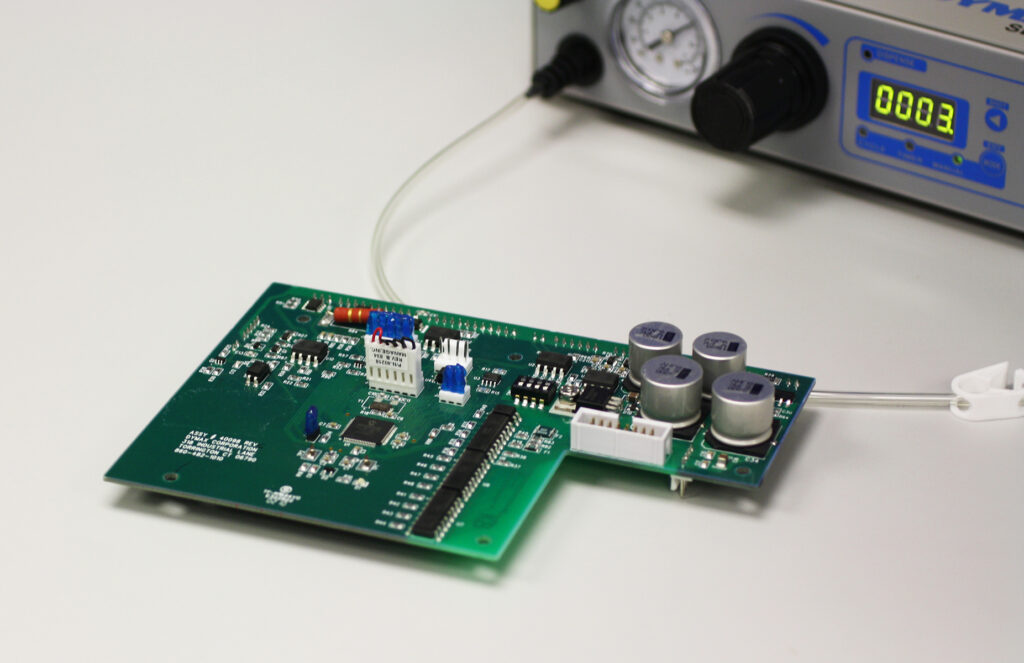

Protective Masking Materials for Conformal Coatings

Dymax SpeedMask maskants address various challenges in PCB and electronics manufacturing, particularly in protecting components during conformal coating masking processes. These materials adapt to intricate geometries and cure quickly when exposed to UV/Visible light, replacing customary slow-curing, labor-intensive methods like wax, tape, and lacquer masking. The PCB maskants are compatible with gold and copper pins, safeguarding keep-out areas during processing.

SpeedMask maskants can be applied through dipping, spraying, or screen printing in a single layer, making them ready for production instantly. They can be easily removed after curing by peeling,leaving a clean surface without residue or contamination. Moreover, they are an eco-friendly, solvent-free, single-component alternative to conventional two-part solvent-based maskants.

For additional details: SpeedMask Maskants for PCBs & Electronics >