This article explores the innovative technology behind acrylate and epoxy light-curable formulations utilized in critical aerospace and defense sectors, as presented by Dymax, a prominent producer of UV/LED light-curable materials.

Initially developed in the 1960s, ultraviolet (UV) light-curing technology emerged as a viable choice to conventional solvent-based methods, heat-drying processes, and slow-curing adhesives like silicones and epoxies. Though, it gained notable traction in industrial manufacturing by the early 1980s.

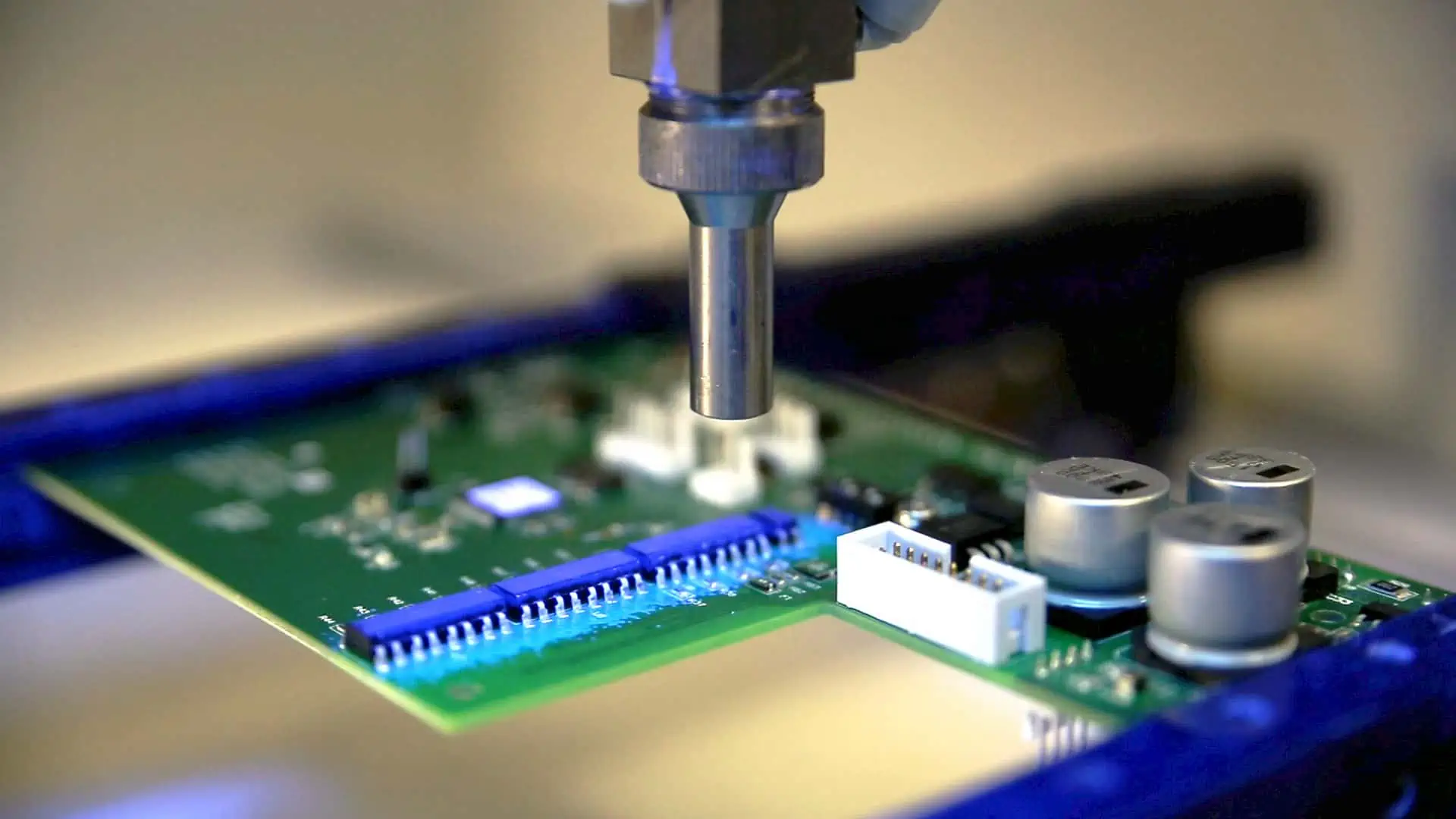

Today, this technology is extensively utilized across various sectors, including automotive, consumer electronics, telecommunications, medical devices, military applications, and graphic arts, due to its numerous advantages over conventional materials.

Over the past four decades, while the materials have advanced, the fundamental chemistries of acrylates and epoxies have remained consistent.

Acrylate Systems: Versatile and efficient

The term “acrylate” encompasses a diverse array of materials, including acrylates, methacrylates, and related functional groups.These systems react to UVA light and, in many cases, visible light, showcasing a wide spectrum of properties.

With the addition of various additives, acrylate systems can be tailored to be colored (such as red, blue, or black), opaque, fluorescing (often essential for in-line inspections), or thermally conductive. Key physical properties include adhesion,viscosity,durometer,and visual appearance. The ability to cure with visible light makes fluorescing and colored formulations particularly common.

The curing speed of acrylate resins is influenced by the specific formulation and the intensity of the light used, typically ranging from 0.5 to 15 seconds. The depth of cure varies based on the formula and process, generally falling between 0.10 in and 0.59 in (2.5 mm to 15 mm).

Acrylate light-curable materials (lcms) can also be designed to react to heat or activators, which is beneficial in situations where light cannot penetrate due to shadows. However, these materials typically do not cure in the presence of moisture or air.

Surface tackiness can sometimes occur with acrylate LCMs, caused by atmospheric oxygen interfering with the free radical curing mechanism. This tack can often be mitigated by adjusting the curing process, such as increasing light intensity or extending cure time. However, some acrylate LCMs are inherently tacky and are intended for applications where they are not exposed to air, such as in bonding two substrates together.

Epoxy (Cationic) Systems: Reliable and Strong

Epoxy LCMs, often referred to as “cationic systems” due to the type of photoinitiator used, represent the second major category of light-curable materials. While the range of properties achievable with these products is somewhat narrower than that of acrylate LCMs, they offer distinct advantages, including tack-free cures (eliminating oxygen inhibition) and enhanced adhesion to specific substrates.

One notable difference between epoxy and acrylate LCMs is that achieving full properties in light-curable epoxies often requires more time, leading to the use of heat to expedite the curing process. Additionally, the curing of cationic LCMs can be hindered by moisture and humidity.

UV curing enhances production efficiency, increases throughput, reduces work-in-progress and scrap rates, facilitates 100% in-line inspection, and, being a solvent-free process, minimizes environmental impact.