Dymax is a leading manufacturer of UV/LED light-curable materials for UAV / UAS satellites, missiles, and spacecraft.

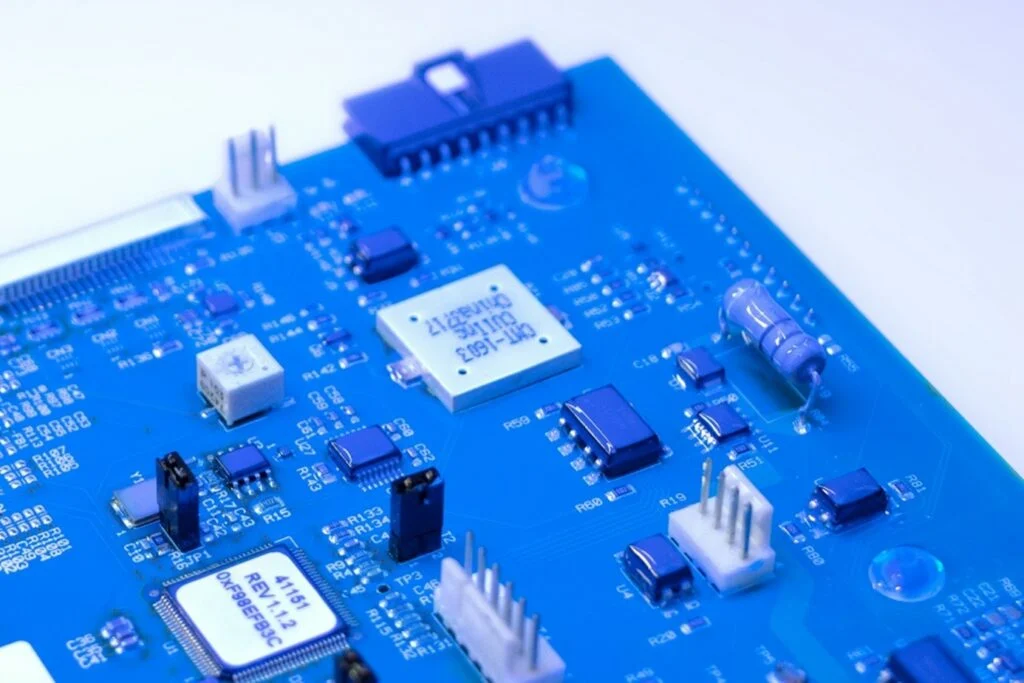

Fast light-curing materials bond and protect printed circuit boards, electronic subassemblies, and optical components in mission-critical manned and unmanned aerospace, defense, and military applications. These electronics assembly adhesives, coatings, and PCB maskants shield parts from moisture, chemicals, temperature extremes, and other environmental conditions that can cause systems to fail.

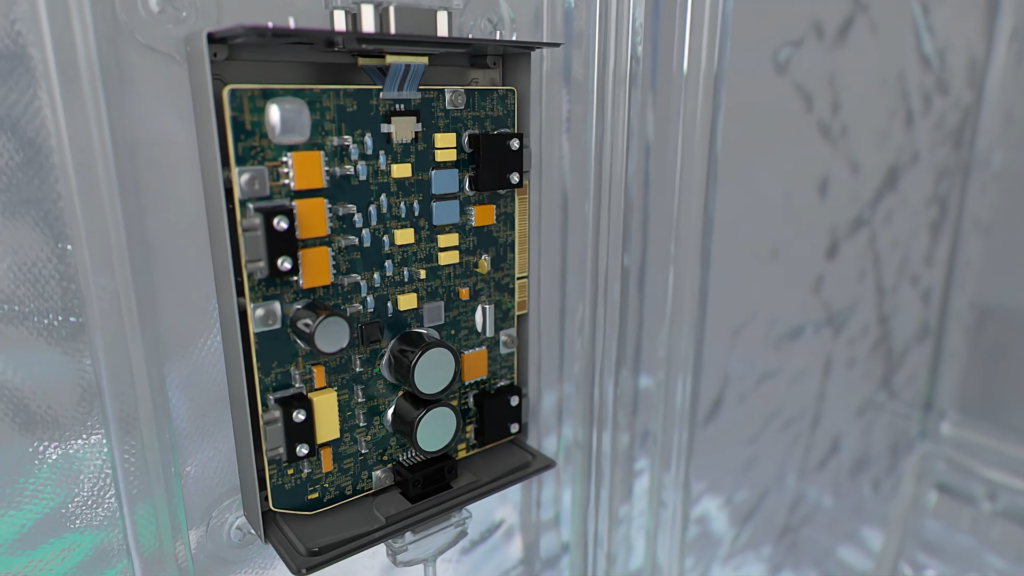

- Protection of PCBs and electronics

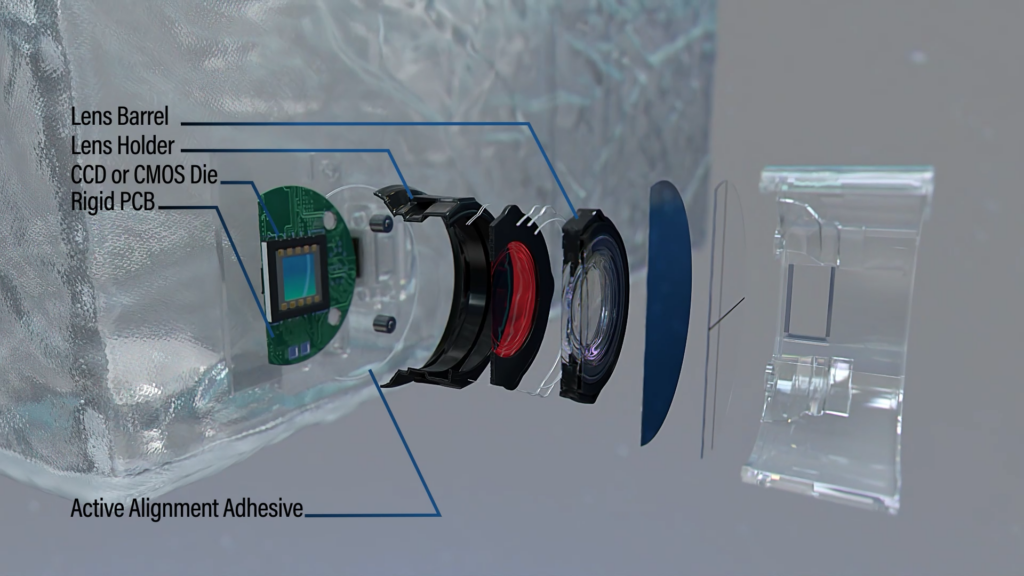

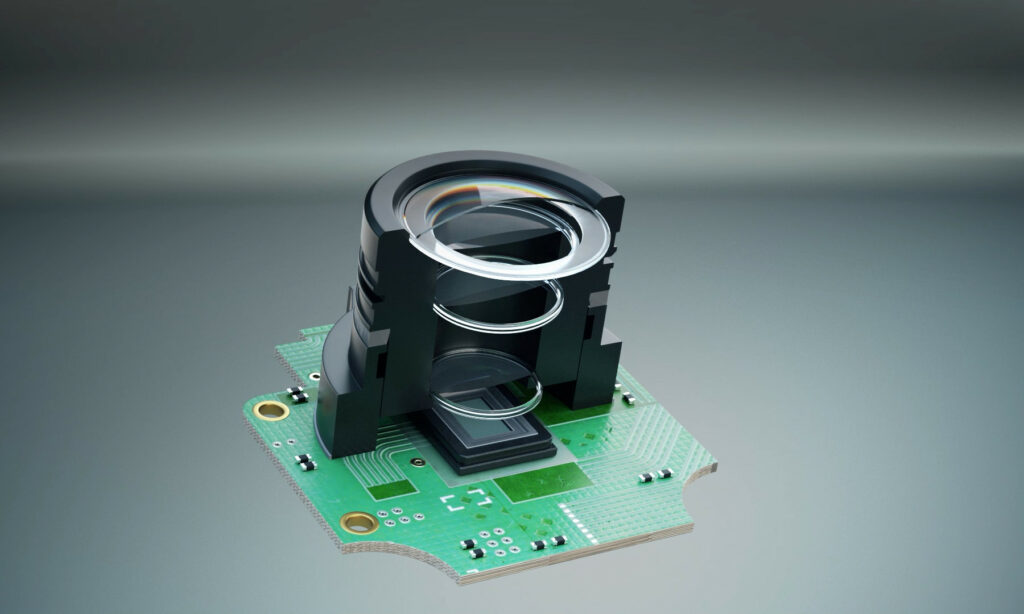

- Optical bonding, camera module assembly, and active alignment of lenses

- Conformal coating masking of surfaces prior to finishing processes

- Light-Curable PCB Conformal Coatings

- Light-Curable Adhesives

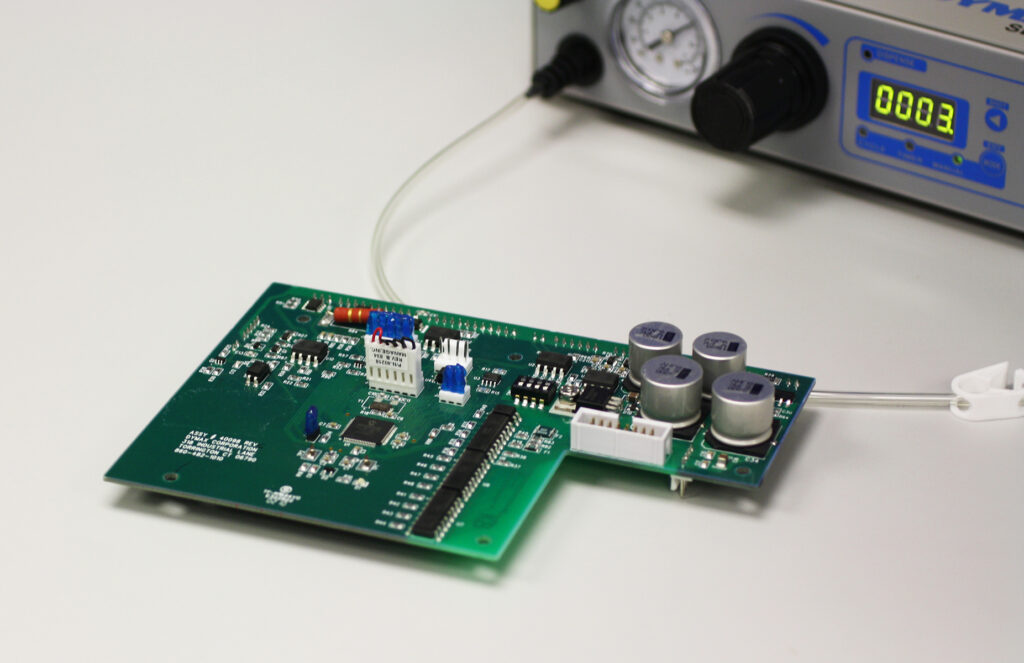

- Light-Curable Masking Materials for PCBs & Electronics

Light-Curable Conformal Coatings

Reliable Protection of Printed Circuit Boards and Electronics

Designed to provide enhanced shielding, the UV cure conformal coatings protect electronic PCBs and board-level components from moisture, dust, corrosion, and other challenging environments. Formulations with secondary heat-cure capability are available for applications where shadow areas exist.

Bondable substrates include PCB materials, glass, FR-4, metal, ceramic, and glass-filled epoxy. Materials that meet NASA’s ASTM E595 low outgassing requirements for space applications and numerous other IPC and MIL-spec approvals are available.

More information: Light-Curable Conformal Coatings >

UV Assembly Adhesives

Optical Adhesives and Epoxies for Active Alignment and Camera Module Assembly

Dymax assembly adhesives cure with UV/Visible light in seconds for rapid, precise assembly of optical component and camera module bonding. Assemble lens barrels and holders, CCD or CMOS die, rigid PCBs, or use them for active alignment applications.

These moisture and thermal-cycle-resistant UV/LED cure epoxies meet the stringent low-shrinkage and low-outgassing requirements for satellite and spacecraft avionics. Materials with a secondary heat-cure function are available to ensure a complete cure in PCB areas shadowed by light. Bondable substrates include LCP, PCB, PPS, FPC, and metallic surfaces.

More information: Light-Curable Assembly Adhesives >

SpeedMask® Maskants

Protective Conformal Coating Masking Materials

SpeedMask maskants can be dipped, sprayed, or screen printed in one layer, making them instantly production-ready. They are easily removed after proper cure via peeling, leaving a residue-free surface with no contamination. Additionally, they are a green, eco-friendly, solvent-free, one-component alternative to two-part solvent-based maskants.

More information: SpeedMask Maskants for PCBs & Electronics >