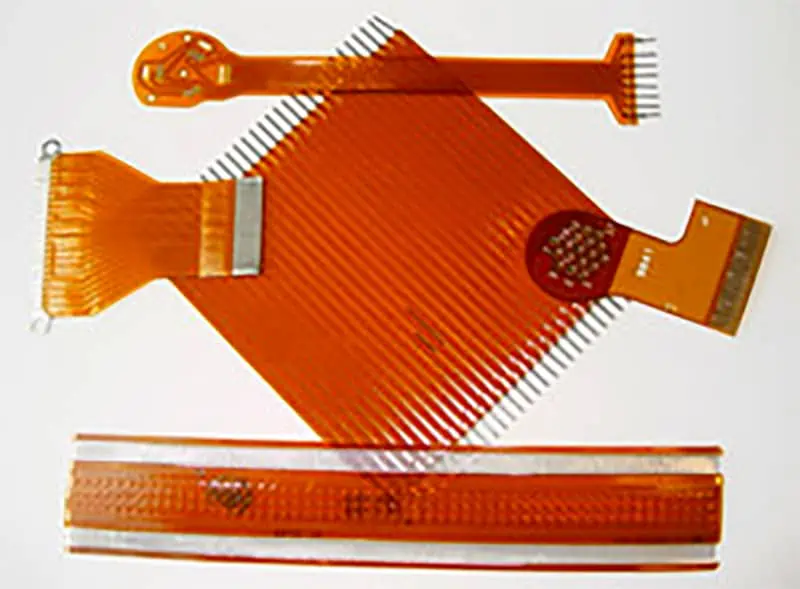

San Francisco Circuits stands at the forefront of PCB manufacturing adn assembly, offering innovative solutions to meet the industry’s dynamic challenges, especially in the realm of through-hole component assembly were conventional methods like wave soldering and hand soldering often fall short.

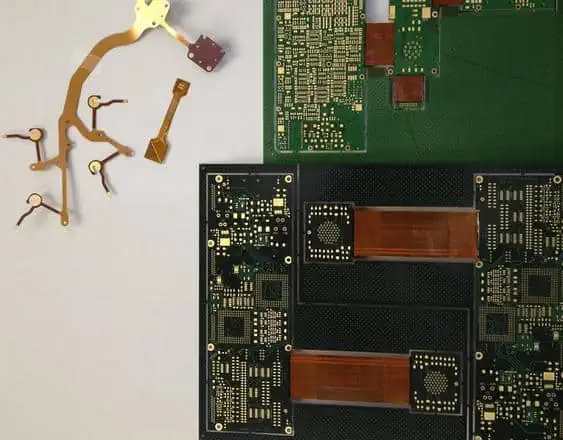

In typical PCB assemblies, wave soldering or hand soldering is frequently employed for through-hole components. However, these methods can present significant challenges for advanced designs. Circuit boards featuring Ball grid Array (BGA) components on both sides, high component density, or closely packed surface-mount technology (SMT) alongside through-hole elements can render traditional soldering methods unreliable or impractical.

While hand soldering provides versatility, it often lacks the consistency and repeatability essential for high-reliability applications, particularly those adhering to IPC Class 3 standards. On the other hand, wave soldering can incur substantial costs due to the necessity for custom fixtures and is frequently ill-suited for densely populated or thermally sensitive layouts.

For these intricate applications, automated selective soldering presents a distinct advantage. This technique ensures precise and repeatable soldering of through-hole components without jeopardizing adjacent SMT parts or necessitating extensive fixturing. Consequently, it leads to a more consistent and high-quality assembly process that satisfies the rigorous demands of critical-use electronics.

extensive PCB Assembly Solutions

San Francisco Circuits provides both turnkey and consigned PCB assembly services tailored to various sectors, including commercial, medical, and defense industries. With the ability to deliver rapid prototypes in as little as 24 hours, the company accommodates everything from single prototypes to large-scale production runs.

The assembly capabilities encompass:

- Rapid and urgent PCB prototype assembly

- Turnkey, partial turnkey, and consigned assembly models

- Processes compliant with RoHS and non-RoHS standards

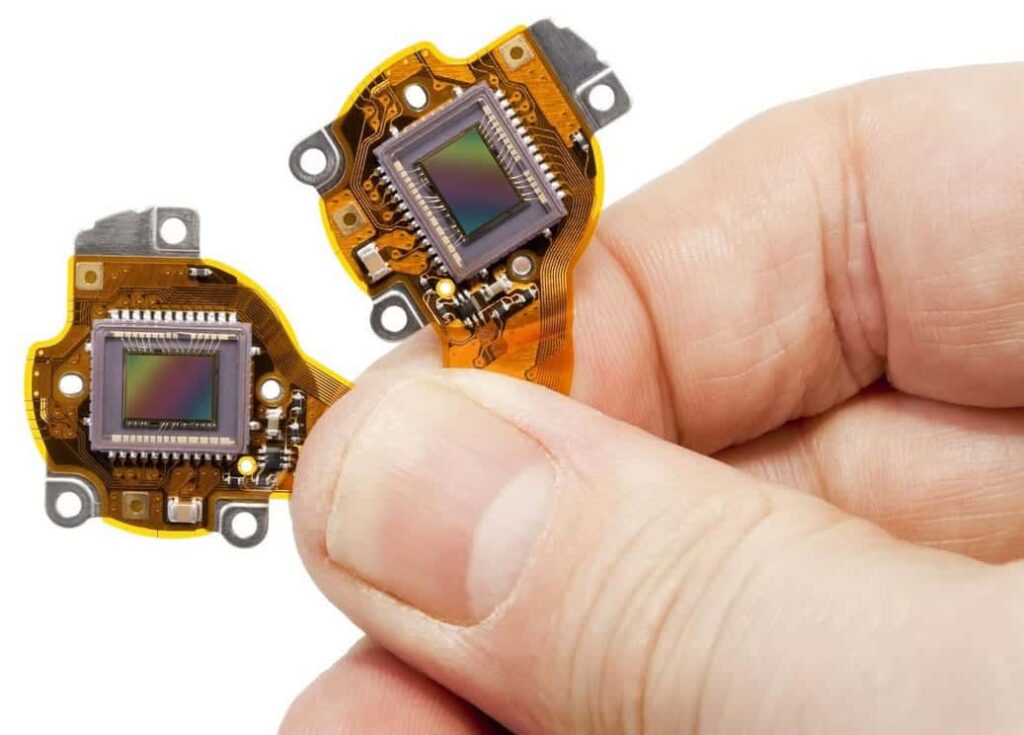

- High-precision component assembly down to 01005 size

- Integration of package-on-package (POP) and flip chip technologies

- functional and electrical testing

- Complete box build services

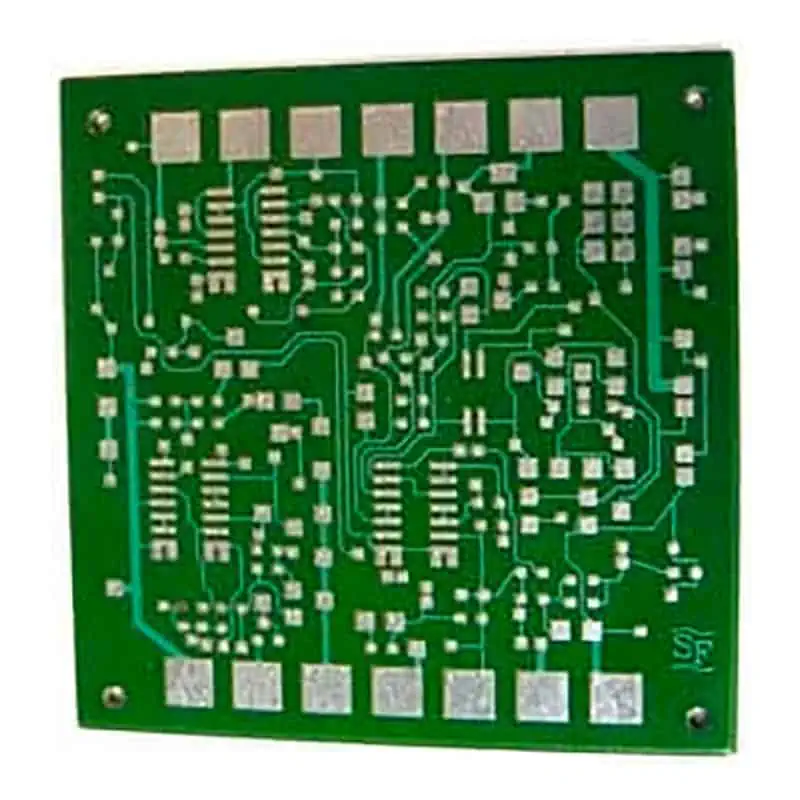

The company’s extensive knowlege extends beyond soldering and assembly, covering all phases of the PCB lifecycle—design, layout, fabrication, testing, and integration—making San Francisco Circuits a dependable partner for comprehensive circuit board production.

Streamlined Lead Times & Procurement Assistance

For clients providing their own components, assembly lead times generally range from 1 to 5 days. In turnkey scenarios, which encompass both procurement and assembly, the overall lead time includes the sourcing period, frequently enough maintaining a turnaround within a week.

Whether clients require assistance with sourcing rare components, managing their bill of materials (BOM), or calculating appropriate overages, San Francisco Circuits offers the necessary technical support to ensure efficient procurement and accurate inventory management.

Flexible Turnkey Assembly Options

Turnkey PCB assembly simplifies the production process by consolidating sourcing, logistics, assembly, and quality assurance under a single provider. This model alleviates the burden of managing multiple vendors and procurement stages. San Francisco Circuits meticulously oversees every aspect—from sourcing and shipping components to final assembly and inspection—providing peace of mind and saving time.

Available options include:

- Full Turnkey Assembly: Comprehensive management of component sourcing, PCB fabrication, assembly, testing, and shipping.

- Partial Turnkey Assembly: Clients supply selected components while the remaining tasks are managed in-house.

- Consignment Assembly: Clients provide all materials, while San Francisco Circuits handles the final assembly.

- Stocking Consignment: Materials are delivered in bulk and securely stored for future projects.

Each approach is designed for adaptability, assisting clients in achieving their production objectives while upholding stringent quality control standards.

The Rise of Turnkey Assembly Services

While consignment assembly was once the norm, many companies are now transitioning to turnkey services for enhanced efficiencies and reduced risks. By leveraging San Francisco Circuits’ robust supplier relationships, clients enjoy:

- Streamlined logistics and fewer sourcing delays

- Accurate overage planning to minimize waste

- Reduced internal labor for kitting and procurement

- Improved quality assurance from sourcing to final testing

- Accelerated production cycles and shorter time to market

With automated selective soldering and a comprehensive turnkey assembly offering, San Francisco Circuits is well-positioned to consistently deliver reliable, high-quality results for even the most complex PCB projects. The company remains a trusted ally for clients seeking precision, consistency, and expedited production in electronic manufacturing.