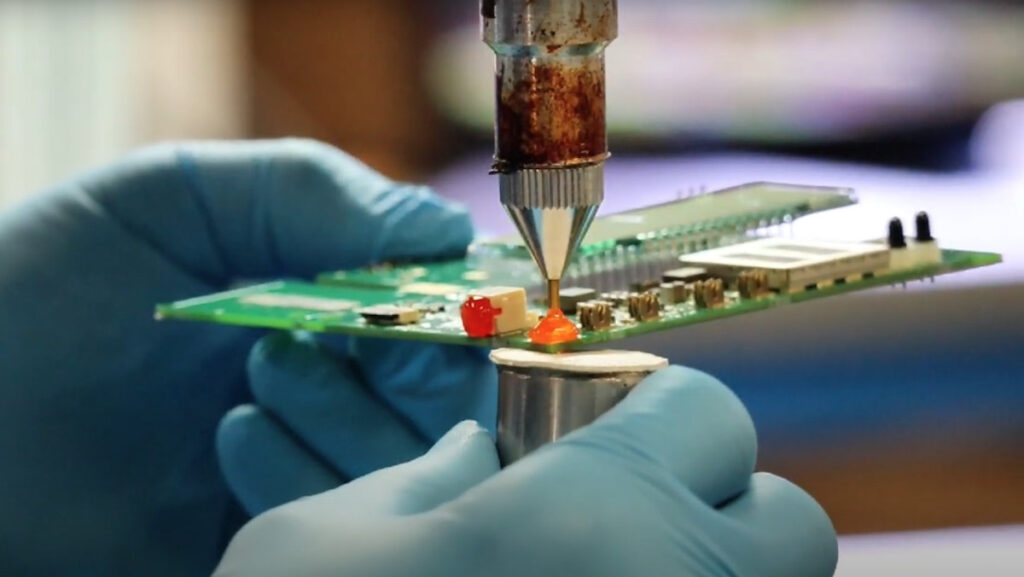

HZO’s advanced Guardian Parylene coatings deliver exceptional environmental protection for vital electronic components and printed circuit board assemblies utilized in unmanned aerial vehicles (UAVs), robotics, and other delicate systems.

These coatings are applied using a chemical vapor deposition (CVD) technique, resulting in a consistent, pinhole-free layer that adheres to every surface and edge. This process creates a robust barrier with notable dielectric properties, outstanding resistance to chemicals and wear, and minimal thermal expansion.

When formulating a budgetary estimate for a new Parylene coating initiative, HZO considers five critical factors to ensure that pricing aligns with both technical specifications and logistical needs.

1. Component Size

The initial factor to consider is the dimensions of the components. The size of the system influences how many parts can be processed in a single chamber load, which directly impacts coating throughput and production scheduling.

2. Masking Needs

The next aspect involves assessing the number and complexity of masking points. This includes areas such as ground pads, electrical connectors, or moving parts—any section that must remain uncoated with Parylene. The masking procedure can increase time and labor costs, affecting the overall budget.

3. projected Production Volume

Estimating the annual production volume is crucial for cost assessment. Knowing whether production will be continuous or in batches helps determine the number of coating runs needed weekly, monthly, or annually.

4. Location of Coating Application

Geographical factors also play a significant role in pricing. Depending on the manufacturing site or where coating services are needed,HZO evaluates options across its global facilities,including locations in the United States,China,Mexico,and Vietnam. If the location is adaptable,the most economical and efficient choice can be made.

5. Environmental Conditions

Lastly, the operational environment of the coated components influences the selection of coating formulation and thickness. Considerations such as exposure to corrosive gases, salt fog, or extreme temperatures must be factored in to ensure the coating meets the durability and protective requirements of the application.

By thoroughly examining these five factors, HZO customizes its quotes to align with both technical performance criteria and customer budget expectations.