Essential Factors in Electronic and PCB Interconnect Design

Designing a printed circuit board (PCB) that meets all performance criteria is a complex endeavor, especially when multiple interconnected boards are involved.This complexity is significantly heightened in multi-board systems.

As a leader in advanced PCB solutions, San Francisco circuits emphasizes the importance of strategic planning to enhance multi-board development while ensuring reliability and functionality remain intact.

critical Aspects of Multi-Board Systems

In systems comprising several boards, factors such as signal integrity, mechanical compatibility, and interconnect strategies become paramount. Proactive planning is crucial; careful consideration of connector locations, board stacking, and alignment can prevent costly design revisions and integration setbacks. The involvement of multiple boards increases the likelihood of cumulative tolerances and electrical discrepancies, which can adversely affect overall system performance.

Key Topics Covered

This article delves into the following areas:

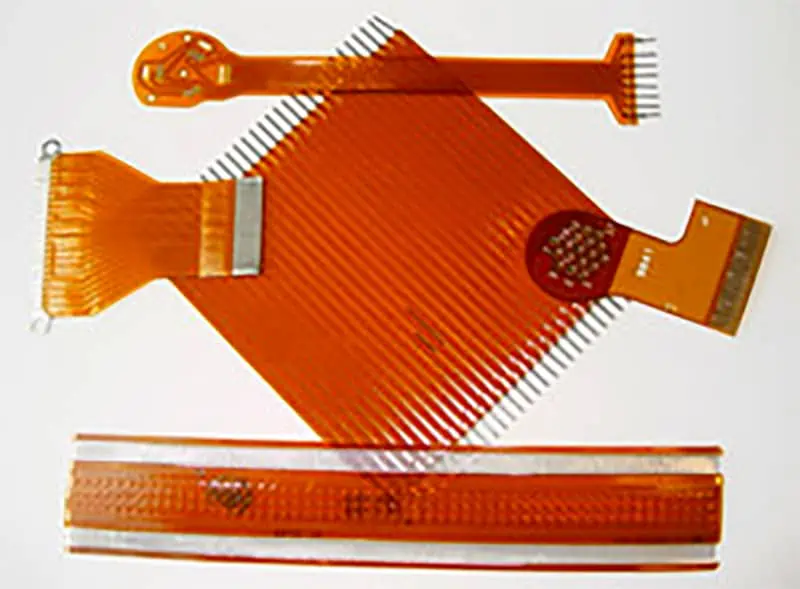

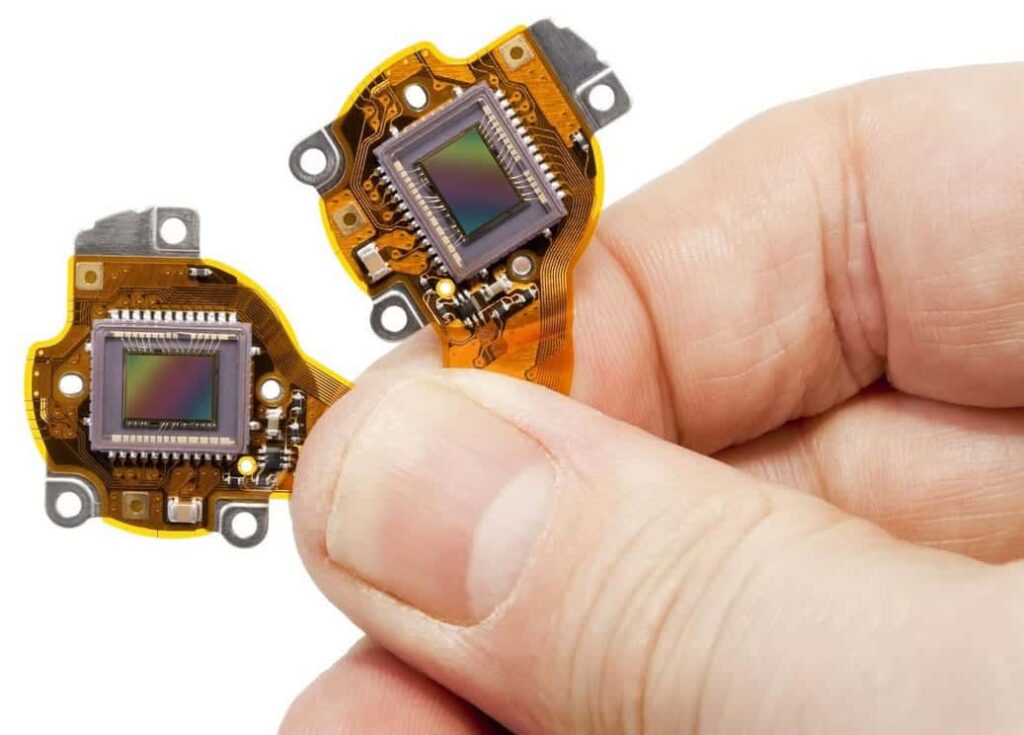

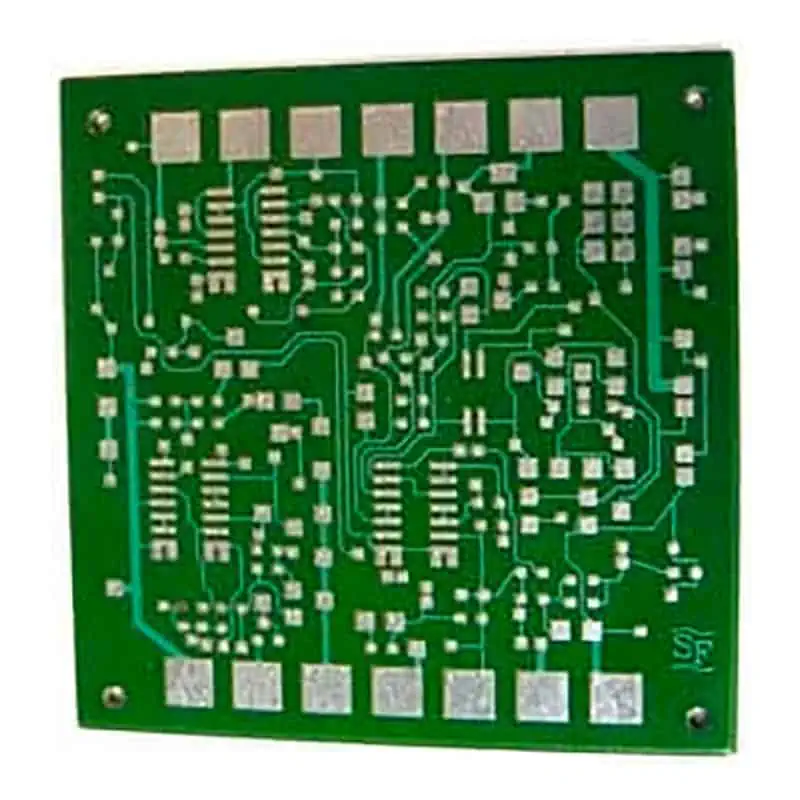

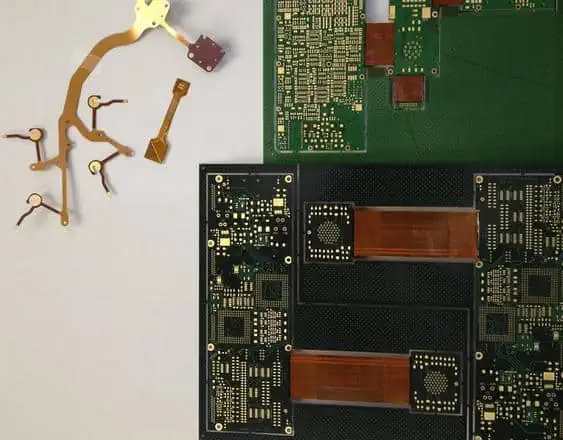

- Illustrations of Multi-Board Solutions

- Fundamental Design Principles for Reliable Interconnectivity

- Adhering to a PCB Design Workflow

- Considerations for Board Stacking

- Proactive PCB Testing Strategies

- Manufacturing and Service Considerations

- Designing for Efficient High-Speed Interconnectivity

enhancing Design Processes

By fostering strong partnerships with experienced suppliers and adhering to structured workflows, engineers can navigate the complexities of multi-board assemblies more effectively. this approach transforms a challenging process into a more manageable and predictable design cycle.

For further insights, read the original article or visit SFC’s website for additional information.