This article from Hargrave Technologies delves into the intricacies of electronic speed controllers (ESCs), highlighting the distinctions between bus current and phase current, the criteria for rating escs, and the complexities involved in powering these devices.

Understanding Bus Current and Phase Current

A frequently asked question regarding brushless DC motor (BLDC) electronic speed controllers (ESCs) pertains to the differences between bus current and phase current.

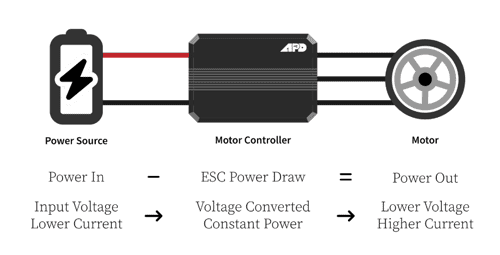

Bus current refers to the current supplied to the ESC from a battery or power source, while phase current is the current that the ESC delivers to the motor.

Hargrave technologies evaluates its ESCs based on their phase current output, making this distinction crucial.

The BLDC ESCs from Hargrave Technologies regulate motor speed by adjusting the voltage sent to the motor (known as phase voltage). This is achieved through a duty cycle that ranges from 0% to 100%, utilizing a method called pulse width modulation (PWM). The duty cycle directly influences the motor’s speed.

Motor RPM = KV × Duty Cycle % × Input Voltage

Why does this matter? An ESC cannot generate power; thus, the power entering the ESC (from the power source) must equal the power exiting to the motor.While there is a minor loss within the ESC, Hargrave Technologies’ models typically boast an efficiency greater than 95%.

The output voltage will always be lower than the input voltage. The ESC modifies the phase current to account for this difference (power in must equal power out).understanding the relationship between duty cycle and phase current is vital when designing a BLDC system.

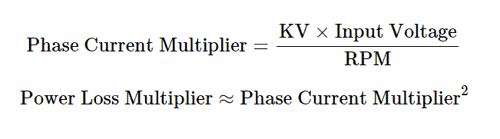

If the duty cycle is set too low, phase currents can surge rapidly (for instance, using a propeller that exceeds the capacity of a specific motor kV).

For instance, imagine a system drawing 50 V at 100 A from a battery. If the ESC is instructed to run at a 50% duty cycle, the output voltage to the motor will be 25 V. Consequently, the ESC will need to increase the output current to 200 A (since power in must equal power out; Power = Voltage × Current).

How ESCs Are Rated

Hargrave Technologies rates its ESCs based on the phase current they can sustain under both continuous and peak operating conditions. The heat generated by an ESC primarily depends on the current output at any moment.

Heat loss is calculated as the square of the phase current multiplied by the resistance of the unit. For more information on powertrain matching,further details can be found here. Utilizing higher voltages is advisable whenever possible, as this will reduce the current for a given power output.