Partnership between Volatus and American Robotics.

According to Specialty Coating Systems, the global semiconductor sector is experiencing remarkable growth, with the Semiconductor Industry Association projecting a 19.2% increase in 2024 compared to the previous year. Read more >>

Projections suggest that the market will surpass $1 trillion by 2030, driven by the rising demand for sophisticated electronics reliant on semiconductor technology. Despite their widespread use in contemporary devices, semiconductors face extreme conditions during both production and practical applications, highlighting the need for effective protective measures.

Addressing Corrosive Manufacturing Environments

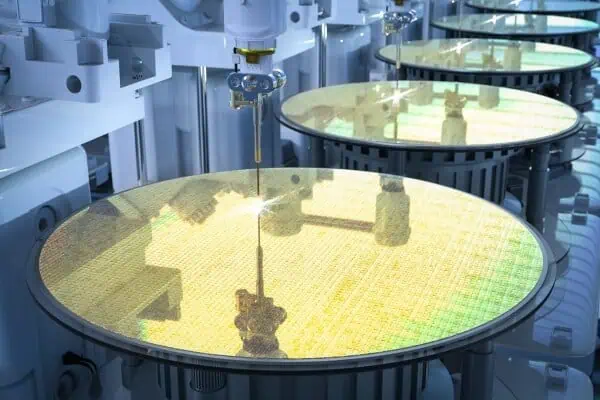

The process of semiconductor fabrication involves numerous complex steps, many of which expose components to highly corrosive environments.The aggressive slurries utilized in wafer layering and bonding create notable challenges, leading to premature wear of metallic components within manufacturing systems. Similarly, polishing tools that come into contact with these corrosive substances experience accelerated degradation, resulting in frequent and costly replacements.

To counter these issues, semiconductor manufacturers are increasingly turning to protective solutions that enhance the durability and efficiency of their equipment. Conformal coatings, especially Parylene, offer a robust defense against corrosive chemicals and environmental stressors.

By creating a uniform, ultra-thin protective layer, Parylene serves as a barrier against moisture, harsh chemicals, and electrical interference. One semiconductor manufacturer reported a 300-400% increase in component lifespan after adopting Parylene coatings, substantially lowering downtime and replacement expenses.

Safeguarding Semiconductor Components in Challenging Environments

In addition to manufacturing, semiconductor components must endure a variety of operational environments, including outdoor settings, industrial applications, and critical uses in aerospace and medical devices. Extreme conditions such as high humidity, exposure to reactive gases, and temperature fluctuations pose considerable risks to the reliability and longevity of electronic systems.

The distinctive properties of Parylene make it an ideal choice for ensuring the durability of semiconductors in these demanding situations. Its ability to conform to complex component shapes provides complete protection, while its customizable thickness allows for optimization based on specific application needs.

Whether protecting semiconductors in space exploration technologies or precision medical devices, Parylene coatings consistently deliver outstanding performance and reliability.

The Future of Semiconductor Protection

As the semiconductor industry evolves, the demand for dependable protective solutions continues to rise. Conformal coatings like Parylene will remain crucial in extending the operational lifespan of semiconductor components, minimizing maintenance costs, and ensuring reliable performance in even the most challenging environments.

By incorporating these advanced coatings into semiconductor manufacturing and deployment strategies, industry leaders can bolster system resilience and maintain a competitive advantage in the rapidly changing electronics landscape.

Explore the original article or visit the SCS website for more data.