India-based drone startup VECROS is making significant advances in aerial robotics with its autonomous UAV platform, ATHERA1, developed using HP Additive Manufacturing (AM) Multi Jet Fusion (MJF) 3D printing technology.

Founded in early 2021 by graduates from IIT Delhi and NIT Nagpur, VECROS is the country’s first Spatial AI drone startup, aiming to deliver intelligent, fully autonomous drones capable of operating in GPS-denied environments. ATHERA1 represents autonomy level 4 capability, enabling the UAV to avoid obstacles and perform complex tasks without human intervention or external navigation systems.

Developed from prototypes created while its founders were still students, VECROS now leads India’s efforts in next-generation autonomous flight. The company’s mission is to build the world’s most intelligent flying machines by integrating Spatial AI to allow drones to navigate complex 3D environments safely and efficiently.

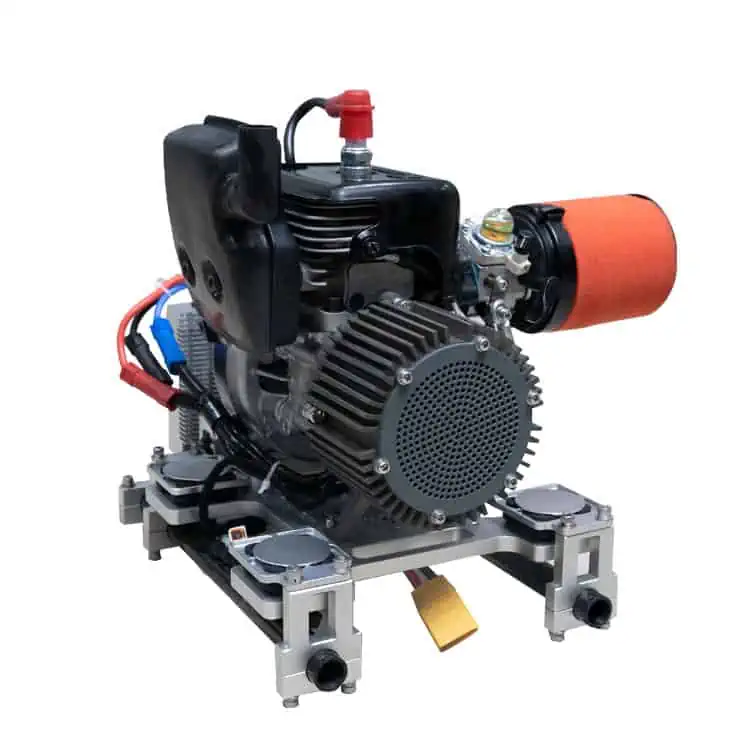

To bring ATHERA’s advanced design to life, VECROS adopted HP’s MJF 3D printing solution. Initially experimenting with FDM printing, the team found surface quality and material limitations to be a constraint. “When we started designing ATHERA, we weren’t aware of other additive manufacturing techniques apart from FDM,” explains Rajeshree Deotalu, CTO of VECROS. After exploring alternatives like SLA and SLS, the company turned to HP MJF for its superior finish, structural integrity, and design flexibility.

“We focused on HP MJF because the MJF process doesn’t require support structures, and it provides high flexibility in terms of build plate dimension,” says Deepak Kumar, Head of Hardware at VECROS. “It gives us the flexibility to make our design more aesthetically appealing. For example, the manufactured components have a smoother surface finish with less layer visibility. It is also less brittle.” VECROS uses HP 3D High Reusability PA 12 material and post-processes components with PU paint.

According to Rajesheree and Deepak, “HP’s MJF process has given us the flexibility to add all features and working mechanisms we need without spending too much time and money.”

CEO Besta Prem Sai added, “This current look and feel are what we initially intended. This looks quite promising. And we have successfully tested it in the field.”

With proven performance, ATHERA is already driving innovation in sectors such as mining, construction, oil and gas, telecommunications, and infrastructure surveillance, positioning VECROS at the forefront of autonomous aerial solutions.

HP Additive Manufacturing and Redington will be exhibiting at Drone International Expo 2025 in India, July 31-1 August, 2025. Visit HP Additive at Hall No. 12, booth D40 and D41, to learn more about how their advanced 3D printing solutions are driving innovation in UAV design and manufacturing across the region.