HP Additive Manufacturing Solutions is a world-leading developer of 3D printing technologies that empower the drone industry with unprecedented levels of innovation and customization ability.

The Trusted AM Solutions for Drones. Built for Performance, Scale & Innovation.

Our industrial-grade additive manufacturing systems enable rapid production of parts ranging from functional prototypes to final production components with consistent dimensional accuracy and isotropic material properties.

HP’s technology achieves the lowest component weights in additive manufacturing, producing lighter structural components, fuselages, and entire wings than any other provider. This capability stems from advanced design freedom and scalability inherent in the process. HP’s Digital Manufacturing Network (DMN) integrates a global network of partners, enabling distributed production and streamlined supply chains for complex aerospace parts. The end user can send their CAD file and get their parts printed with the quality and standard expected from HP Additive Manufacturing Solutions.

- HP Multi Jet Fusion Technology

- HP Jet Fusion 5600 Series

- Case Studies & Applications

HP Multi Jet Fusion Technology

Our HP Multi Jet Fusion (MJF) technology revolutionizes drone manufacturing, enabling unparalleled rapid prototyping and parts customization capabilities. Utilizing a unique multi-agent and multi-pass process and controlling the properties of each individual voxel in every print, it allows you to combine fine detail with optimal mechanical properties, creating complex geometries that are impossible to produce with CNC machining.

Watch the video below to find out more about the HP MJF process:

Featured Solution: HP Jet Fusion 5600 Series

Industrial 3D Printers for Drones & Robotics

The HP Jet Fusion 5600 Series enables high-volume production of robust 3D printed parts, allowing you to efficiently scale up your drone manufacturing capabilities. Compatible with a variety of materials including flame-retardant and smooth surface finish options, it offers an effective build volume of 380 x 284 x 380 mm and a building speed of up to 3466 cm3 per hour.

The capabilities of this powerful printer can be enhanced further with our HP 3D Process Development package. The Process Development workflow allows you to customize and fine-tune critical process parameters according to specific application requirements, and to analyze and iterate until your drone parts are exactly optimized. The final settings can then be sent to the HP Jet Fusion 5600 to ensure the highest levels of repeatability at scale.

HP Additive Manufacturing Solutions: Case Studies & Applications

Seed-Planting Drones

HP MJF technology is utilized by Inverto Earth AG to print 3D parts for drones that release seeds for the restoration of coastal ecosystems such as mangrove forests. The design freedom offered by MJF allows the release mechanism to be easily adapted to accommodate more than 60 different types of seed, while ensuring that the parts are durable enough to withstand harsh and muddy environments.

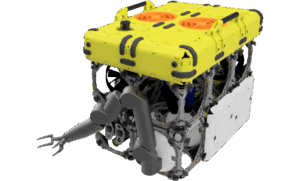

Modular UUVs

UUV (unmanned underwater vehicle) technology developer Framework Robotics creates modular systems for a wide range of marine applications including oil and gas, defense, and renewable energy. HP MJF technology allows the company to overcome the delamination, waterproofing and longevity issues faced by FDM-printed components, while ensuring that they can provide faster turnaround times for their clients.

Last-Mile Delivery Drones

Blueflite employs HP Multi Jet Fusion technology to produce 3D-printed components for its lightweight delivery drones. The use of HP Nylon 12 material enables a 25% reduction in fuselage weight while maintaining strength. MJF’s high-resolution printing supports complex structures like ribs and lattices, improving durability and design flexibility for parts such as body panels, motor mounts, and landing gear.

Autonomous AI-Powered Drones

VECROS uses HP Multi Jet Fusion to manufacture parts for ATHERA, an autonomous UAV equipped with onboard AI for obstacle avoidance and real-time data collection. HP MJF offers the smooth surface finish, durability, and design flexibility needed for integrating multiple payloads, enabling rapid prototyping and design optimization to meet the company’s advanced operational requirements.