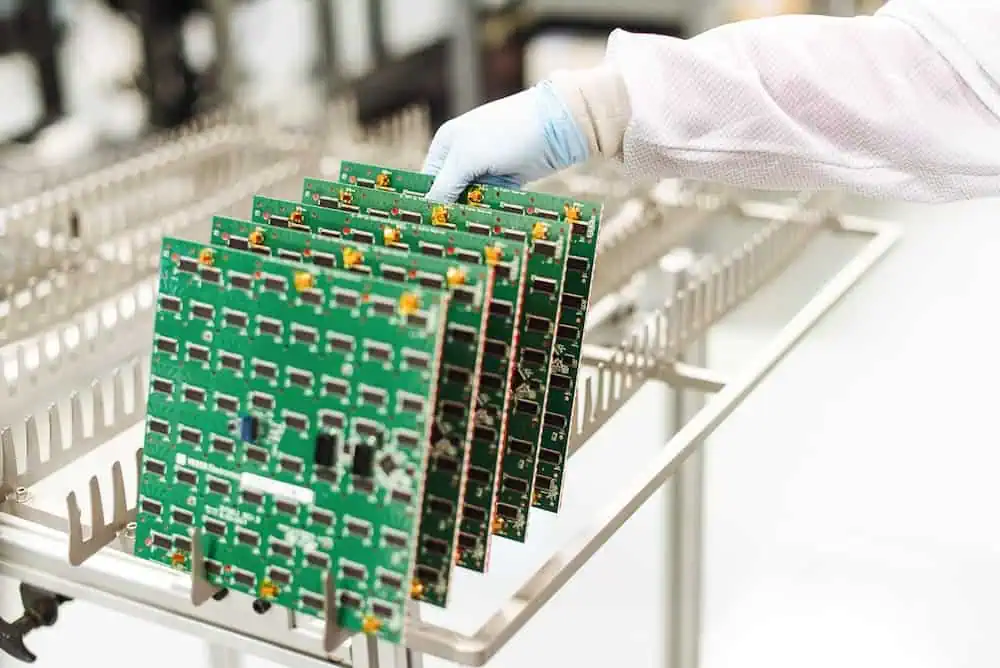

HZO stands as an ITAR-certified leader in providing ultra-thin conformal coating solutions designed to safeguard mission-critical electronics and PCB assemblies in UAVs (unmanned aerial vehicles) and robotics.

Our advanced coatings are perfectly suited for drone manufacturers and systems integrators aiming to boost the durability and reliability of their products, even in the most extreme conditions. They are also tailored for high-volume manufacturing needs.We present a diverse range of options, including conformal coatings that comply with ASTM and military specifications.

We provide comprehensive turnkey solutions that guarantee reliable protection for your electronics, customized to meet your manufacturing and budgetary needs. Our established processes combine expert knowledge with cutting-edge materials science and advanced equipment, enabling us to handle production runs of any scale, accommodating quantities of up to millions of units.

Lightweight, Ultra-Thin Coatings for Drones and Robotics

Our thin-film coatings offer a lightweight choice to traditional bulkier methods like potting, adding negligible weight to the assembly. This results in highly dependable electronic systems without affecting SWaP (size, weight, and power) parameters, payload capacities, or flight durations.

Conformal coatings shield sensitive electronics in drones and robotic systems from various environmental threats that can lead to shorts, corrosion, and other failures. These threats include:

- Rain and snow

- Dust

- Salt spray

- Humidity

- Pollutants and chemicals

- Extreme temperatures

HZO’s durable hydrophobic coatings provide superior resilience in even the most demanding conditions faced by industrial, aerospace, and military-grade systems, ensuring your UAVs and autonomous vehicles continue to function when failure is not an option.

Discover more: conformal coatings for drones

which Conformal Coating is Ideal for Drones? Explore our insightful blog that delves into the characteristics of parylene conformal coatings and identifies the best coating solutions for drones.

Coating Solutions for Rugged Electronics

We provide a range of lightweight and ultra-thin conformal coatings tailored to meet diverse operational needs.

HZO Guardian Series

Parylene Thin-Film Conformal Coatings

Our Guardian ultra-thin parylene coatings are applied through a chemical vapor deposition (CVD) process, creating a highly uniform, pinhole-free protective layer that envelops every edge and crevice.These films typically range from 2 to 25 microns in thickness, providing robust protection against water damage, corrosion, and electrical failures while using substantially less material than traditional coatings.

Parylene boasts numerous advantageous properties, including excellent dielectric performance, high abrasion resistance, superior chemical resistance, and minimal thermal expansion. Its low outgassing levels make it particularly suitable for satellite and space applications.

Learn more: Guardian parylene thin-film conformal coatings

HZO Sentinel Series

Plasma-Based Nanocoating

Sentinel plasma-applied nanocoatings offer protection at the molecular level, making them ideal for coating printed circuit board assemblies (PCBAs) and individual connectors and semiconductors.

These economical hydrophobic coatings defend against a wide array of liquids and gases while ensuring that your electronics adhere to weight restrictions and precise thickness specifications.

Learn more: Sentinel plasma-applied nanocoatings

For personalized guidance on selecting the right coating solution for your specific drone or robotic vehicle submission, please reach out for expert assistance.