Voliro understands that industrial inspections have long been a costly and time-intensive process, particularly for high-risk assets such as columns and piping in chemical plants. Read more >>

Traditional methods often involve complex scaffolding or rope access teams, leading to increased labor costs, extended downtime, and safety risks. However, the landscape is rapidly evolving with the advent of aerial robotics, offering a safer, faster, and more cost-efficient alternative.

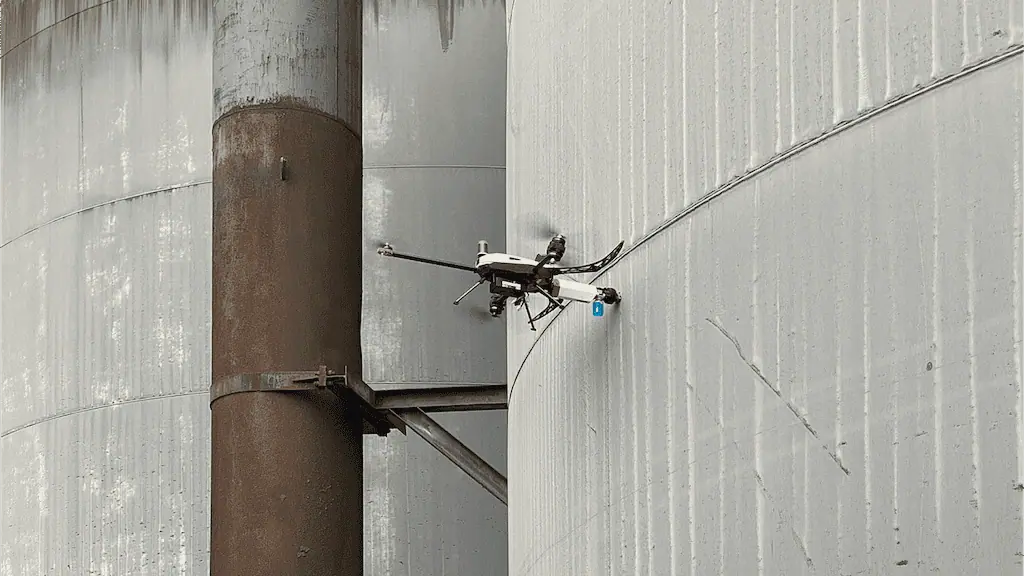

At the forefront of this transformation is Voliro, a leader in aerial robotic solutions for height-related inspection tasks. Equipped with specialized Non-Destructive Testing (NDT) sensors, Voliro’s drones deliver high-precision data collection while minimizing operational disruption. The Voliro T drone, in particular, has proven instrumental in driving efficiency gains for industrial inspection applications.

Bilfinger’s Deployment of the Voliro T Drone

In a recent deployment at a chemical plant, Bilfinger leveraged the Voliro T drone to conduct a thorough inspection of three columns and associated piping.

These assets undergo annual assessments as part of the plant’s ongoing integrity management program. Typically, such inspections require significant downtime and extensive manpower due to the complexity of accessing curved piping and high-elevation structures.

By integrating Voliro T drone technology, Bilfinger was able to complete the inspection in just 2.75 days, a stark contrast to the 8-day timeframe required using traditional rope access methods. This rapid execution not only reduced plant disruption but also delivered substantial cost savings.

Cost Reduction and Workforce Optimization

One of the most significant benefits realized during the inspection was a 30% reduction in overall costs. This cost efficiency stemmed from multiple factors:

- Reduced manpower: Traditional inspections necessitate at least three personnel for rope access operations. With the Voliro T drone, only a two-person team was required, lowering labor costs.

- Minimized equipment needs: Eliminating the need for scaffolding or complex rigging systems translated into direct financial savings.

- Accelerated data collection: The drone’s ability to quickly navigate and scan hard-to-reach areas enabled faster decision-making and a more streamlined inspection workflow.

Advancing Ultrasonic Testing for Industrial Assets

A key component of the inspection was ultrasonic testing (UT), a widely recognized NDT method that uses high-frequency sound waves to assess material properties and measure wall thickness.

The Voliro T drone, equipped with a UT payload, efficiently gathered precise measurements on the plant’s piping and column structures, particularly in 90-degree bends where corrosion risks are heightened.

Bilfinger’s deployment included two specialized probes:

- Standard UT probe: Measures thickness in the range of 2 – 150 mm (0.08 – 5.9 in).

- High-Temp UT probe: Operates at temperatures from 0 – 260°C (32 – 500°F), eliminating the need to cool assets during inspections.

By leveraging these capabilities, the Bilfinger team ensured a comprehensive integrity assessment while maintaining operational uptime.

A Step Toward Industry-Wide Adoption

The success of Bilfinger’s Voliro T drone deployment underscores the broader shift toward robotic solutions in industrial maintenance. With enhanced safety, cost efficiency, and precision, such technologies are poised to become an industry standard for NDT inspections.

Looking ahead, Bilfinger’s client has expressed strong interest in further integrating drone-based solutions into their long-term maintenance strategy. This initiative not only enhances asset reliability but also aligns with the industry’s drive for digital transformation and sustainability.

By pioneering the adoption of cutting-edge robotic technology, Bilfinger is setting a new benchmark for efficiency and innovation in industrial inspections — demonstrating that the future of asset integrity management is airborne.

Read the original article, or visit the Voliro website for more information.