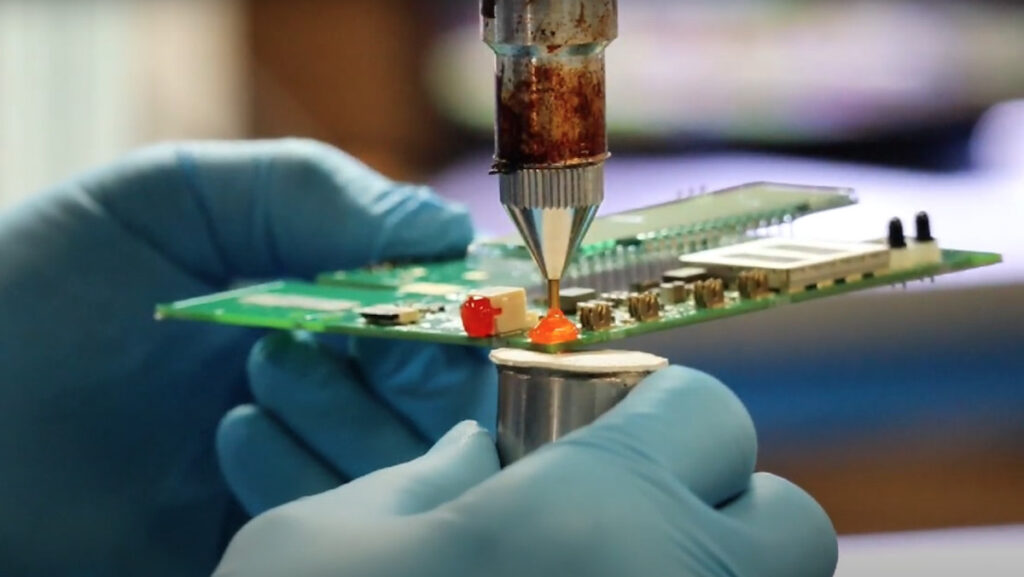

HZO’s ultra-thin Guardian Parylene coatings provide robust environmental protection for critical electronic components and printed circuit board assemblies in unmanned aerial vehicles (UAVs), robotics, and other sensitive systems.

These coatings are applied through a chemical vapor deposition (CVD) process, forming a uniform, pinhole-free layer that conforms to every surface and edge. The result is a durable barrier with strong dielectric properties, excellent resistance to chemicals and abrasion, and minimal thermal expansion.

When preparing a budgetary quote for a new Parylene coating project, HZO evaluates five key factors to ensure pricing aligns with technical and logistical requirements.

1. Part Dimensions

The physical size of the components is the first consideration. System dimensions help to determine how many parts can be processed in a single chamber load. This directly affects coating throughput and production planning.

2. Masking Requirements

Next, the number and complexity of masking points are reviewed. These may include ground pads, electrical connectors, or moving parts—any surface or region that must remain free of Parylene. The masking process can add time and labor, impacting overall cost.

3. Annual Production Volume

The projected volume over a year plays a major role in cost estimation. Understanding whether production will be continuous or batch-based helps calculate the number of coating runs required per week, month, or year.

4. Coating Location

Geographic considerations also affect pricing. Depending on where manufacturing takes place—or where coating services are required—HZO will evaluate options across its global facilities, including those in the United States, China, Mexico, and Vietnam. If location is flexible, the most cost-effective and efficient option can be selected.

5. Application Environment

Finally, the operational environment of the coated components will determine the appropriate coating formulation and thickness. Factors such as exposure to corrosive gases, salt fog, or thermal extremes must be taken into account. This ensures the coating is matched to the durability and protective requirements of the application.

By analyzing these five elements, HZO tailors its quotes to meet both technical performance standards and customer cost targets.