This article delves into the concept of motor winding resistance, its testing methods, and its applications in enhancing yoru projects, as explained by Tyto Robotics.

Contents Overview

- Understanding Motor Winding Resistance

- Impact of Winding Resistance on Motor Efficiency

- Conducting a motor Winding Resistance test

- Leveraging Motor Winding Resistance in Your Projects

1. Understanding Motor Winding resistance

Motor winding resistance refers to the inherent property of the wire coils that constitute the stator and rotor in electric motors. it quantifies the extent to which these coils resist the flow of electric current.

This resistance leads to a portion of electrical energy being transformed into heat, which can diminish motor efficiency. excessive heat generation may result in motor overheating and potential failure,making it crucial to maintain winding resistance within acceptable limits.

Factors influencing winding resistance include the wire’s length,cross-sectional area (gauge),resistivity,and the number of coil turns. Additionally,temperature plays a significant role; as temperatures rise,resistance increases due to heightened vibrations and collisions among metal ions.

2. Impact of Winding Resistance on Motor Efficiency

The winding resistance of an electric motor is pivotal in shaping its performance attributes. Elevated winding resistance can lead to diminished power output, reduced efficiency, and increased thermal losses.

On the other hand, lower winding resistance may cause excessive current draw, risking damage to the motor and its components. Therefore, regularly measuring and monitoring winding resistance is essential for ensuring optimal motor performance and preventing potential failures.

Typically, winding resistance is assessed by measuring the voltage and current in the motor, with calculations based on Ohm’s law, which states that resistance equals voltage divided by current.

This assessment can definitely help identify coil faults, such as short circuits or broken wires, and diagnose other motor issues, including bearing or drive circuitry problems.

3. Conducting a Motor Winding Resistance Test

A straightforward method to measure motor winding resistance is by using an ohmmeter or multimeter. Here’s a step-by-step guide.

Steps to Measure Motor Winding Resistance with a Multimeter:

- Ensure the motor is powered off.

- Access the motor winding: you may need to remove a cover or disassemble parts of the motor.

- Locate the winding terminals: refer to the motor’s wiring diagram or terminal markings to identify the start and end points of the winding.

- Activate the ohmmeter/multimeter: if using a multimeter, select the ohmmeter setting and choose an appropriate range for the expected resistance. If uncertain, start with the highest range and adjust downwards.

- Connect the probes: attach the meter’s probes to the winding terminals, ensuring good contact and checking for short circuits.

- Apply a test current through the wire: select a test current that does not exceed 10% of the nominal winding current.

- Record the resistance: note the resistance value displayed on the meter.If it falls within the manufacturer’s specified range, the winding is likely functioning correctly. values outside this range may indicate issues.

- Calculate the winding resistance: use Ohm’s law to determine resistance by dividing the voltage applied to the winding by the resulting current. As a notable exmaple, if the voltage is 10 volts and the current is 1 ampere, the winding resistance is 10 ohms (R = V/I).

- Repeat the test: for accuracy,conduct the test multiple times and average the results.

4. Leveraging Motor Winding Resistance in Your Projects

Manufacturers provide winding resistance specifications to help users understand the electrical characteristics and performance capabilities of their motors.

Here are several ways to utilize motor winding resistance in your projects:

- Creating a Motor Model: Winding resistance can assist in developing a theoretical model of your motor, which is beneficial during the design phase. Understanding the winding type (wye or delta) is also crucial. Though, discrepancies between experimental and theoretical models can occur, so testing with a thrust stand is advisable for accurate performance estimation.

- Validating Motor Design: Users can confirm that their motor aligns with the design and performance specifications provided by the manufacturer. Measuring winding resistance allows for verification of wire gauge, number of turns, and other design parameters.

- enhancing Motor performance: Winding resistance aids in selecting suitable drive circuitry and load characteristics for optimal performance. Higher resistance can lead to increased heating and lower efficiency, while lower resistance may cause excessive current draw and potential motor damage.

- Identifying Motor Faults: A significant deviation from the specified resistance value may indicate issues such as broken or shorted windings.

- Choosing the Right motor-Propeller Pairing: Motors with higher winding resistance generally exhibit lower torque but can achieve higher speeds with smaller propellers, while those with lower resistance provide higher torque, making them more suitable for larger propellers.

- Calculating Motor Efficiency: By measuring current draw and voltage across the motor, users can determine the power consumed. Winding resistance can be used to calculate power lost as heat, allowing for efficiency estimation by comparing consumed power to dissipated power.

Conclusion

understanding motor winding resistance is invaluable for your projects, and measuring it with a multimeter is straightforward.

This knowledge can guide you in selecting the right motor and propeller combination, designing effective motor drive circuitry, diagnosing motor faults, and calculating efficiency.

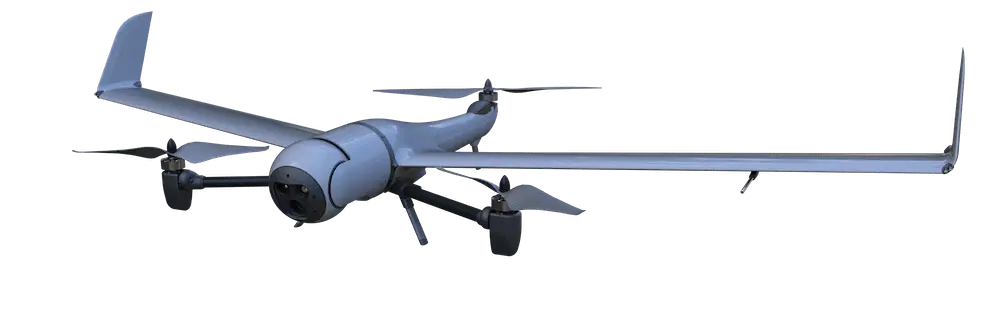

By factoring in winding resistance alongside other electrical characteristics, drone builders can enhance their drone’s performance and ensure reliable operation.

To begin characterizing your electric motors, explore our range of motor testing tools:

-

Series 1585

– measures up to 5 kgf of thrust / 2 Nm of torque

-

Flight Stand 15/50

– measures up to 50 kgf of thrust / 30 Nm of torque

-

Flight Stand 150

– measures up to 150 kgf of thrust / 150 Nm of torque