Ensuring the integrity of electronic signals is vital for the dependable functioning of autonomous vehicles. Shielding becomes increasingly crucial when unmanned systems operate in environments filled wiht electromagnetic interference. This article from Nicomatic presents essential strategies for enhancing the performance of shielding in wiring harnesses, focusing on established methods and best practices in the industry.

The Meaning of Shielding

Effective shielding is crucial for protecting the communications of unmanned systems from electromagnetic and radio frequency interference (EMI/RFI). When implemented correctly, these protective layers ensure that signal integrity remains intact. The use of metallic materials, properly grounded through conductive connectors, serves as the backbone of successful shielding solutions.

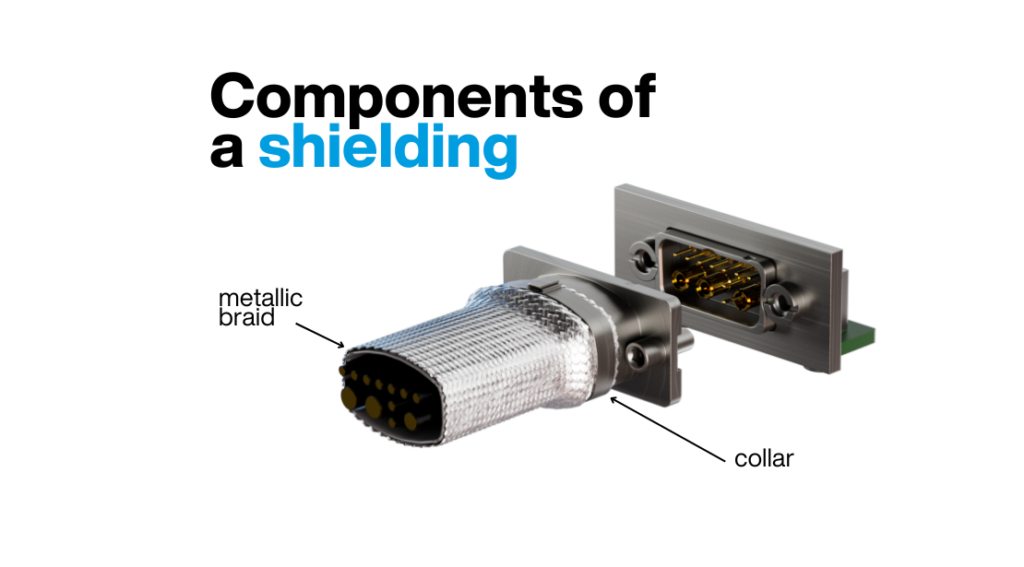

Essential Components of Shielding

-

Selection of Conductive Braid Materials: Opting for compatible metals for both the braid and connector is key to achieving optimal performance.

-

Density of Coverage: High-density braiding is essential for maintaining shielding effectiveness across cable bundles.

-

Correct Sizing: The diameter of the braid must be suitable for the underlying wires to ensure complete protection.

-

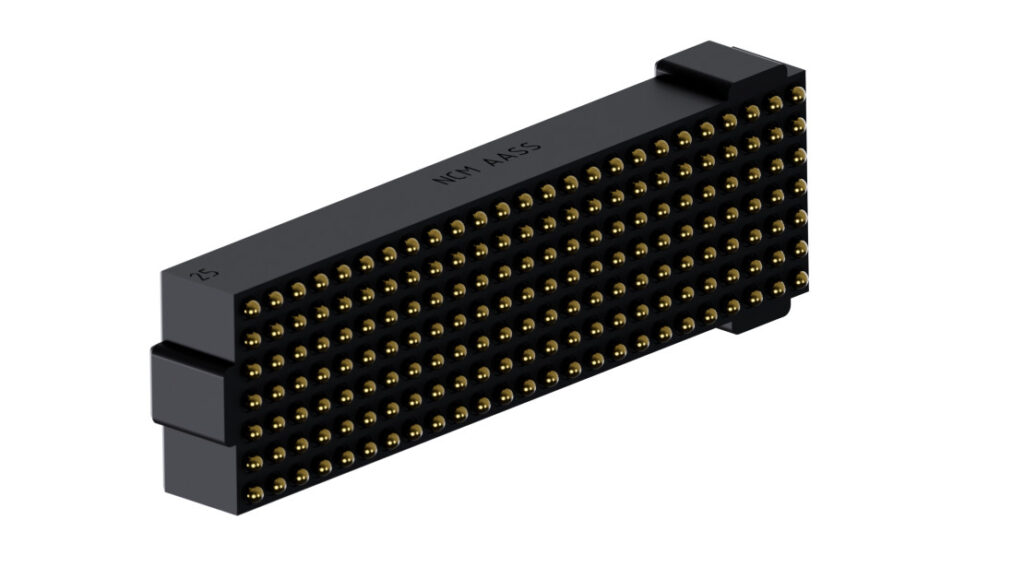

Integration of Metal Connector Backshells: A secure attachment of the braid to the connector shell via backshell is vital for ensuring strong, stable connections.

Techniques for Braid-to-Connector Attachment

-

Utilizing Metal Collars: These are recommended for securing braids around connector chimneys, effectively reducing potential entry points for interference.

-

Improving Contact Surfaces: Collars shoudl apply firm pressure to braids against chimneys. Textured chimney surfaces can enhance retention.

-

optimal Chimney Design: Circular or oval shapes allow for better collar fitting, ensuring complete contact without gaps.

Quality Assurance and Verification

-

Laboratory Testing: Validate material selections and techniques through comprehensive testing to meet transfer impedance (Zt) and resistance standards. Zt, calculated as Vin/Iout, assesses a cable’s resilience to EMI. Conduct specific transfer impedance tests to ensure optimal shielding performance. Visual inspections following IPC A620 standards help confirm overall shield quality.

-

Manufacturing Oversight: Implement rigorous production checks to ensure all harness assemblies comply with required standards. IPC guidelines provide valuable benchmarks for acceptable practices.

Implementing effective shielding in wiring harnesses is vital for safeguarding the electronic signals of unmanned systems against interference. By following these guidelines, engineers can significantly improve the reliability and performance of autonomous vehicles operating in challenging electromagnetic environments.

For the complete article, click here, or visit the Nicomatic website for more data.